Secondary optical dodging mirror structure of light concentrating photovoltaic module

A technology of secondary optics and concentrating photovoltaics, applied in photovoltaic modules, concentrating mirrors, optics, etc., can solve the problems of insufficient chip effective area utilization, light leakage solar light spot, high chip temperature, etc., to achieve effective area utilization High, improve power generation efficiency, easy to dissipate heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

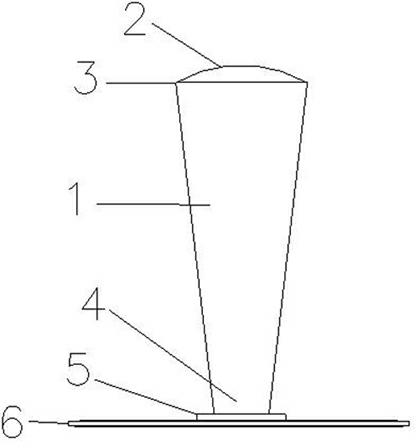

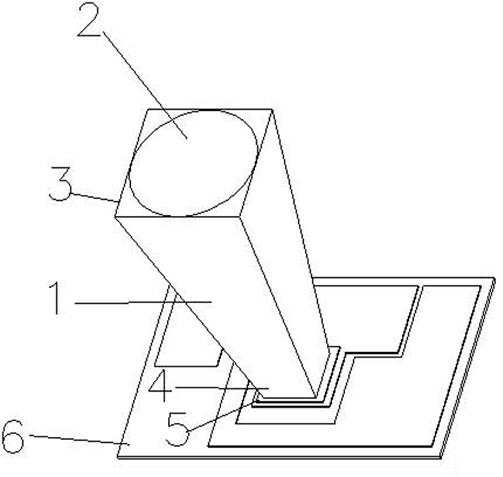

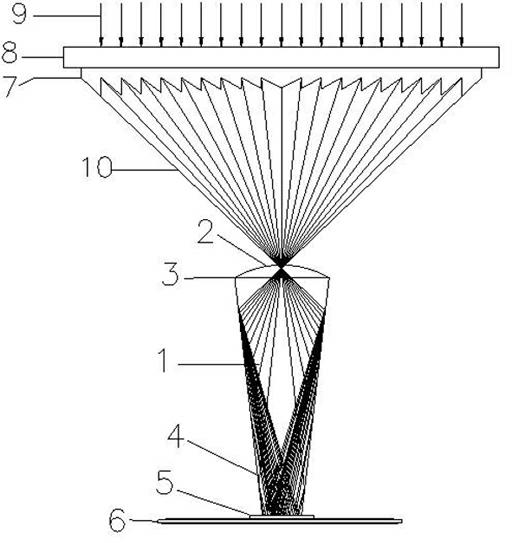

[0024] Such as figure 1 As shown, the secondary optical homogenizing mirror realized by the present invention is usually applied in a solar high-power concentrating photovoltaic power generation module. figure 2 As shown, the uniform light mirror 1 is a square conical structure with a large top and a small bottom. The upper conical surface 3 is large, and the lower conical surface 4 is small. The solar chip 5 is arranged at the bottom of the lower conical surface 4, and the solar chip 6 is again fixed on the substrate 6.

[0025] The cross-section of the uniform light mirror 1 is a square, which is convenient for light refraction; the diameter of the bottom of the hemispherical surface 2 covered by the upper conical surface 3 is consistent with the diameter length and width of the upper conical surface 3, so that the hemispherical body 2 can It is completely covered and fixed on the upper conical surface 3, and the size of the upper conical surface 3 is generally determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com