Plastic plug with short circuit ring function

A technology of short-circuit rings and blocking parts, which is applied to the parts, circuits, and contact parts of the connecting device, and can solve the problems of inability to realize short-circuiting of wiring harness connectors, poor versatility of wiring harnesses, and poor sealing of wiring harness connectors. Achieve the effects of reducing the number and management costs, protecting short-circuit terminals, and ensuring assembly consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

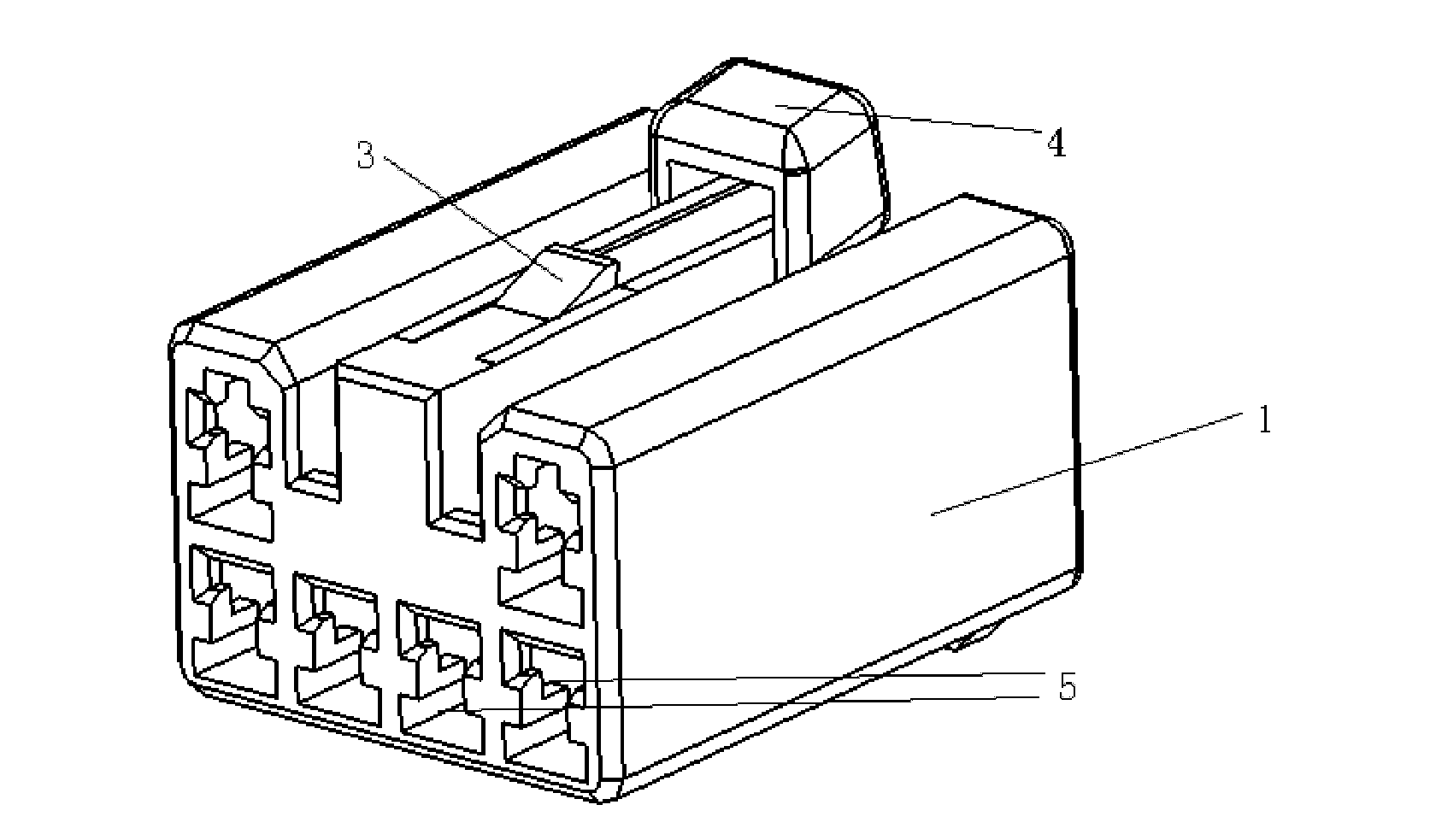

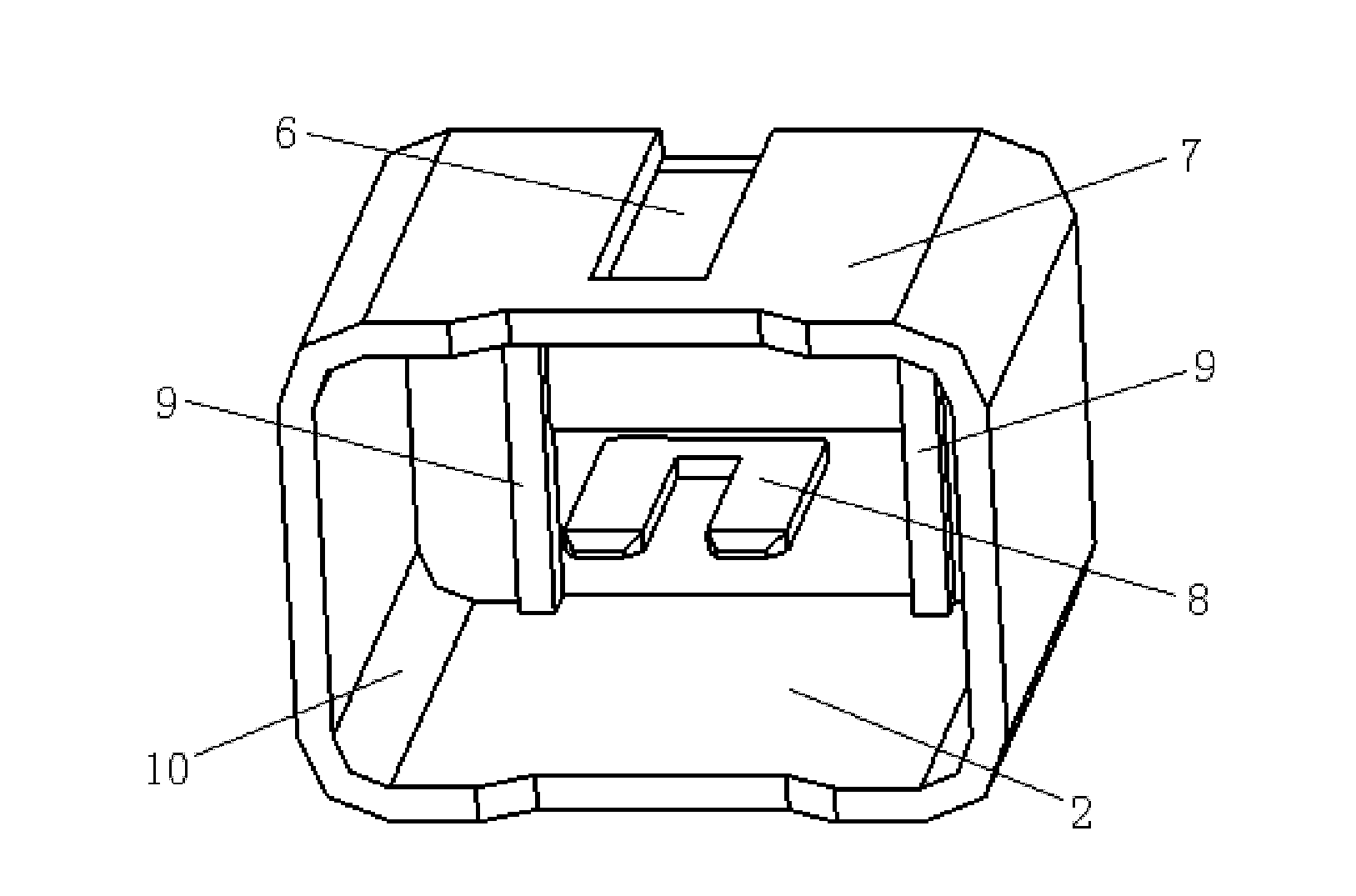

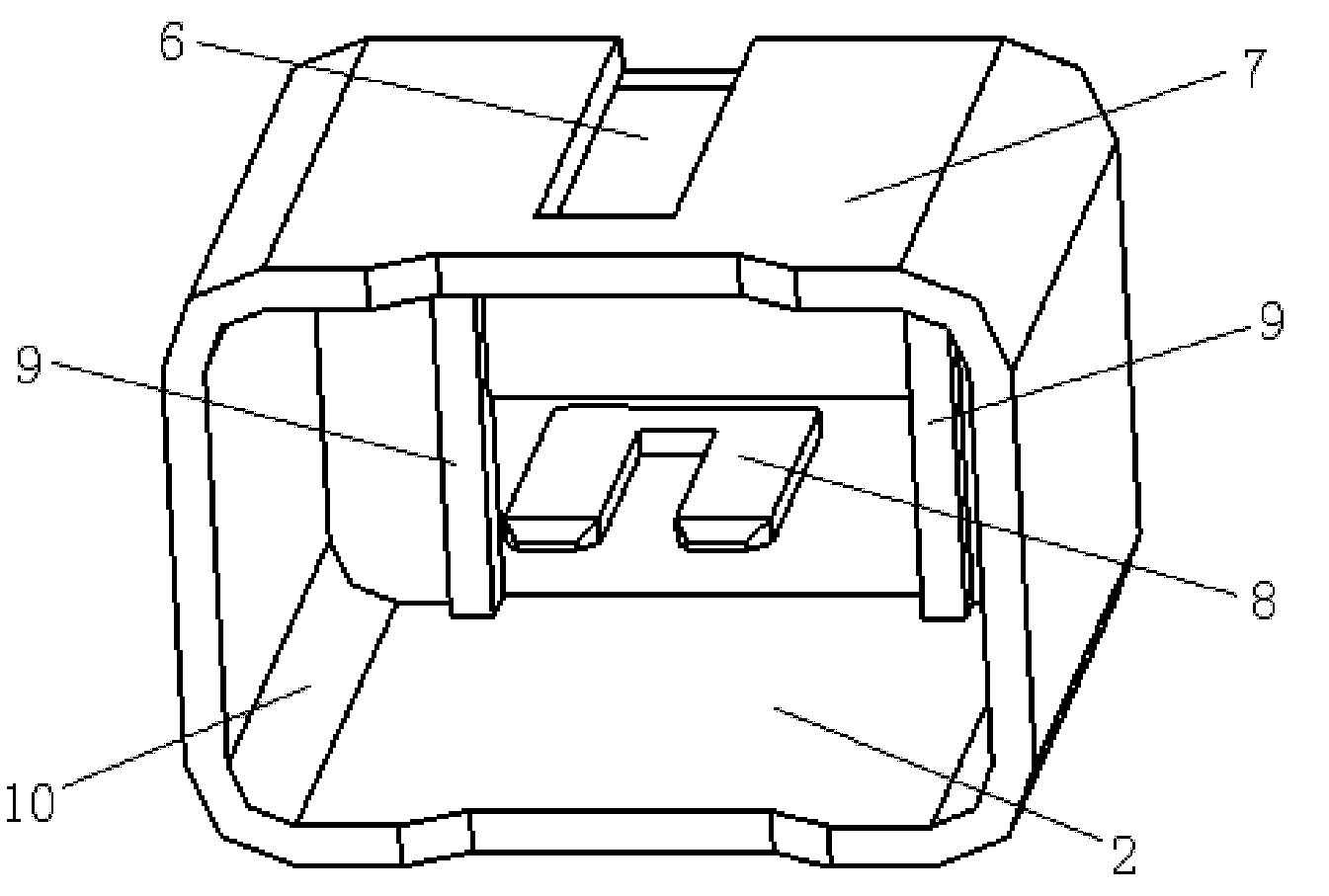

[0022] Embodiment 1, as figure 1 , figure 2 As shown, a plastic blocking piece with a short-circuit ring function includes a blocking piece body 7, which is a rectangular parallelepiped structure with one end open, and the shape of the blocking piece body 7 is adapted to the reserved wiring harness connector 1. The above-mentioned blocking member body 7 is provided with a short-circuit ring metal sheet 8 conducting