Four-degree-of-freedom multi-layer parallel lifting mechanism of clamp car

A degree of freedom, clamping car technology, applied in the direction of trucks, transport passenger cars, railway car body parts, etc., can solve the problems of not reducing the working pressure of the lifting cylinder, not suitable for super-heavy goods, not suitable for loading and unloading goods, etc. Convenience and flexibility, reducing impact and increasing the effect of working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

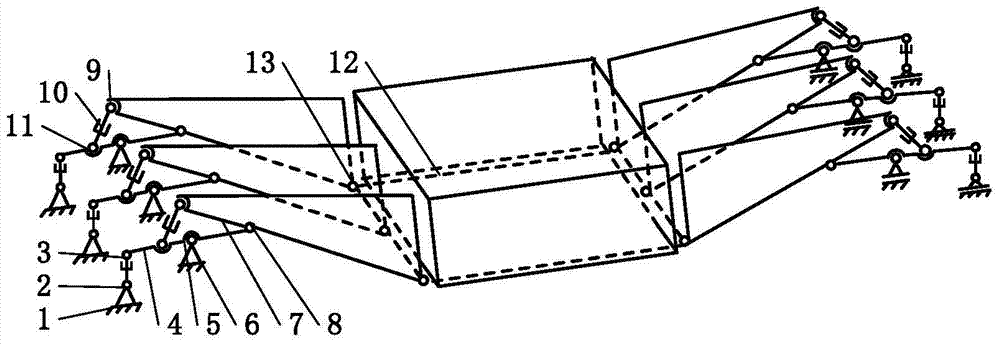

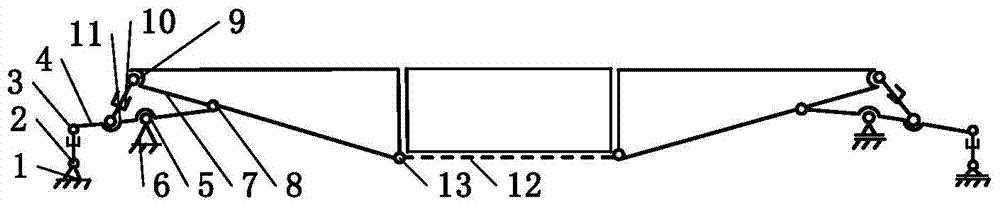

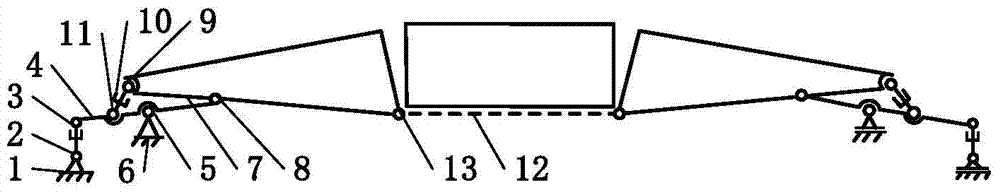

[0014] In the present invention figure 1 , figure 2 , image 3 with Figure 4 In the schematic diagram of , three bases A1 are placed on a horizontal plane, and the upper part of each base A is respectively connected to the fixed end of an adjusting cylinder 2, and the piston rod of the adjusting cylinder is hinged to one end of the support beam 4 through a hinge A3. The lower end in the middle of each supporting beam is connected with the upper end of the base B6 through a ball joint A5. The other end of each support beam is hinged with the lower end of the pincer beam 7 middle part by hinge B8. One end of the pincer beam is hinged with the upper part of the ball joint B9, the lower part of the ball joint B is connected with the piston rod of the lifting cylinder 10, and the fixed end of the lifting cylinder is hinged with the upper end of the support beam middle part through the ball joint C11. The other end of the pincer beam is respectively hinged with one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com