Intelligent management platform for electric safety tools

A technology of intelligent management and power safety, applied in the direction of instruments, time registers, data processing applications, etc., can solve the problems of increased labor cost, inconvenient query, damage to tools and other problems caused by manual on-duty, so as to reduce the number of manual on-duty posts and save labor costs , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

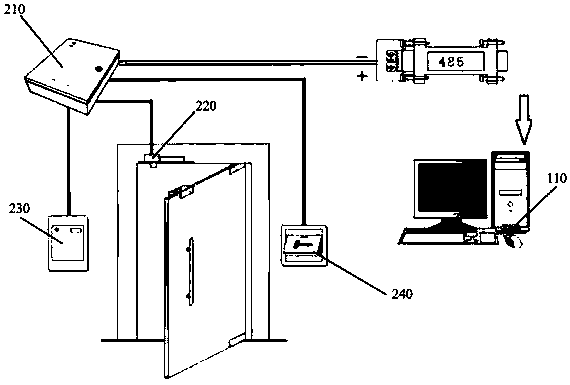

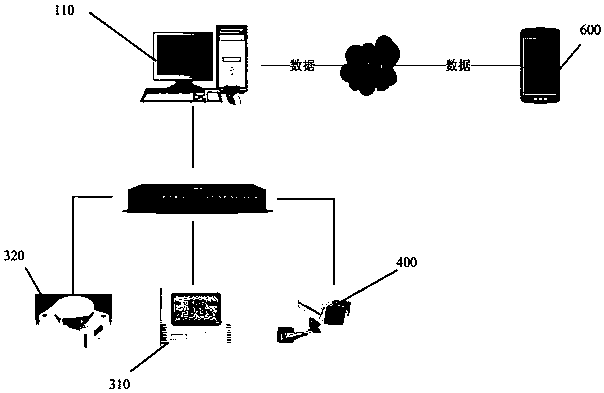

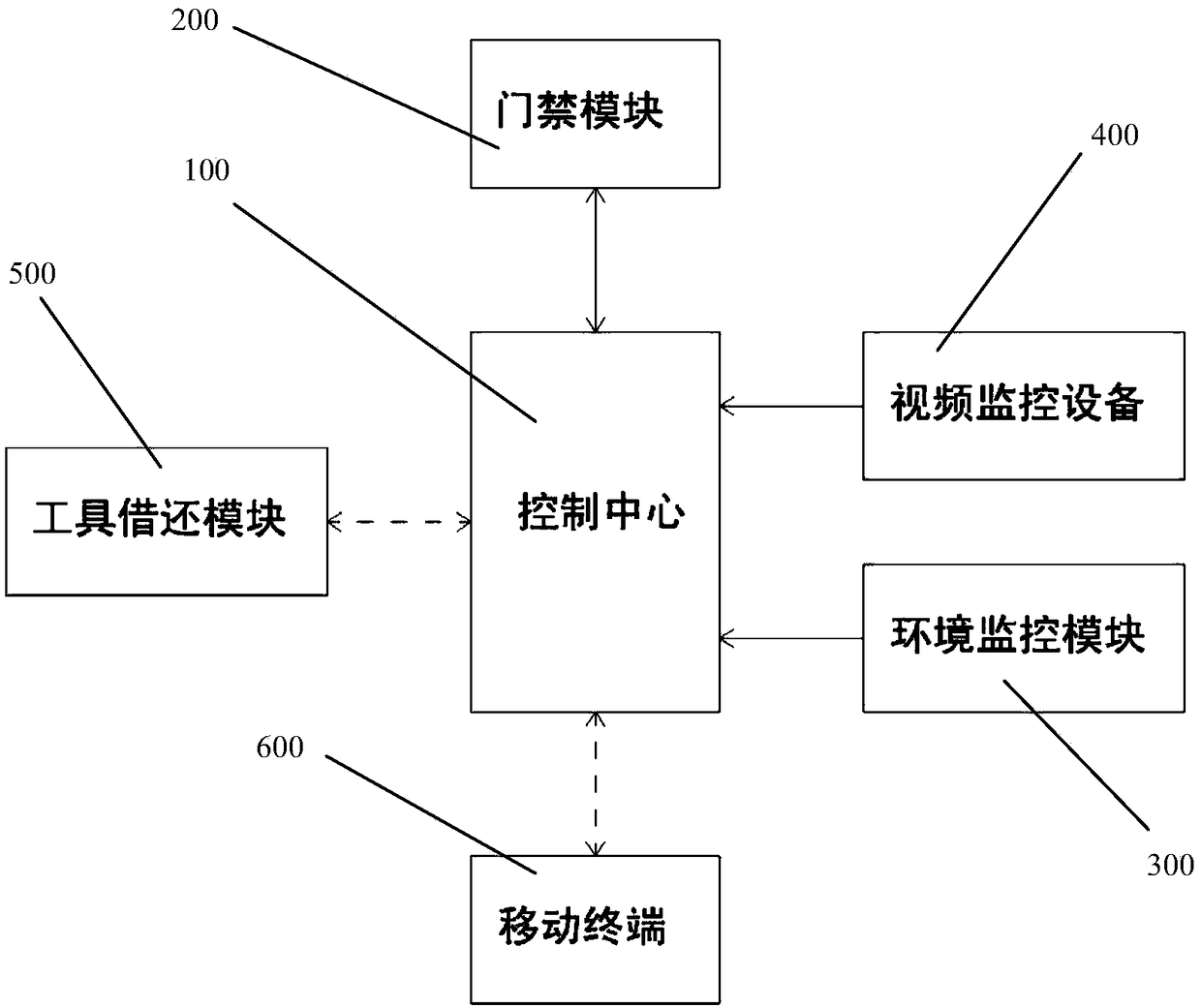

[0029] Examples, see figure 1 As shown, a kind of intelligent management platform for electric safety tools and appliances of the present invention includes a control center 100, an access control module 200, an environment monitoring module 300, a video monitoring device 400, a tool lending module 500 and a mobile terminal 600; The center 100 communicates with the access control module 200 and can receive, store and verify the door opening request of the access control module 200, and when the verification is correct, send the door opening instruction to the access control module 200; the control center 100 communication connection is installed in The environmental monitoring module 300 in the warehouse can also receive and store temperature and humidity data and smoke data. The control center 100 is connected to the video monitoring equipment 400 installed in the warehouse and can receive and store video information. The control center 100 is connected to The mobile terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com