Composite reinforced concrete corrosion-inhibiting agent and preparation method thereof

A technology of reinforced concrete and rust inhibitor, which is applied in the field of building materials, can solve the problems that the efficiency is not as obvious as that of the anode type, achieve good migration and diffusion performance, accelerate industry adjustment, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

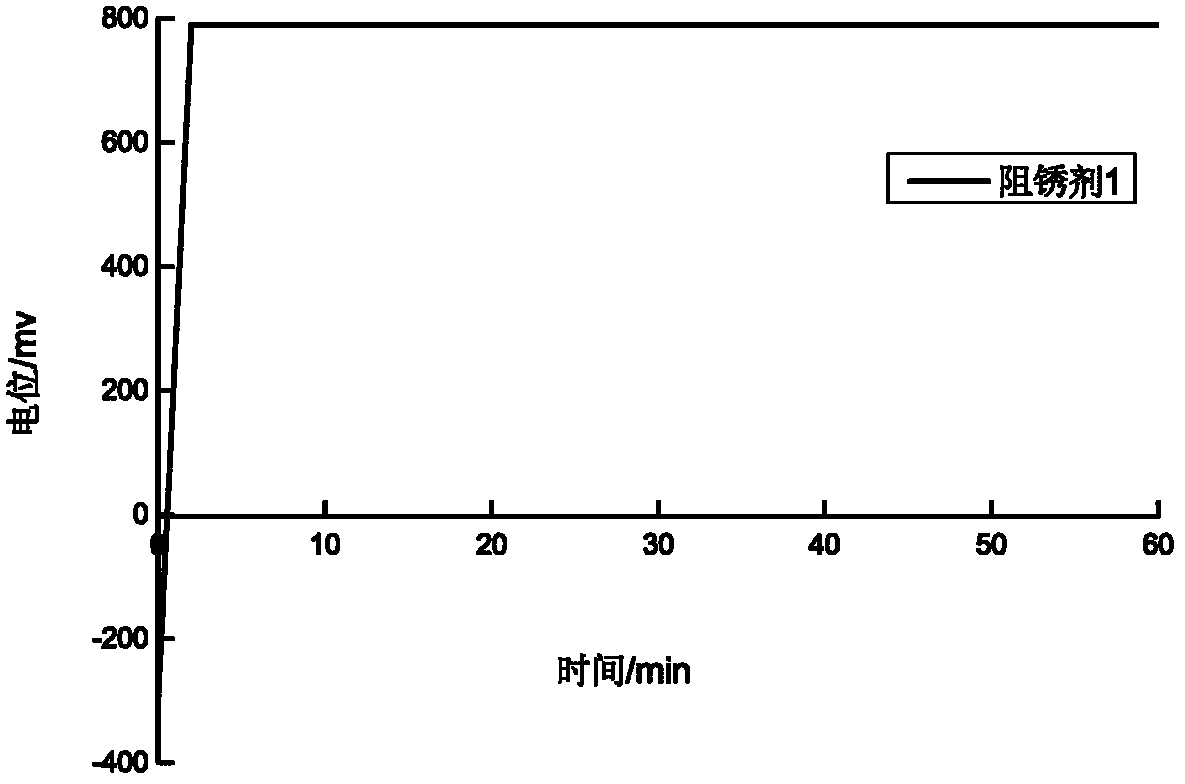

[0024] Take by weighing 2.5g zinc gluconate, 12.5g benzoic acid, 15.0g N-methyl monoethanolamine and 16.5g water, first benzoic acid is poured in the beaker, add zinc gluconate and N-methyl monoethanolamine, then at room temperature Slowly add water into the beaker while stirring continuously to prevent the reaction from being too violent. After adding water, continue stirring until the solution is clear, and cool the clear solution to room temperature.

[0025] Weigh 3.5 g of potassium monofluorophosphate, add it into the prepared clear solution, and stir until the potassium monofluorophosphate is completely dissolved to obtain a reinforced concrete rust inhibitor, marked as rust inhibitor 1.

