Flying fork device

A technology of flying fork and spindle, applied in the direction of coil manufacturing, etc., can solve the problems of easy wire breakage and low winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

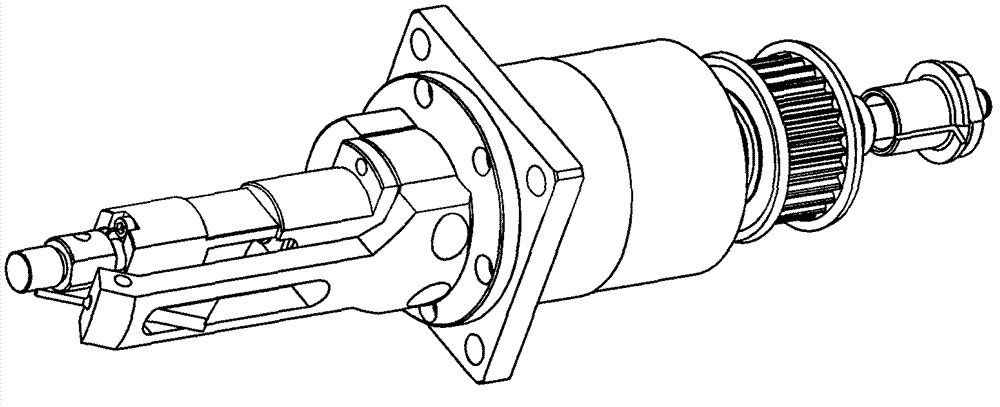

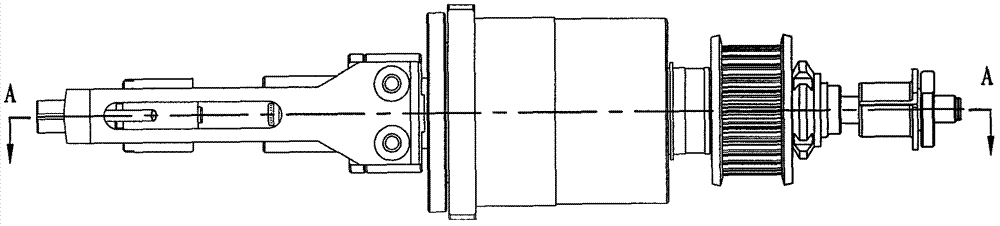

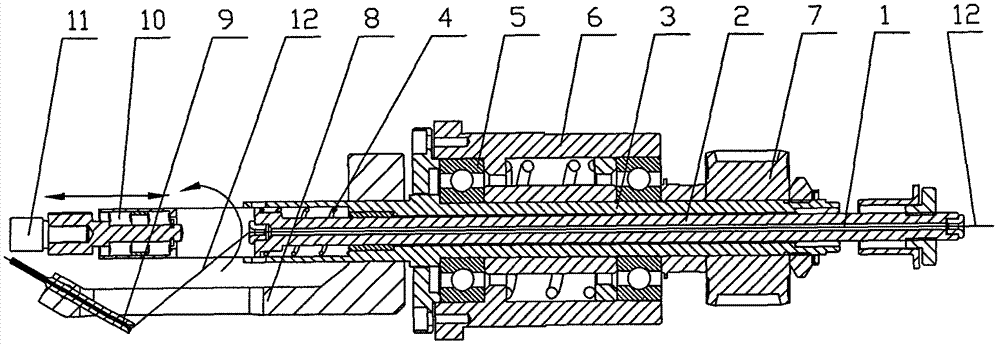

[0013] Figure 1 to Figure 3 It is a schematic diagram of the structure of the flying insertion device. It can be seen from the figure that it includes a fly fork mandrel 2 with a through hole 1 in the center. 3, the fly-fork mandrel 2 can move back and forth in the fly-fork main shaft 3 as image 3 and Figure 4 As shown, the flying fork main shaft 3 is fixed in the flying fork main shaft seat 6 through the bearing 5, the rear portion of the flying fork main shaft 3 is fixed with a synchronous pulley 7, and the flying fork main shaft 3 is fixed with a belt that rotates with the flying fork main shaft 3. The flying fork arm 8 is fixed with a tubular winding finger 9 on the flying fork arm 8 . The front end of the flying fork mandrel 2 is fixed with a top core 11 that withstands the skeleton or jig through the front bearing 10 . The winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com