Disposable forming die for a plurality of bosses at end part

A boss and mold technology, applied in the field of mold preparation, can solve the problems of restricting product production efficiency, production quality, time-consuming precision, etc., and achieve the effects of high production and use efficiency, improved yield rate, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

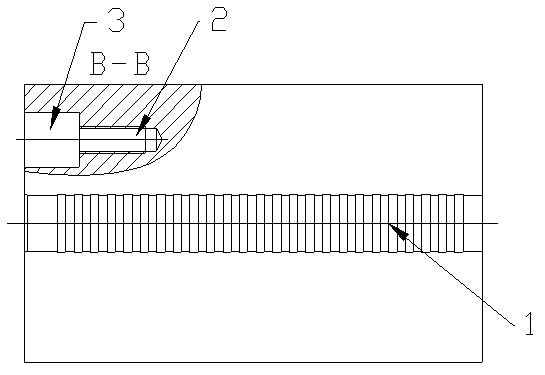

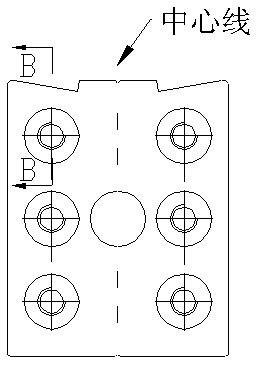

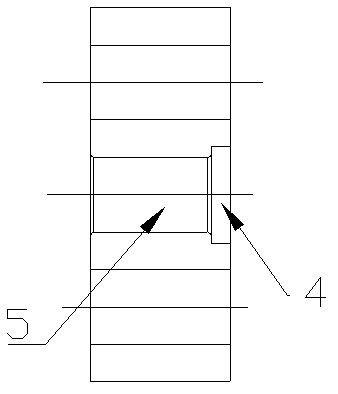

[0022] Below with the preparation of 3 boss steel pipes as example, the present invention is described in detail:

[0023] refer to Figure 4a , the multi-boss forming mold is composed of multiple clamping dies and the first clamping die A, the second clamping die B and the third clamping die C Figure 6 The punch is combined, the clamping die A, the clamping die B and the clamping die C are each one of the upper and lower clamping dies which are symmetrical to the center line, and the clamping die A, the clamping die B and the clamping die C use the inner hexagonal sinker Head screw E is used for connection, and return spring D is used in two adjacent clamping dies to ensure the gap between each clamping die. The first clamping mold A Figure 1a The clamping groove 1 in the clamping mold is used to clamp the product, and the clamping mold A is fixedly connected with the equipment, and the product cannot move in the clamping mold A. The second clamping mold B Figure 2a The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com