Slip frequency type boiler pulse soot blower

A soot blowing device and slip technology, which is applied in the field of boiler soot blowing devices, can solve the problems of large amount of soot blowing at one time, threatening production, and existing space for energy saving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention is described in further detail below with reference to accompanying drawing:

[0008] Structural description of the present invention is as follows:

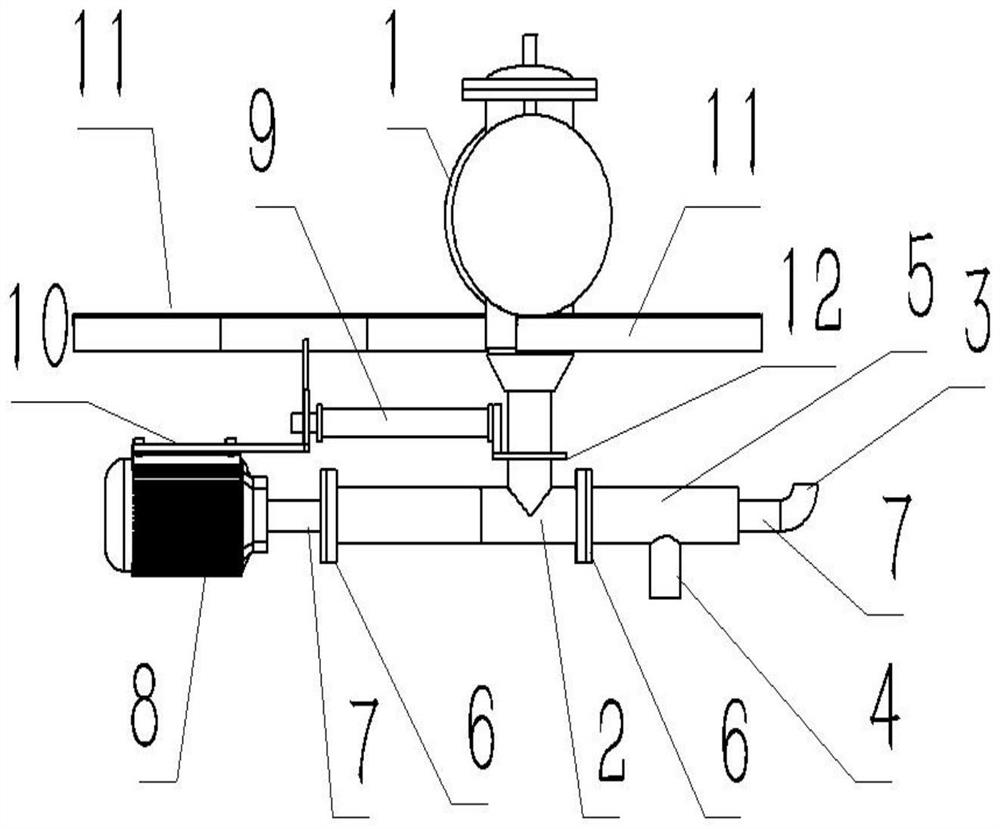

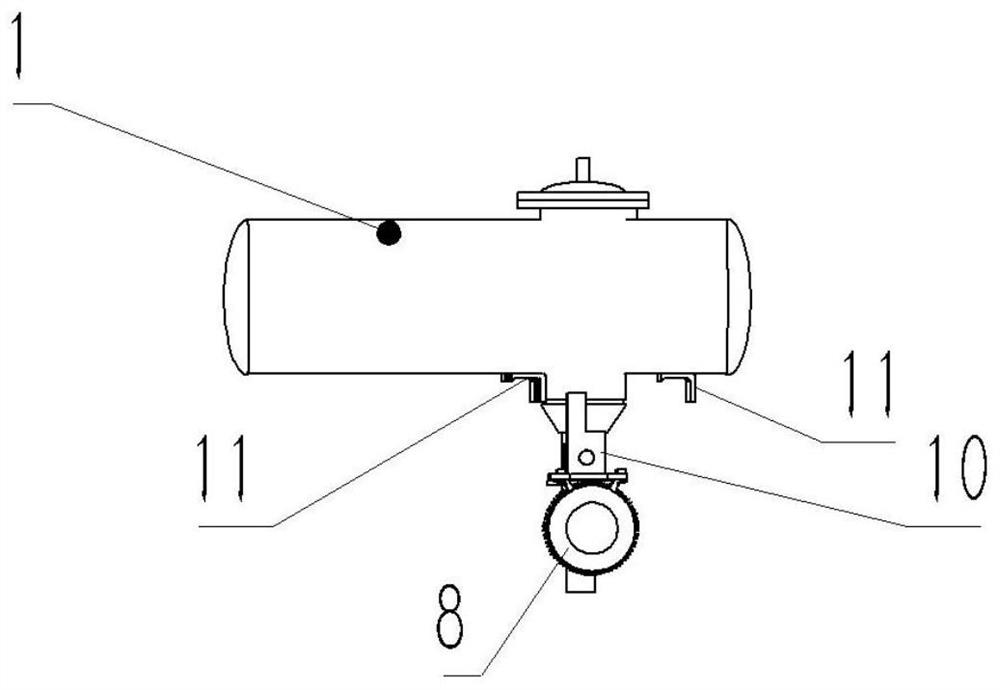

[0009] Refer to attached figure 1 , attached figure 2 As shown, a slip type boiler pulse soot blowing device mainly includes a pulse tank, a telescoping mechanism, a rotating mechanism, a spray explosion tube 7, etc., and a grid hole is provided in the middle of the spray explosion tube 7; the pulse tank Including pulse tank body 1, release valve 13, etc.; the telescopic mechanism includes cylinder 9, bracket two 12, bracket three 10, etc.; The squib 7 is installed in the casing 2 through the butt flange 6; wherein the casing 2 is a three-way pipe, the vertical inlet end of which is connected to the outlet of the release valve 13, and the bracket 2 12 is sleeved in its outer ring, Bracket 2 12 is used to fix the tail end of cylinder 9; the outlet end of described sleeve pipe 2 is connected with f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com