Single crystal clamp for loop wire and single wire cutting machine and use method

A cutting machine and single crystal technology, which is used in the manufacture of tools, fine work devices, work accessories, etc., can solve the problems of hand-holding being easily caught, reducing work efficiency, increasing labor costs, etc. Risks, eliminate potential safety hazards, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

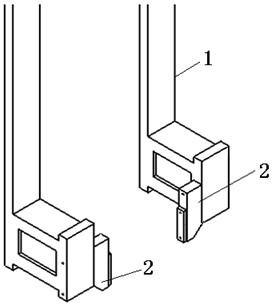

[0021] like figure 1 As shown, a single crystal clamp for circular wire and single wire cutting machine includes cutting machine clamp arm 1 and single crystal clamp. The single crystal clamp is composed of two sets of single clamps 2. Plate II 2-2 constitutes.

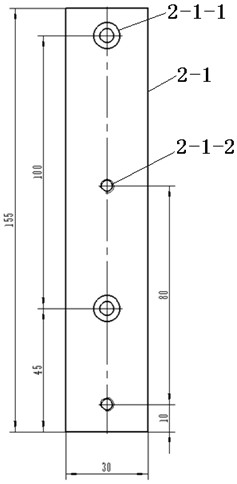

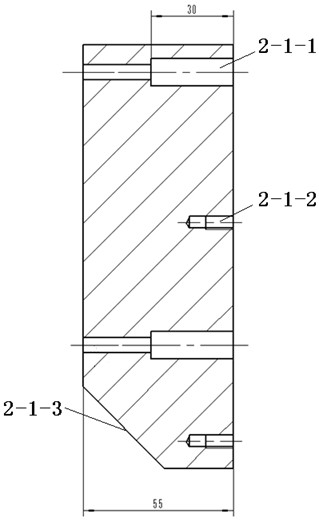

[0022] like figure 2 , image 3 As shown, the reinforcement plate I2-1 is a cuboid, and two counterbores I2-1-1 communicating with the back are arranged at intervals on the main surface of the reinforcement plate I2-1, and between the two counterbores I2-1-1 A blind hole 2-1-2 with an internal thread is respectively provided under the sink hole I2-1-1, and a slope 2-1-3 is formed between the bottom surface and the back of the support plate I2-1.

[0023] like Figure 4 , Figure 5 As shown, the reinforcing plate II2-2 is a cuboid, and two counterbores II2-2-1 communicating with the back are provided at intervals on the main surface of the reinforcing plate II2-2.

[0024] Fix a single crystal fixture on the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com