Spiral-flow type motor vehicle venting spark quencher

A spark arrester, motor vehicle technology, applied in exhaust devices, machines/engines, mechanical equipment, etc., can solve problems such as poor reliability, low separation and capture efficiency, fire, etc., to achieve stable and reliable performance, flexible configuration, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

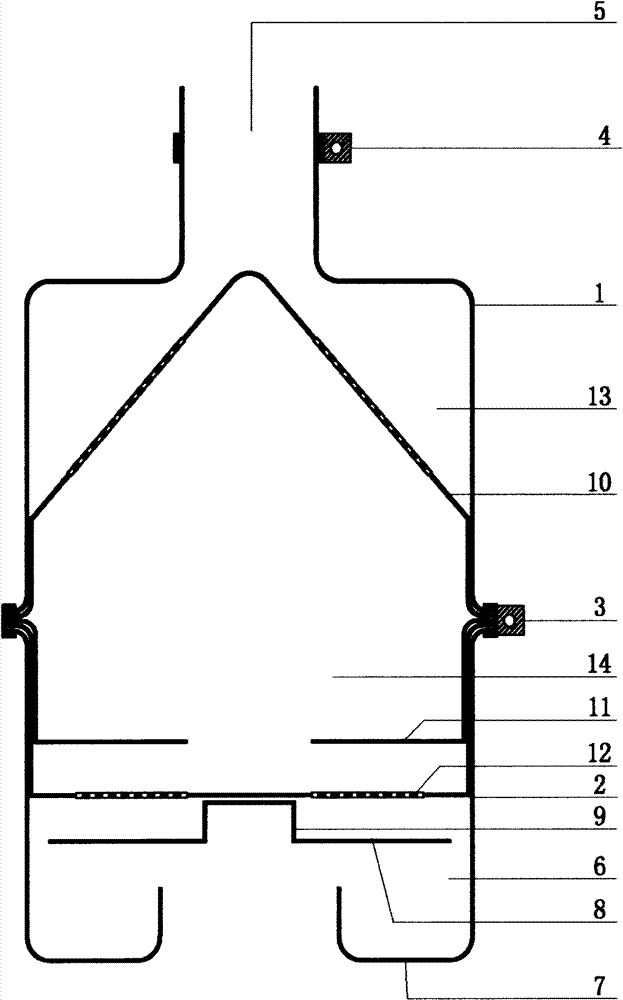

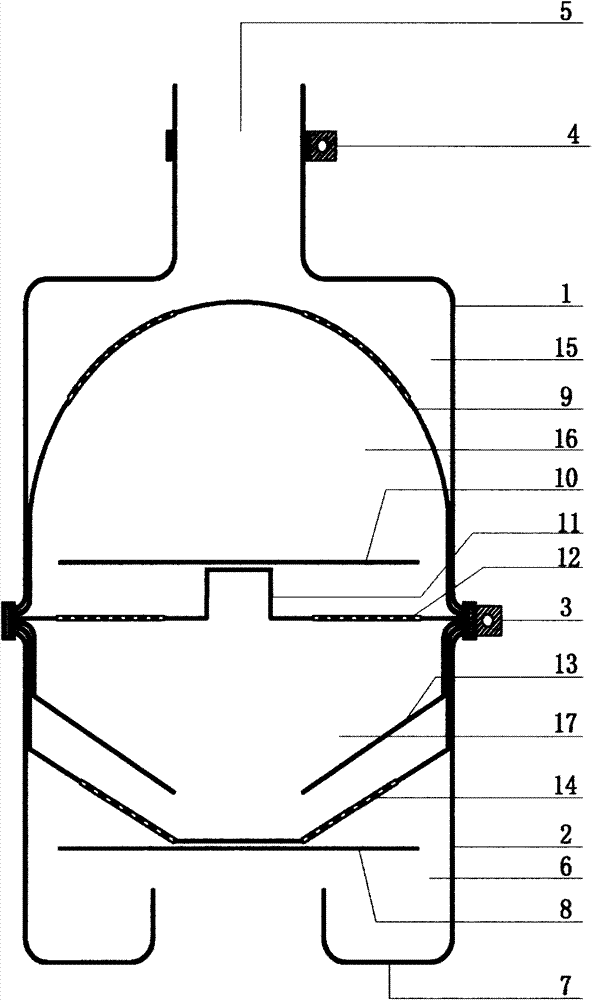

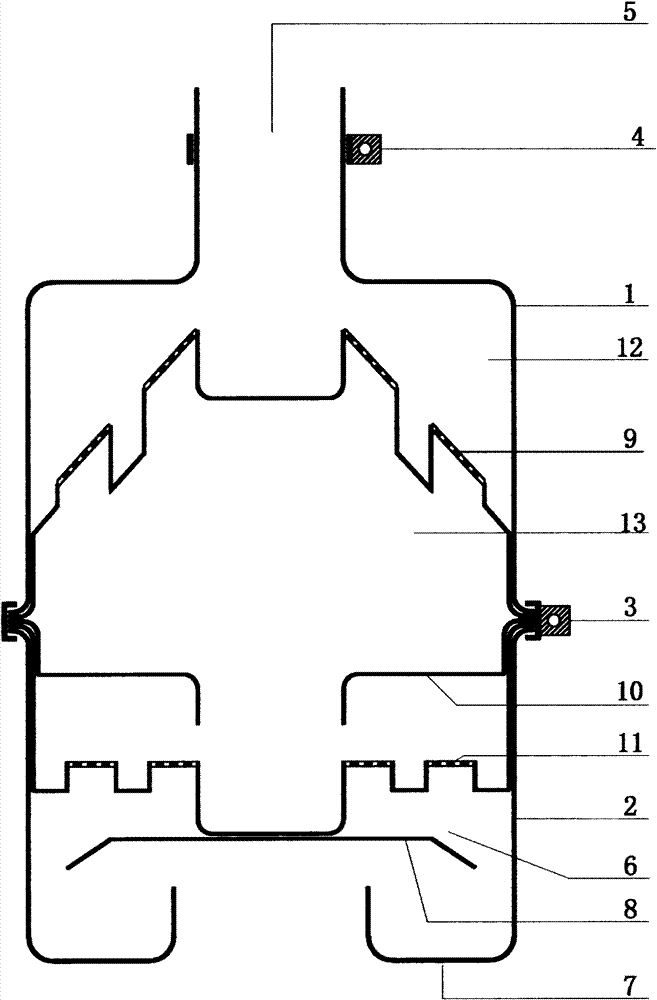

[0024] There are two kinds of substances in the engine exhaust, among which the combustion exhaust gas is gas, and the spark particles are solid, so the engine exhaust is a gas-solid flow. In the gas-solid flow, the density of the spark particles is greater than that of the combustion exhaust gas, so the inertial centrifugal force of the spark particles is greater than that of the combustion exhaust gas.

[0025]In this swirling spark extinguisher, when the gas-solid flow rotates instantaneously around a certain central axis, the inertial centrifugal force causes the spark particles and the combustion exhaust gas to move relative to each other and fly away from the center, so the spark particles and the combustion exhaust gas The flow direction is separated; the separated combustion exhaust gas is discharged through the filter hole and the exhaust hole, while the spark particles flying away from the center are thrown to the filter wall and the turbulent flow chamber; the spark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com