Automatic weighing system and method

An automatic weighing and weighing technology, applied in the electromechanical field, can solve the problems of inconvenient weight information summary statistics and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

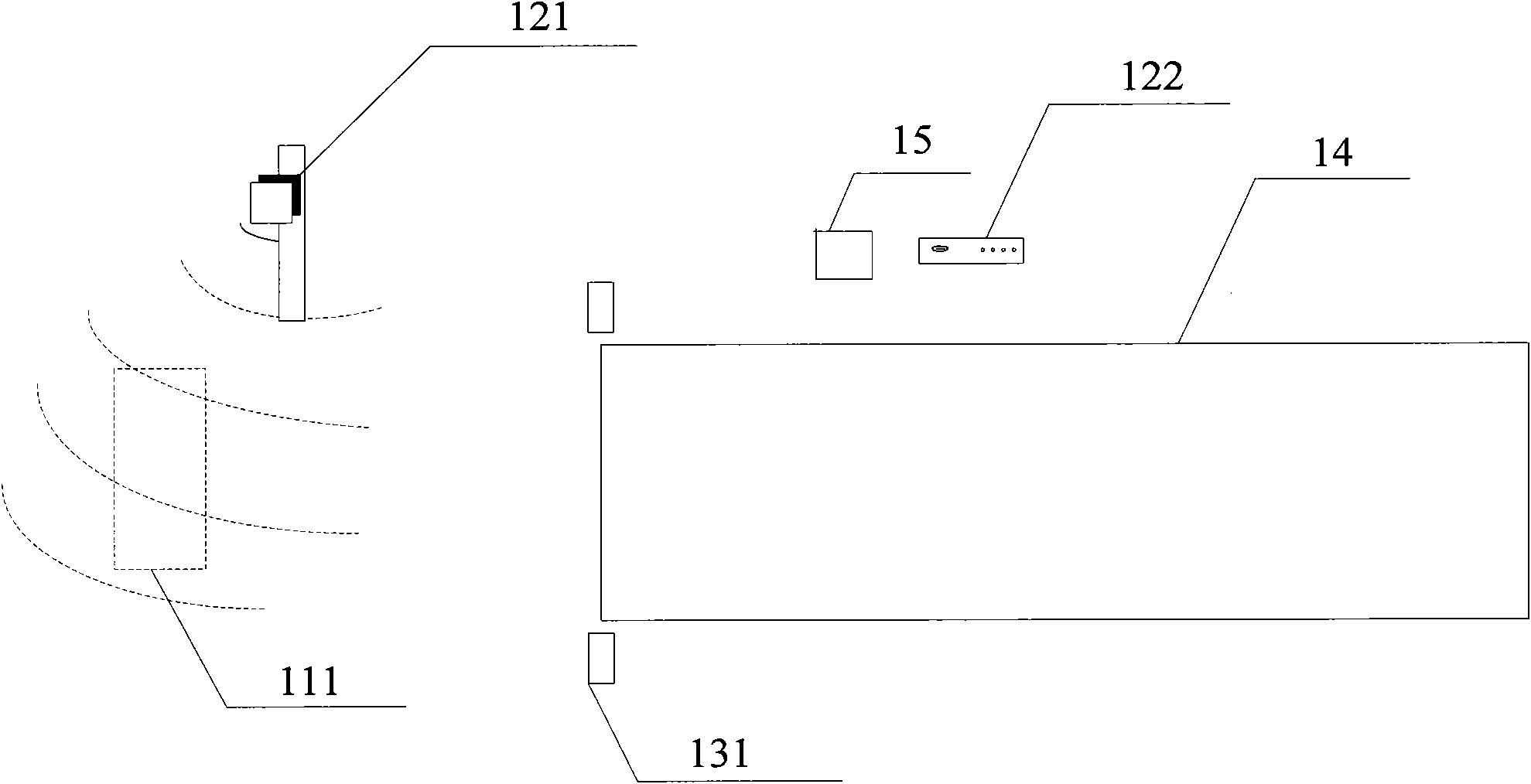

