Internal combustion engine

A technology for internal combustion engines and engines, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of unsuitable small volume, complicated rotating cylinder valves, difficult cost advantages, etc., achieve flexible design, improve sealing performance and heat performance, improved cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

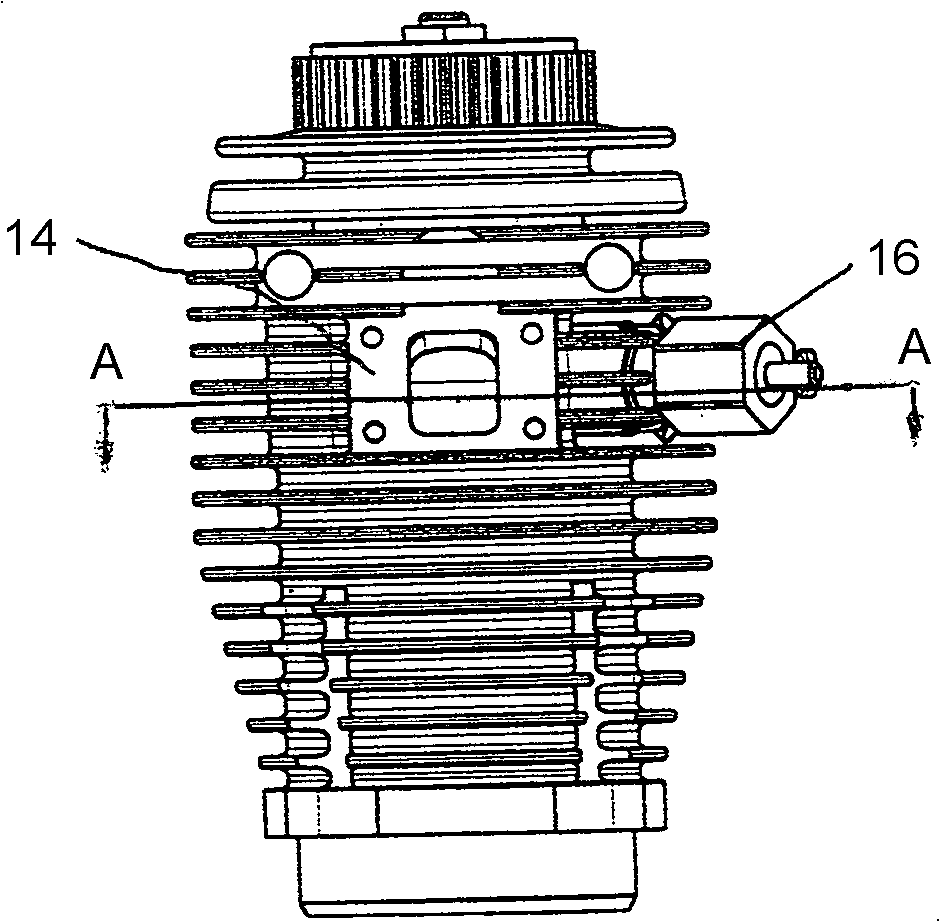

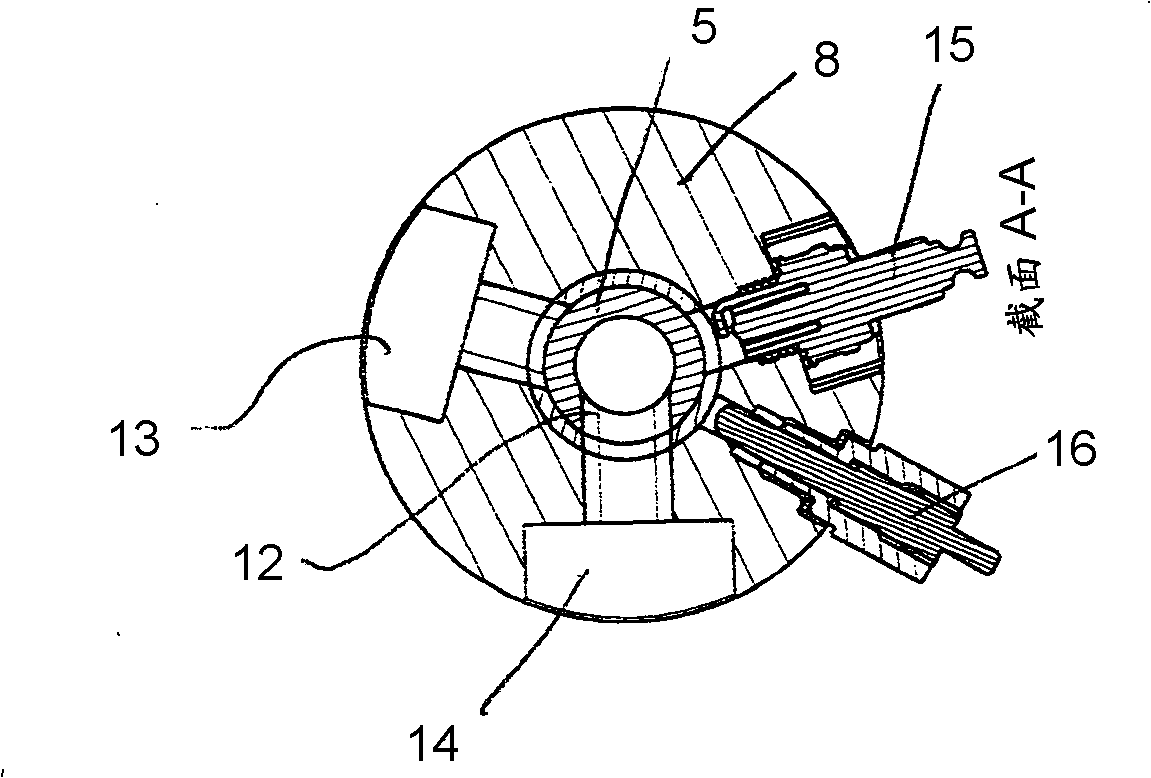

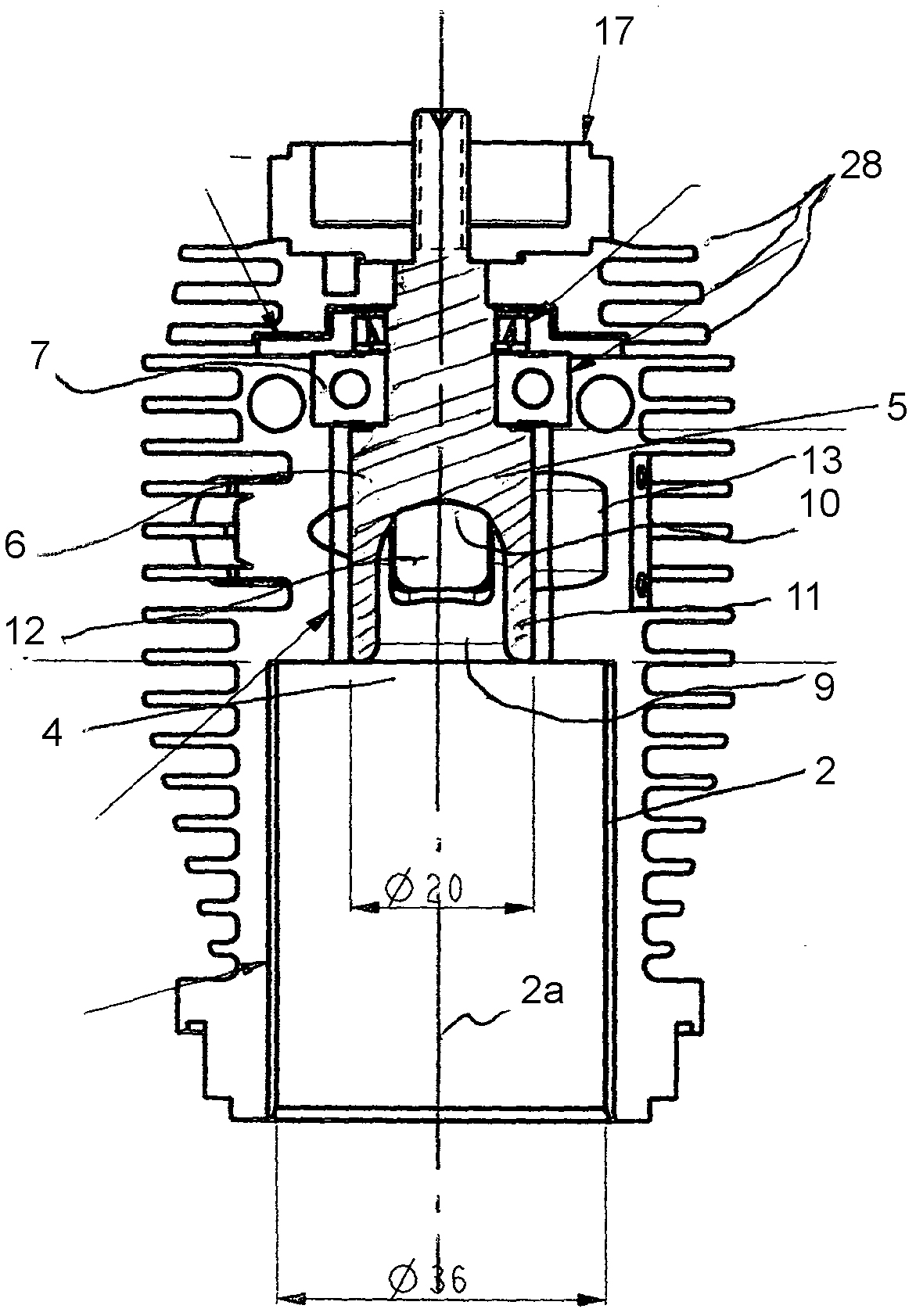

[0056] Referring to the attached drawings, figure 1 , 2 and 3 shows a single-cylinder air-cooled engine, Figure 5 and 6 A horizontally opposed two-cylinder engine is shown. Each cylinder 2 has a piston 1 ( Figure 5 and 6 ), the piston 1 is connected to the crankshaft 3 in a conventional manner for reciprocating movement within the cylinder 2. Especially as figure 2 As shown, the upper portion of the cylinder 2 is closed to form the combustion chamber 4 . like figure 2 The rotary valve 5 controls the flow of intake air into the combustion chamber 4 and the flow of exhaust air out of the combustion chamber 4 , as shown in cross section of . In this embodiment, the valve is rotatable about the axis 2a of the cylinder 2 .

[0057] The rotary valve comprises a first cylindrical part 6 mounted on a ball bearing 7 on the side of the valve 5 remote from the combustion chamber 4 for rotation in a hole in a valve sleeve 8 in which the The cylindrical portion 6 is a tight s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com