Method and system for tuning a gas turbine and gas turbine including such a system

A technology of gas turbines and turbines, which is applied in the direction of turbine/propulsion fuel delivery system, fuel control of turbine/propulsion device, charging system, etc., to achieve the effects of improving acceleration time, reducing the risk of stalling, and reducing the stall margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following description is made within the scope of the aircraft turbojet engine described in the present patent application. However, the invention may also be applied to other types of aviation gas turbines, such as helicopter turbines, or to industrial turbines.

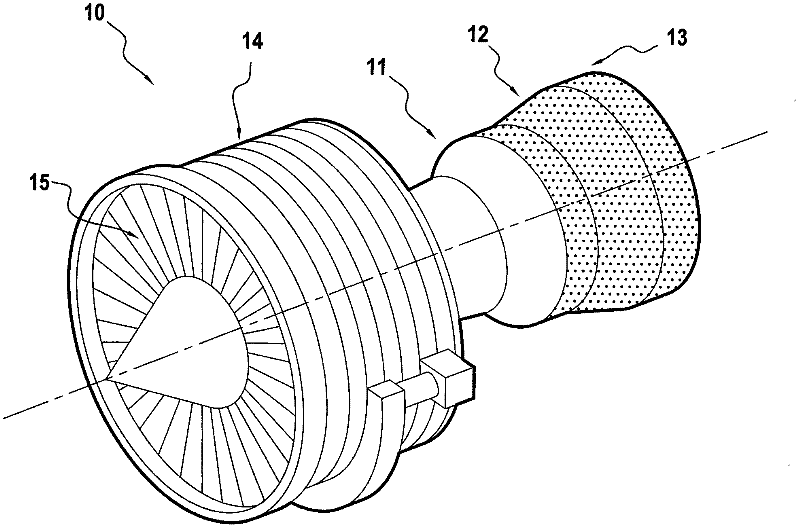

[0038] figure 1 A twin-shaft turbojet engine 10 for an aircraft is shown diagrammatically, comprising a combustion chamber 11 equipped with injectors, combustion gases in the combustion chamber 11 driving a high-pressure turbine 12 and a low-pressure turbine 13 . The high-pressure turbine 12 is connected by a high-pressure shaft to a high-pressure compressor 14 supplying compressed air to the combustion chamber 11 , while the low-pressure turbine 13 is connected by a low-pressure shaft to a fan 15 located at the inlet of the turbojet.

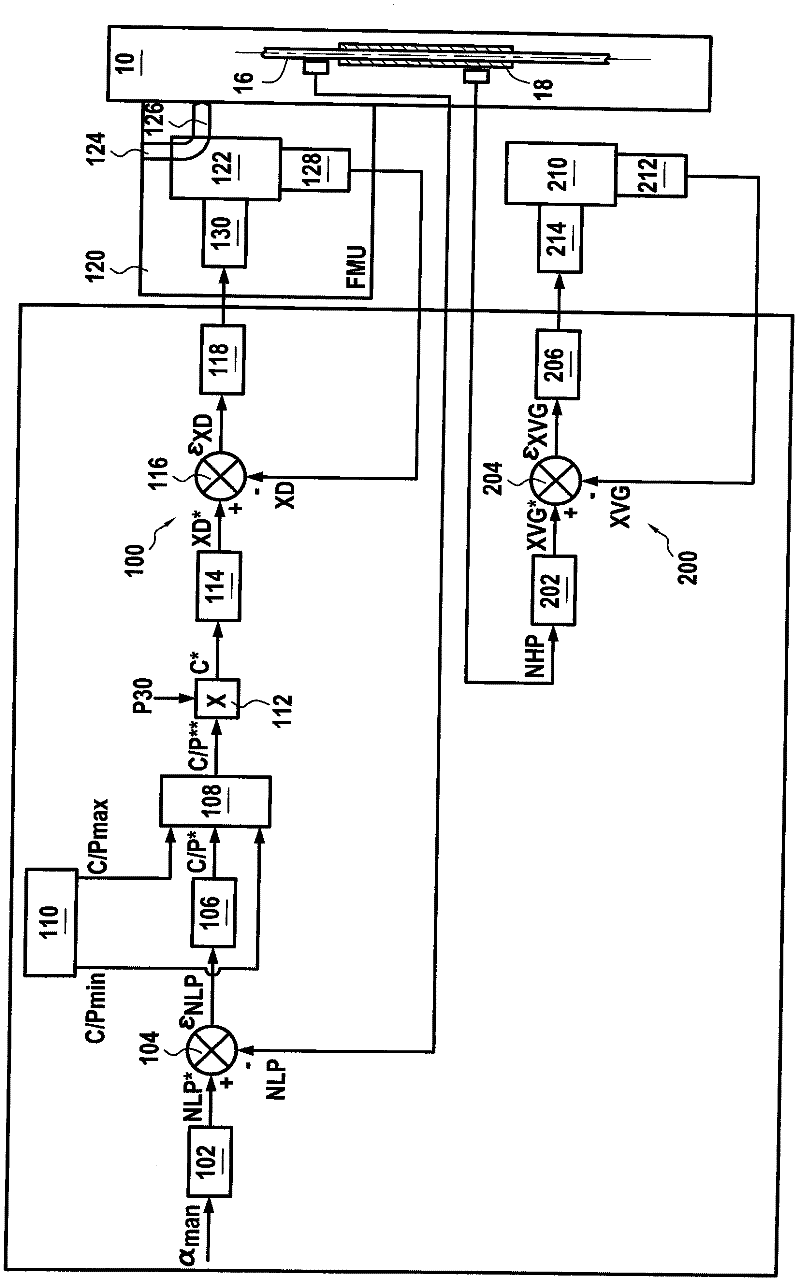

[0039] An embodiment of the control system according to the prior art is figure 2 shown.

[0040] Said control system comprises a main control loop 100 for forcing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com