through the two terminals 5 of the wire harness connector. The short-circuit ring metal sheet 8 can be a U-shaped structure. When in use, the plastic blocking piece 2 is inserted into the end of the wiring harness connector 1 . The short-circuit ring metal sheet 8 in the plastic blocking member 2 ensures the short-circuit conduction between the reserved wiring harness connector 1 that needs short-circuit conduction terminals 5 . Therefore, a common set of wiring harnesses can be used for different configurations, and the wiring harness connector 1 does not need ...

Embodiment 2

[0023] Embodiment 2. On the basis of the technical solution of Embodiment 1, a rectangular slot 6 is opened on the side of the plastic blocking member 2, and the size of the slot 6 is suitable for the locking and fixing structure 3 of the wiring harness connector 1. Matching, one end of the slot 6 extends to the sealing end surface of the plastic plug 2. The locking and fixing structure 3 of the reserved connector 1 is a triangular block structure, which is fixed with the slot 6 on the plastic plug 2 to prevent the plastic plug 2 from falling off during the movement. The reserved connector 1 is also provided with a press-loose locking and pulling-off structure 4, which facilitates the removal and insertion of the plastic plug 2 and provides convenience for future selection. The plastic plug 2 can be reused to save cost.

Embodiment 3

[0024] Embodiment 3. On the basis of the technical solution of Embodiment 1, the plastic blocking member 2 is provided with a limit structure 9 that is compatible with the end face of the wire harness connector 1, and the limit structure 9 is compatible with the wire harness connector. The elongated structure that matches the end faces of the 2 can well ensure that the plastic plug 2 is plugged in place, ensures the consistency of assembly, and can well protect the short-circuit terminal 5. In order to realize assembly more quickly and conveniently, an introduction surface 10 is provided on the inside of the plastic blocking member 2 to facilitate the extraction and insertion of the wire harness inserter 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com