Embodiment 2

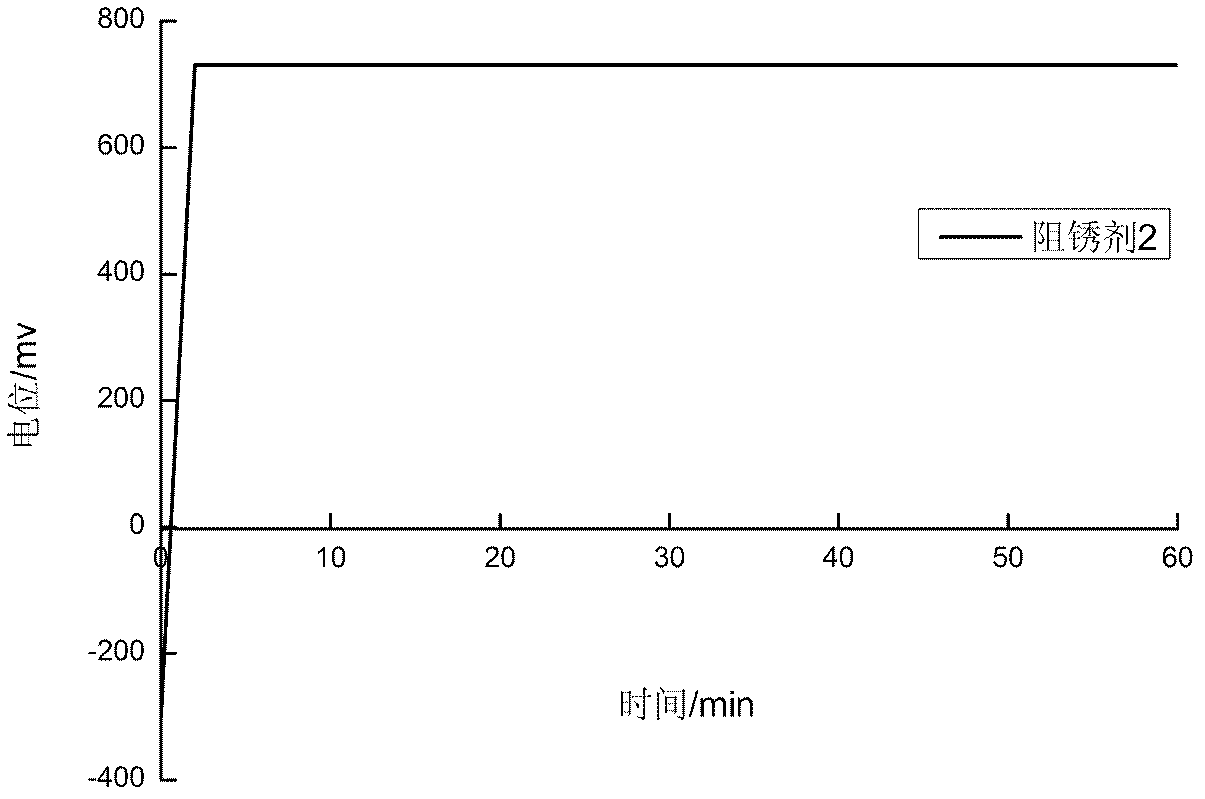

[0027] Weigh 3.5g zinc gluconate, 15.0g phosphoric acid, 12.5g triethanolamine and 15.0g water respectively, first pour phosphoric acid into a beaker, add zinc gluconate and triethanolamine, then slowly add water into the beaker at room temperature, while continuously Stir to prevent the reaction from being too violent, continue to stir until the solution is clear after adding water, and cool the clear solution to room temperature.

[0028] Weigh 5g of potassium monofluorophosphate, add it to the clear solution just prepared, and stir until the potassium monofluorophosphate is completely dissolved to obtain a reinforced concrete rust inhibitor, marked as rust inhibitor 2.

Embodiment 3

[0030] Take by weighing 1.5g zinc gluconate, 17.5g benzoic acid, 10g triethanolamine and 19.5g water, first benzoic acid is poured in the beaker, add zinc gluconate and triethanolamine, then water is slowly added in the beaker at normal temperature, simultaneously Stir continuously to prevent the reaction from being too violent. After adding water, continue to stir until the solution is clear, and cool the clear solution to room temperature.

[0031] Weigh 1.5 g of potassium monofluorophosphate, add it into the prepared clear solution, and stir until the potassium monofluorophosphate is completely dissolved to obtain a reinforced concrete rust inhibitor, marked as rust inhibitor 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com