Multi-blade fan

A blower and multi-blade technology, applied in mechanical equipment, engine manufacturing, machine/engine, etc., can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to this embodiment. In addition, the constituent elements of the present embodiment include a replaceable and easily replaceable structure while maintaining the identity of the invention. In addition, a plurality of modification examples described in this embodiment can be combined arbitrarily within the range that those skilled in the art can easily imagine.

[0029] [Multi-blade blower]

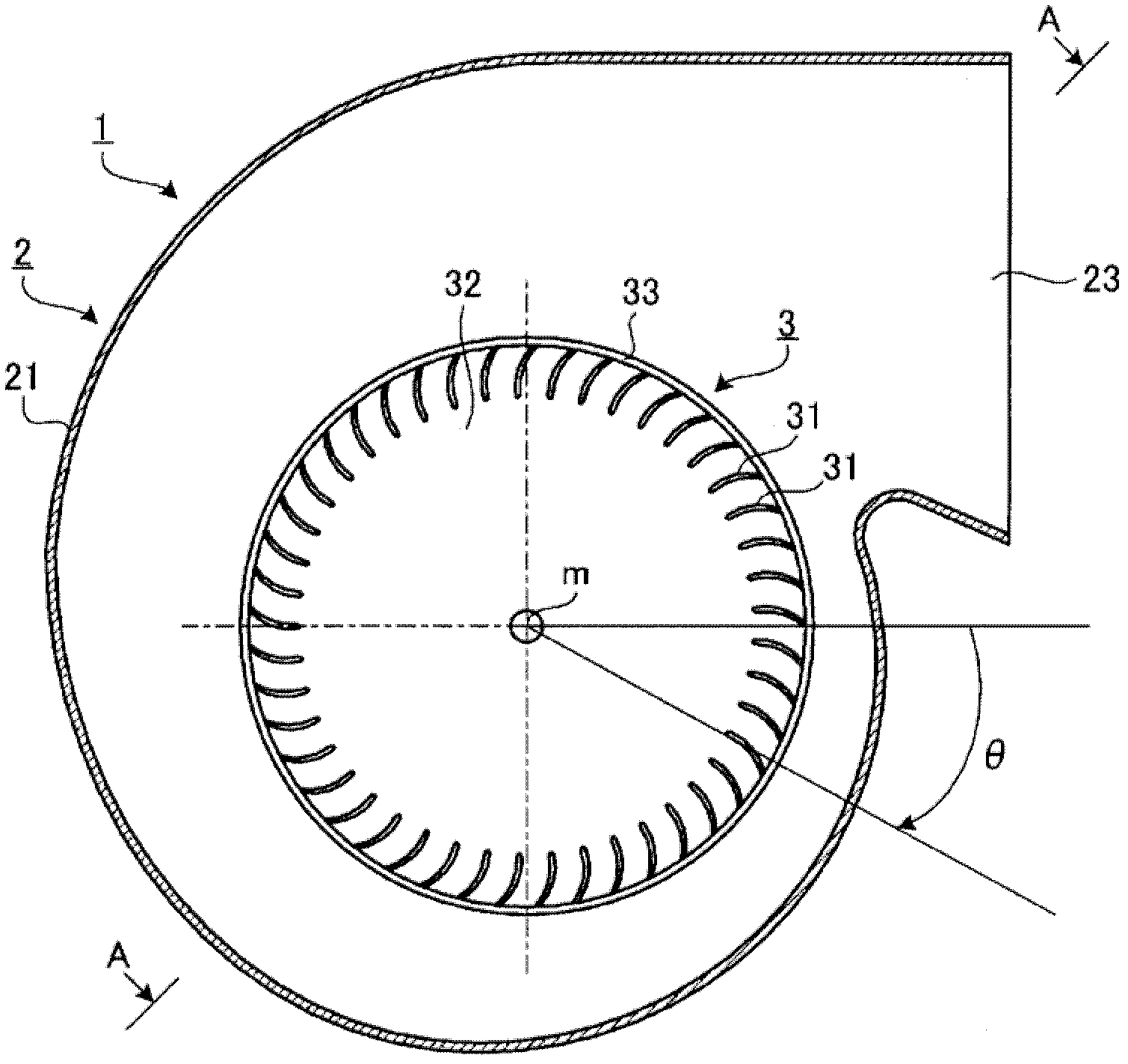

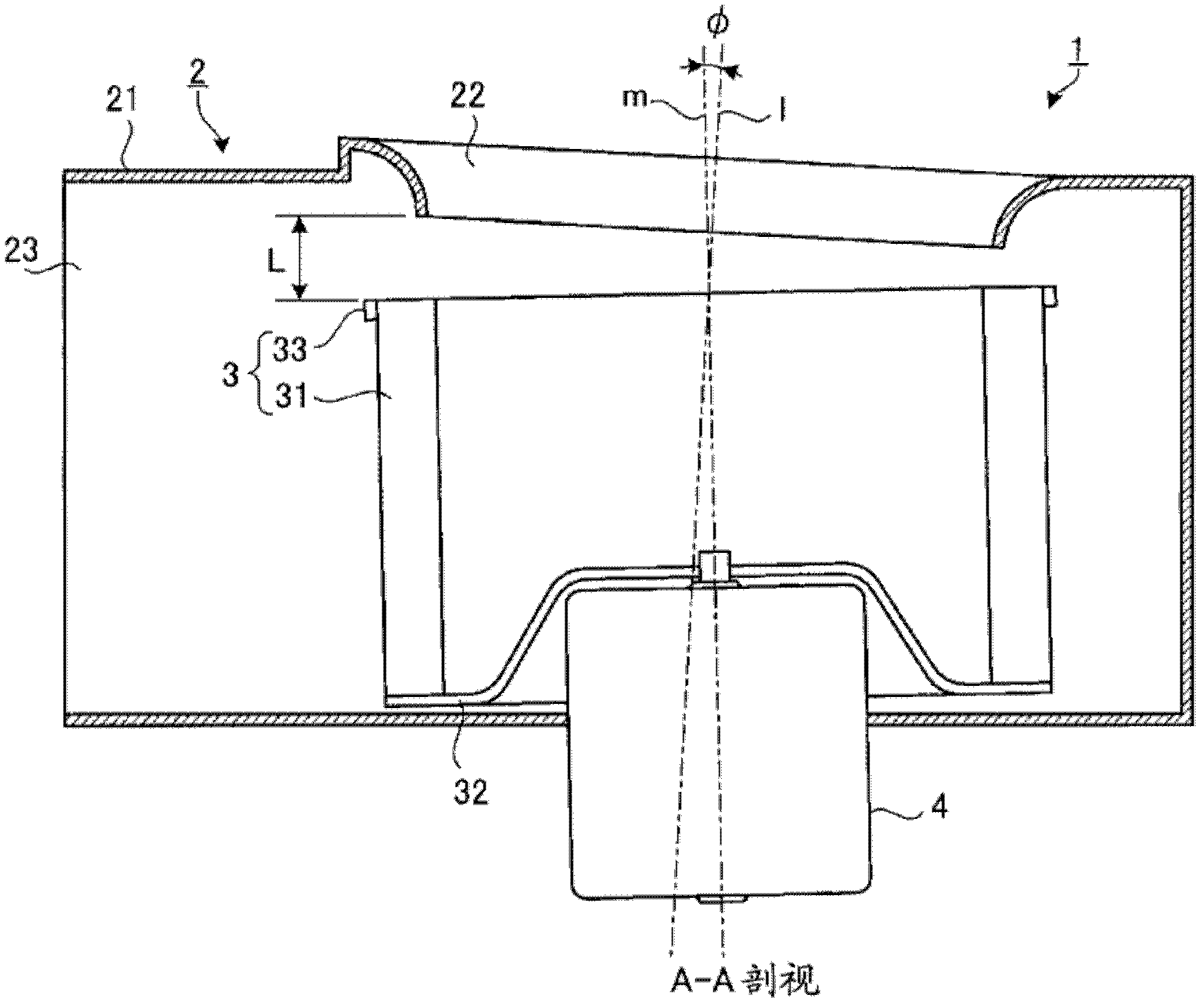

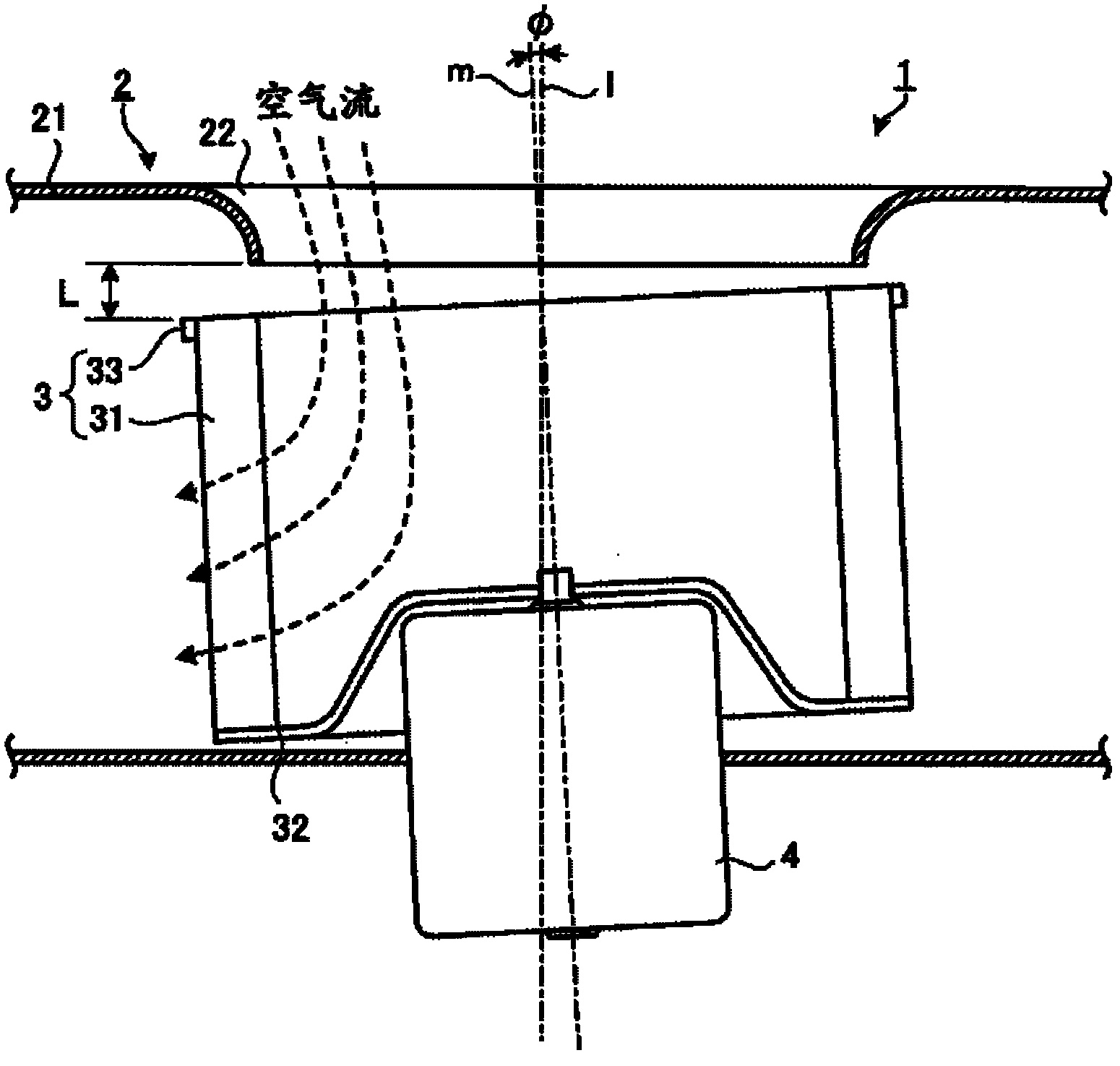

[0030] The multi-blade blower 1 is a blower having a multi-blade impeller (Sirocco fan), and is used, for example, in air conditioners, duct fans, ventilation fans, and the like. In addition, the multi-blade blower 1 may be a one-side suction type or a two-side suction type. In this embodiment, as an example, the multi-blade blower 1 adopting a one-side suction type will be described.

[0031] The multi-blade blower 1 has a housing 2, an impell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com