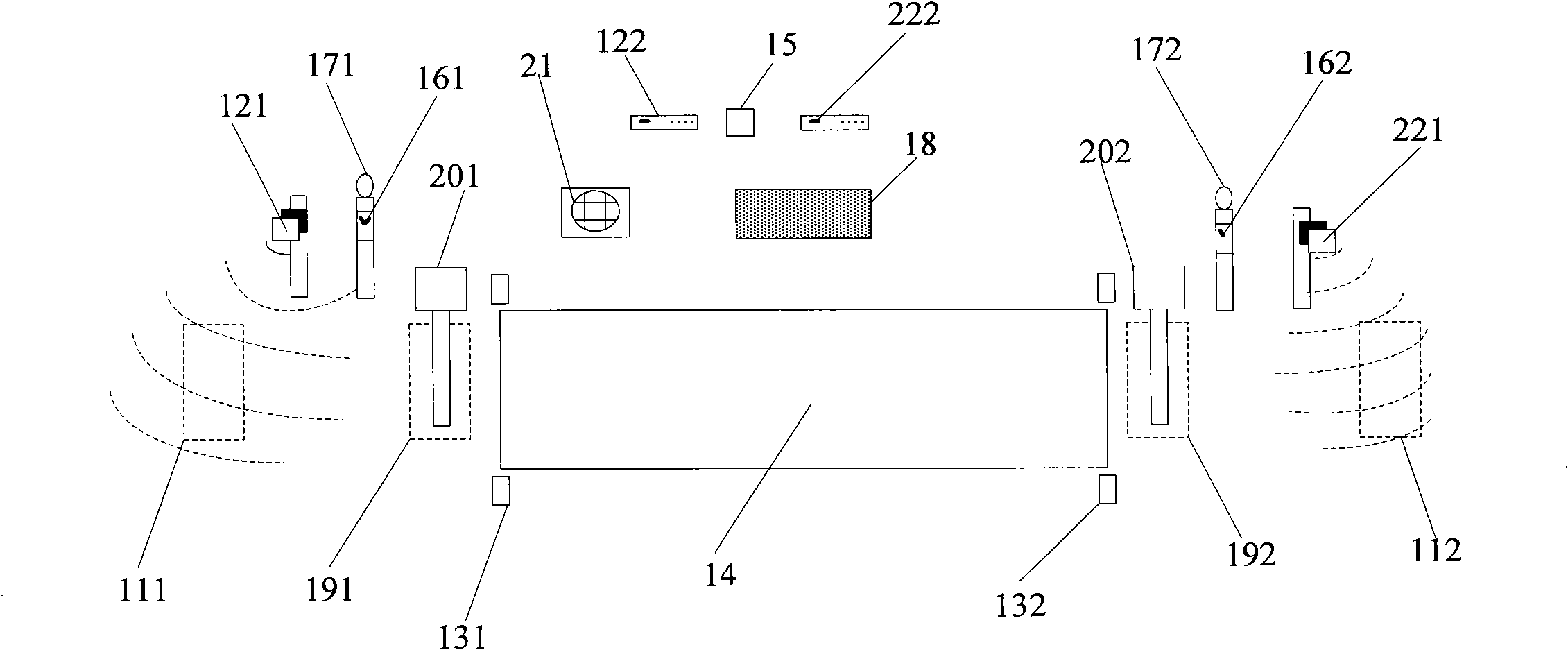

[0046] This example can be applied to figure 1 The automatic weighing system shown, such as Figure 9 As shown, it is a schematic flow chart of the first embodiment of the automatic weighing method of the present invention, which may include the following steps:

