Method and device for forming U-shaped elastic knot by cold pressing

A cold forming and elastic technology, which is applied in the field of metal processing methods and devices, can solve the problems of manpower and equipment, a lot of time for repair, and long manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

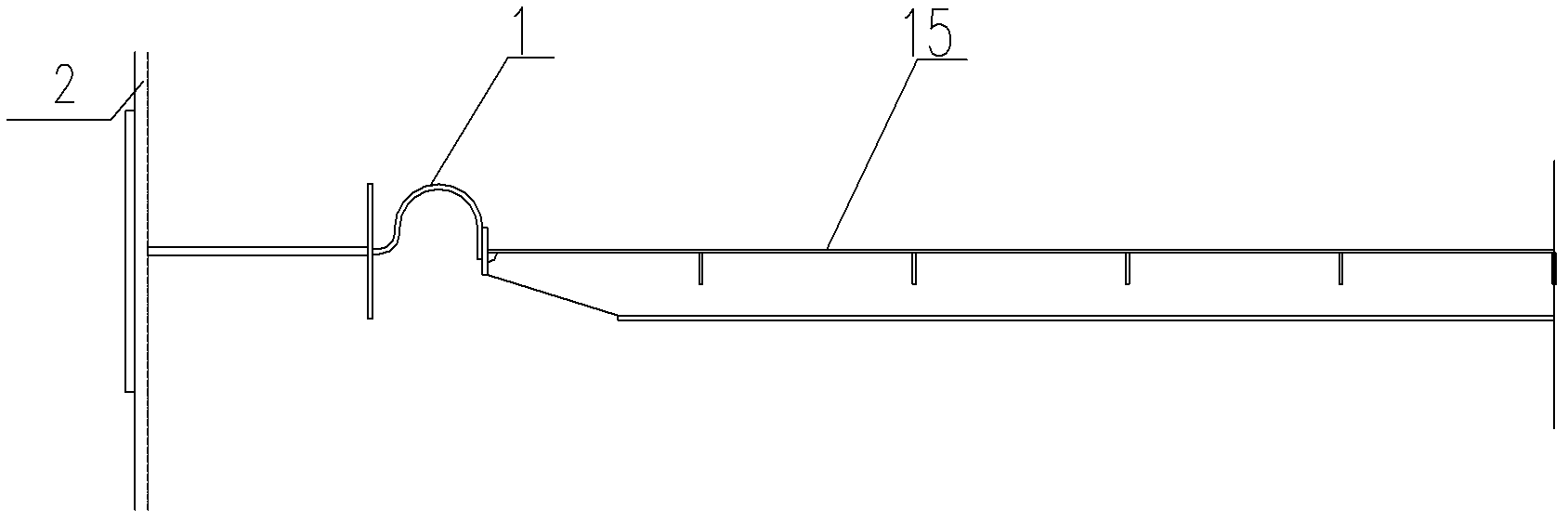

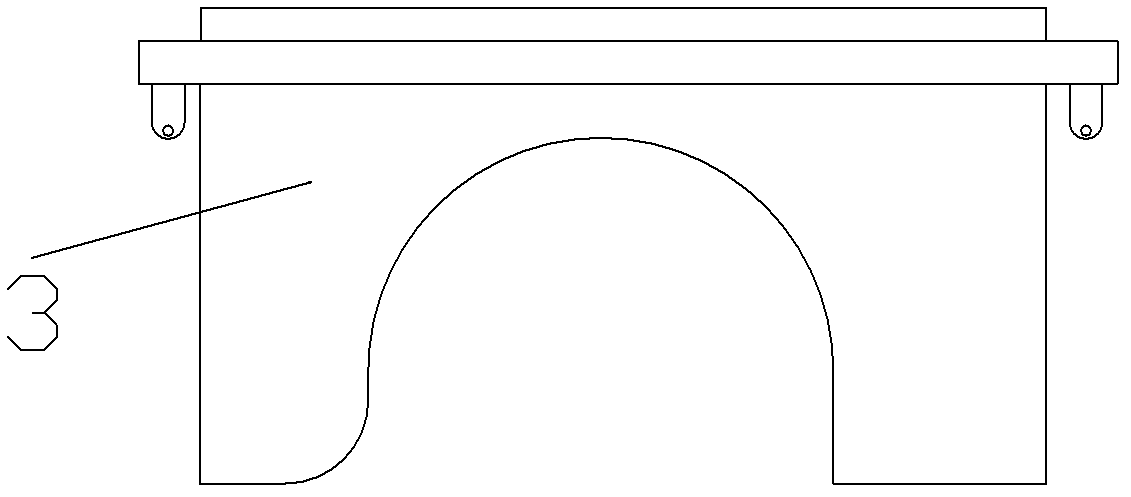

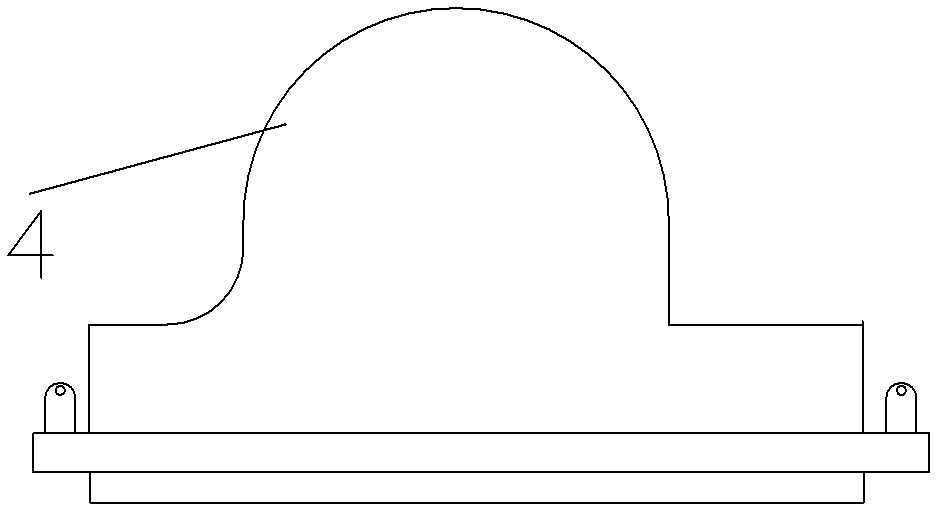

[0037] For a better understanding of the present invention, below in conjunction with the attached Figure 2-9 And embodiment the present invention is described further.

[0038] The U-shaped elastic knot cold-press forming method and device adopts a press to apply pressure to a pressing mold and press the elastic knot once to form it.

[0039] Such as Figure 2-7 As shown, the pressing mold is pressed by a press and mainly includes an upper mold 3 and a lower mold 4; the upper mold 3 is a portal structure with an arch-shaped recess in the middle; The arch-shaped recesses of the upper mold are matched with each other; the upper mold 3 is formed by inserting the upper mold bottom plate 5 and a plurality of upper mold ribs 6, and the lower mold 4 is formed by inserting the lower mold bottom plate 10 and a plurality of lower mold ribs 14; It includes a positioning plate 17 arranged on one side of the upper and lower molds 3 and 4, and the height of the positioning plate 17 is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com