Chamfering die

A chamfering die and chamfering technology, applied in the field of cold stamping dies, can solve problems such as time-consuming product surface, scratches and burrs, and achieve the effects of improving production efficiency, precise dimensional processing, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

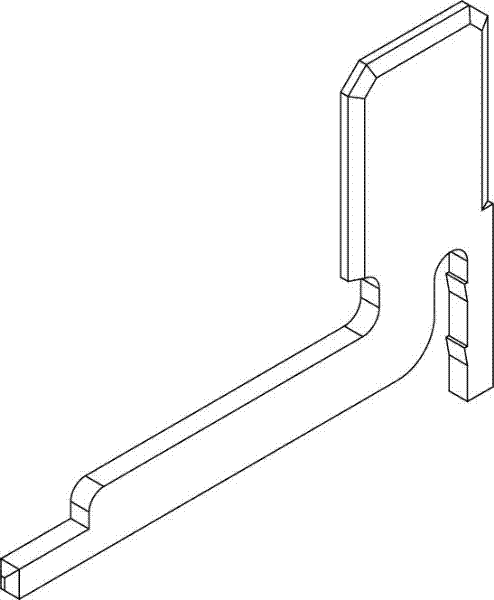

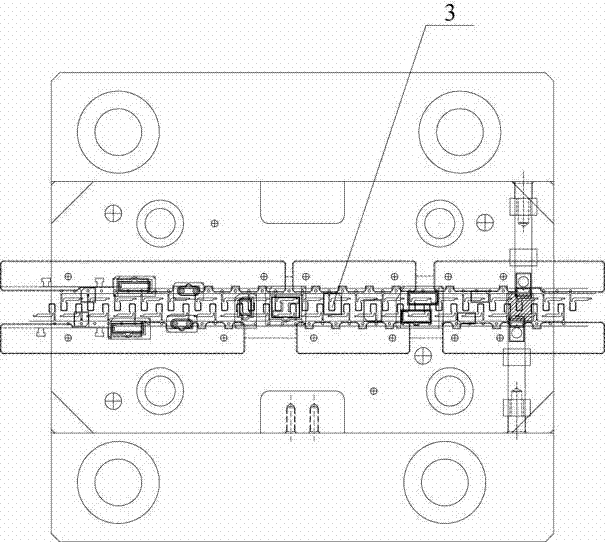

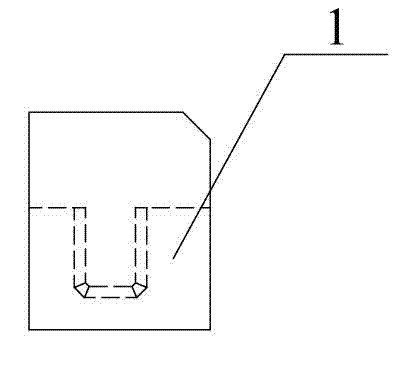

[0019] combine Figure 1 to Figure 6 Describe a kind of chamfering die of the present invention, it comprises the punch and die that match, and punch and die have chamfering upper die 1 and chamfering lower die 2 corresponding to the shape of product chamfering part. The longitudinal sections of the chamfering upper die 1 and the chamfering lower die 2 are straight chamfering or round chamfering. Wherein, the punch is fixedly connected sequentially from top to bottom by the upper die base, the upper backing plate and the chamfering upper die 1 . Die is fixedly connected successively from top to bottom by chamfering lower die 2, lower backing plate, lower die holder and die foot. The chamfering upper die 1 and the chamfering lower die 2 correspond to the shape of the chamfering part of the terminal 3, and both the punch and the die are installed on the punching machine.

[0020] The blank to be processed is located between the punch and the die of the chamfering die, the punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com