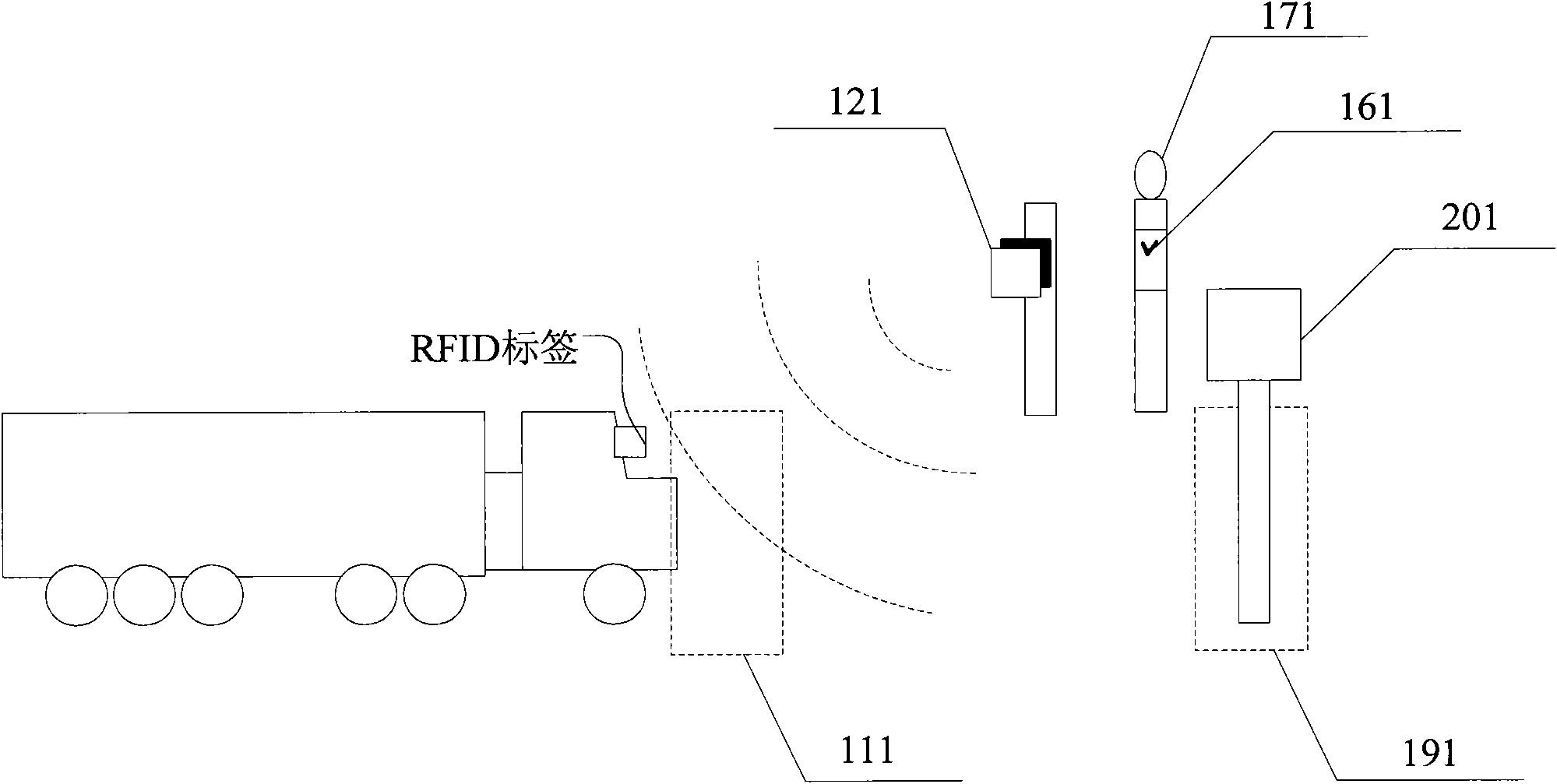

[0047] Step 91, when the first vehicle sensing unit detects that the current weighing vehicle enters the automatic weighing system, the first radio frequency identification unit obtains the RFID tag of the current weighing vehicle, and the control unit verifies the RFID tag;

[0048] Step 92: After the control unit has passed the RFID tag verification, when the first infrared radiation unit detects that the current weighing vehicle is completely on the electronic scale, it obtains the weight information of the current weighing vehicle, and the weight information of the current weighing vehicle is consistent with the current scale. RFID tag association for heavy vehicles.

[0049]In this embodiment, when the first v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com