Rotary testing machine

A technology of rotating test and operating platform, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., which can solve problems such as low efficiency, poor safety, backward control methods, etc., to reduce operating frequency and reduce Workload, to achieve the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

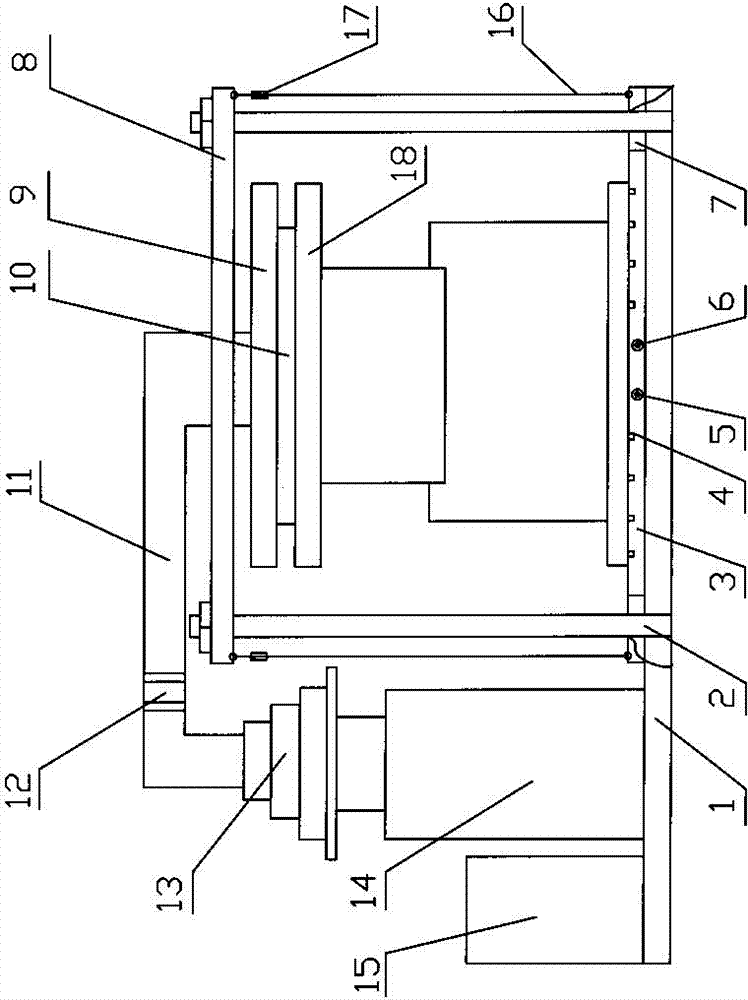

[0019] Such as figure 1 , it includes an installation base plate 1, four columns 2 and a motor 14 installed on the installation base plate, a liftable operating table 3 set on the lower part of the column, and an annular universal sealing groove 4 is concentrically distributed on the lifting operating table. The side of the middle part of the console is provided with a pressurized port 5 and a pressure test port 6, and a locking device 7 is provided on each column corresponding to the fitting part of the liftable console, and an upper plate 8 is set on the upper end of the column. A lifting device 16 is arranged between the liftable operating table, and a tension sensor 17 is arranged on the lifting device; the output end of the motor 14 is connected with a reducer 13, and the output end of the reducer is connected with a torque sensor 12, and the torque sensor passes through The drive train 11 is connected with the upper plate 8, and the lower end of the drive train passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com