Visual testing device for liquid metal fluidity and testing method based on it

A liquid metal and testing device technology, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of low testing accuracy, invisible pouring speed and pouring temperature, etc., and achieve reliable control, visual recording, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

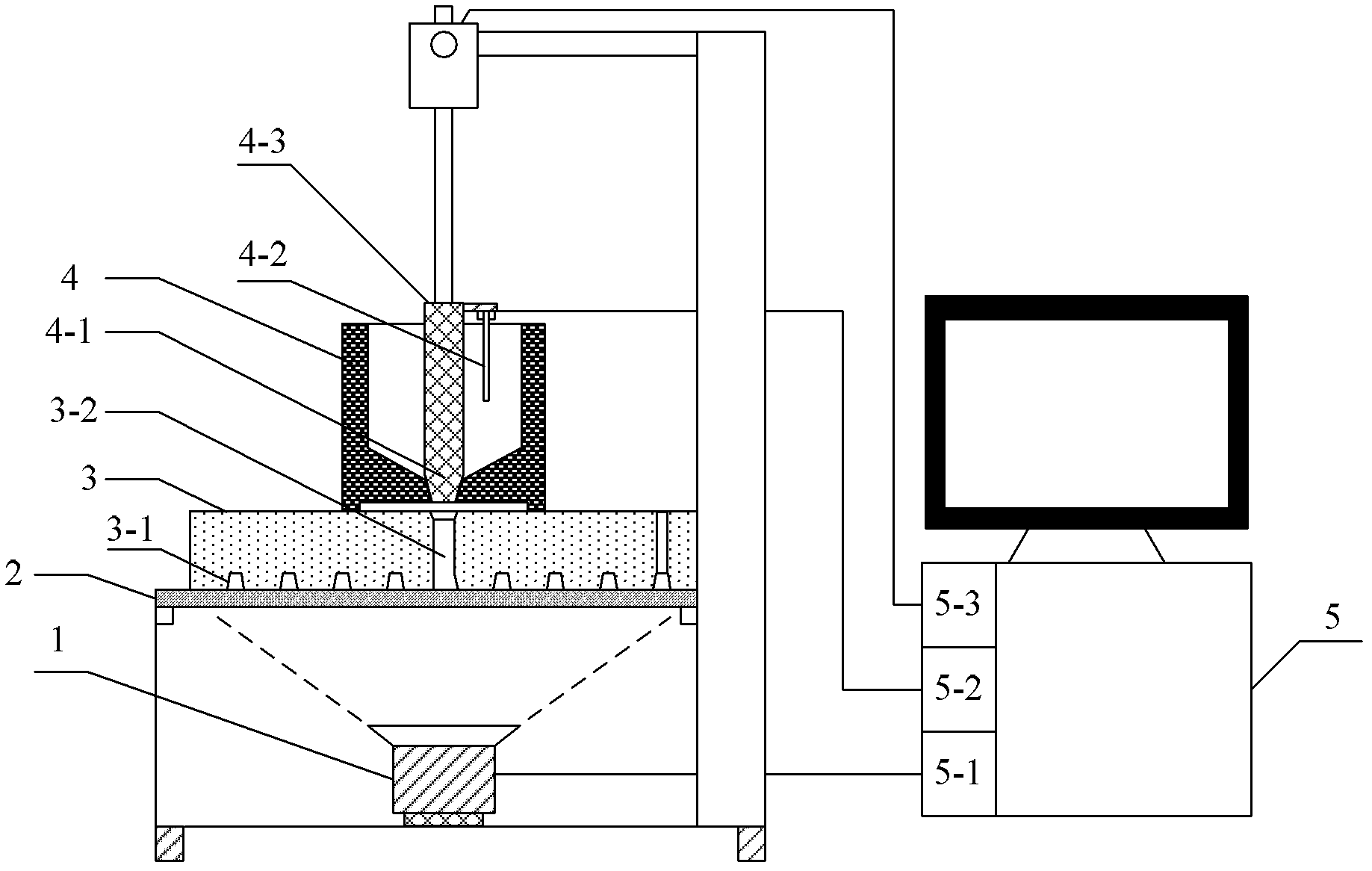

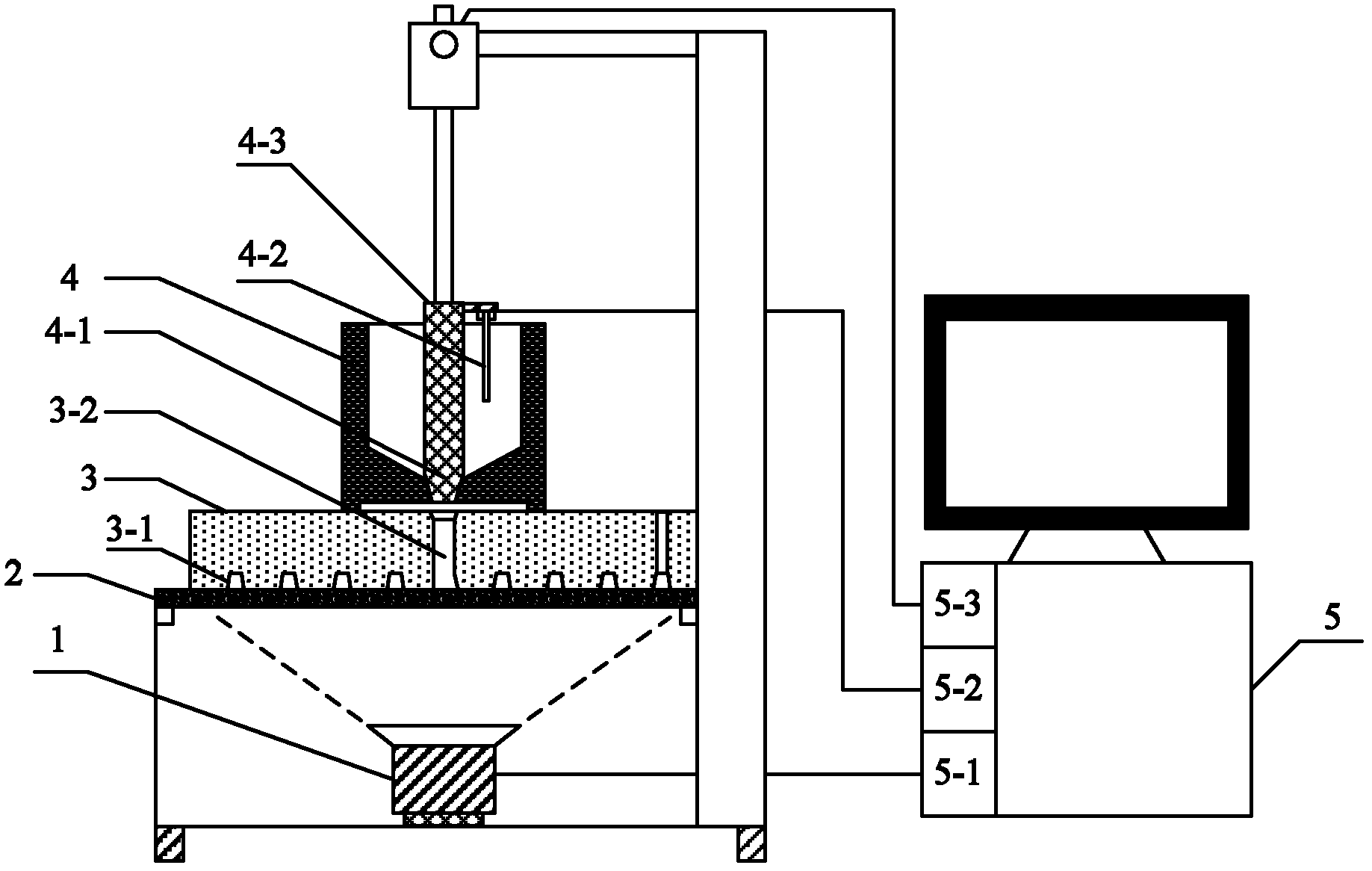

[0012] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, liquid metal fluidity visualization testing device, it comprises CCD camera 1, fluidity testing cavity 3-1, insulation sprue cup 4, temperature sensor 4-2 and computer 5, fluidity testing cavity 3 -1 is composed of a high temperature resistant quartz glass plate 2 and a clay sand upper box 3; the bottom surface of the clay sand upper box 3 is fixed on the high temperature resistant quartz glass plate 2; the CCD camera 1 is arranged under the high temperature resistant quartz glass plate 2, and the CCD The shooting surface of the camera 1 faces the high-temperature-resistant quartz glass plate 2, and the thermal insulation sprue cup 4 is placed above the clay sand upper box 3, and the gate at the bottom of the thermal insulation sprue cup 4 corresponds to the runner on the upper part of the clay sand upper box 3; the temperature sensor 4-2 is used for collecting the temperature of t...

specific Embodiment approach 2

[0013] Embodiment 2. The difference between this embodiment and the liquid metal fluidity visualization testing device described in Embodiment 1 is that it also includes a graphite stopper rod 4-3 and a lifting device, and the graphite stopper rod 4-3 is located at In the thermal insulation sprue cup 4, it is used to close the gate at the bottom of the thermal insulation sprue cup 4. One end of the graphite stopper rod 4-3 is connected to the lifting device, and the lifting device is used to drive the graphite stopper rod 4-3 to lift sports.

[0014] In this embodiment, a computer is used to control the lifting device to perform lifting motion.

[0015] Working principle: in the present invention, the high-temperature-resistant quartz glass plate 2 is used as the lower box, and the upper box of the fluidity sample is made of clay sand, and the upper box is combined on the lower box (high-temperature-resistant quartz glass plate), thereby forming Sample cavity for testing flui...

specific Embodiment approach 3

[0019] Embodiment 3. The difference between this embodiment and the liquid metal fluidity visualization test device described in Embodiment 1 or 2 is that the fluidity test cavity is a spiral cavity, a straight rod cavity or a serpentine cavity. One of the cavities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com