Hoisting tool for machining circular workpieces

A technology for hoisting tools and circular workpieces is applied in the field of mechanical processing, which can solve the problems of time-consuming and labor-intensive clamping operations, waste of production materials, and increased processing costs, and achieve the effects of saving metal materials, reducing processing costs, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

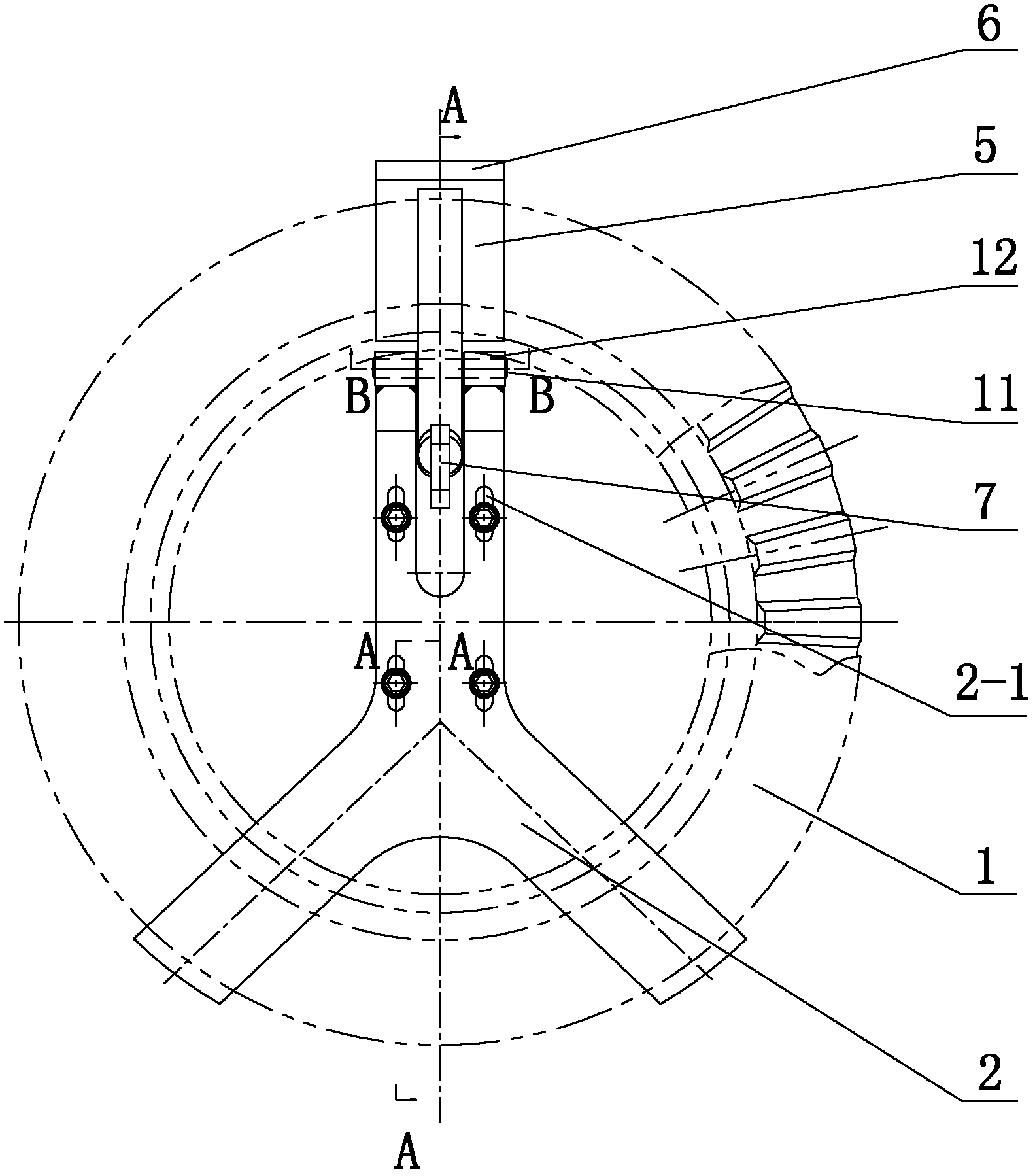

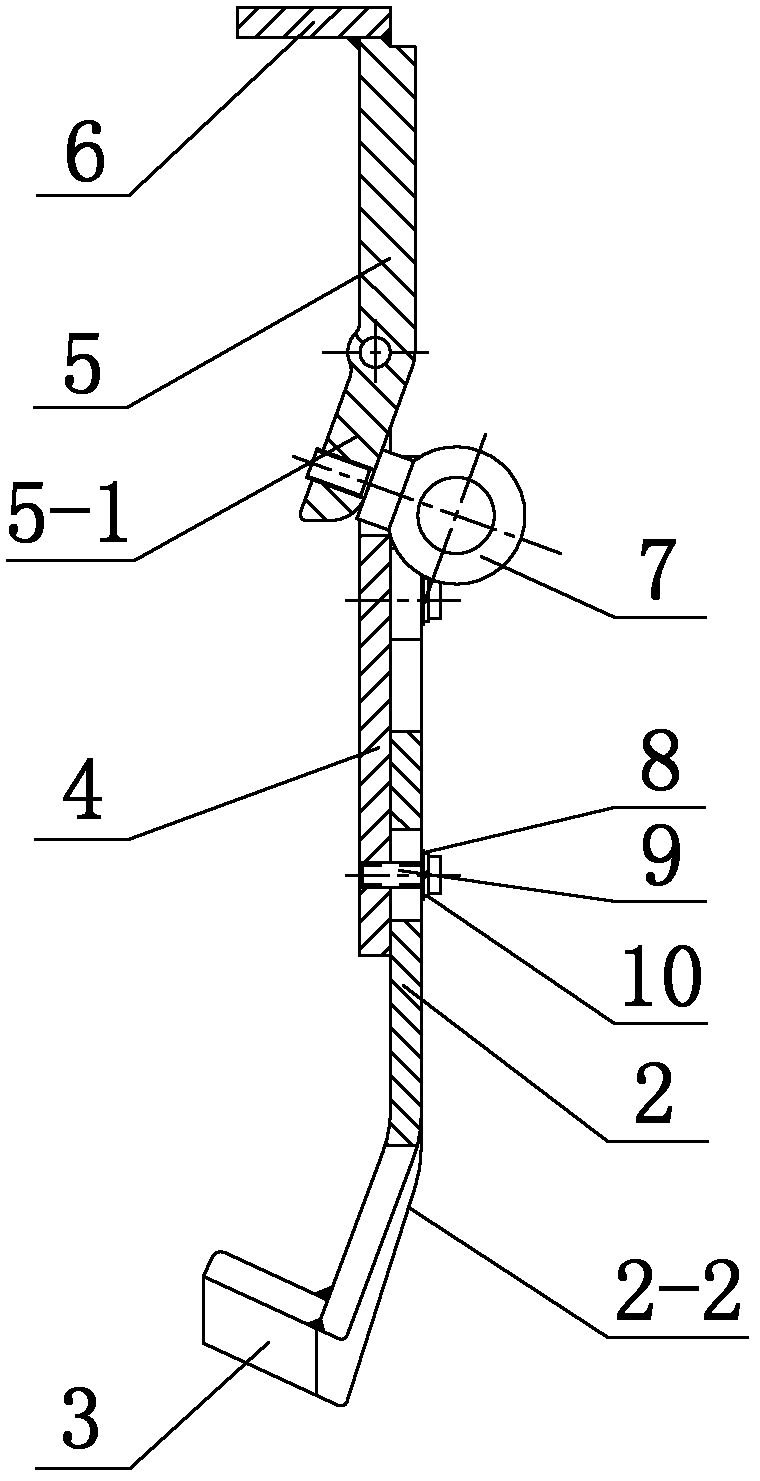

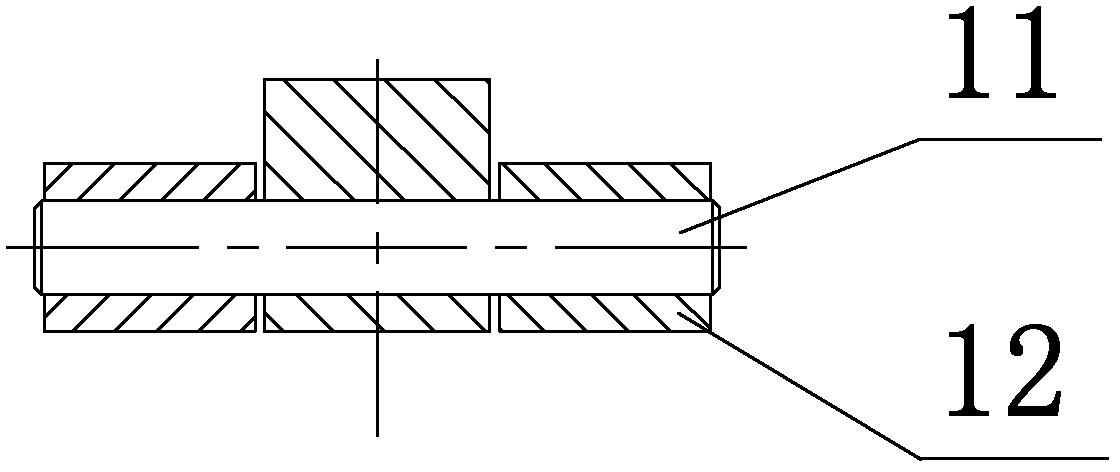

[0021] See Figure 1-Figure 3 , A hoisting tool for processing round workpieces, including an upper card body 5 and a lower card body 2 in an inverted Y shape. A U-shaped groove and an adjusting long hole 2-1 are formed on the upper part of the vertical arm of the lower card body, and the bottom surface of the vertical arm of the lower card body is connected by a fastener with a U-shaped groove 4-1 and a mounting hole. The supporting plate 4, the U-shaped groove 4-1 on the supporting plate 4 is matched with the U-shaped groove of the vertical arm of the lower card body, so as to leave a rotation space of the upper card body. In this embodiment, the bottom surface of the vertical arm of the lower card body is fixed to the support plate 4 through the screw 9, the spring wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com