Loss-dilution controlled blasting method in open-pit metal mines

A technology for controlling blasting and open-pit mines, applied in blasting and other directions, can solve the problems of high blasting cost, limited effect, loss and dilution of difficult ore, and achieve the effect of avoiding mutual mixing, avoiding loss or dilution, and avoiding loss of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

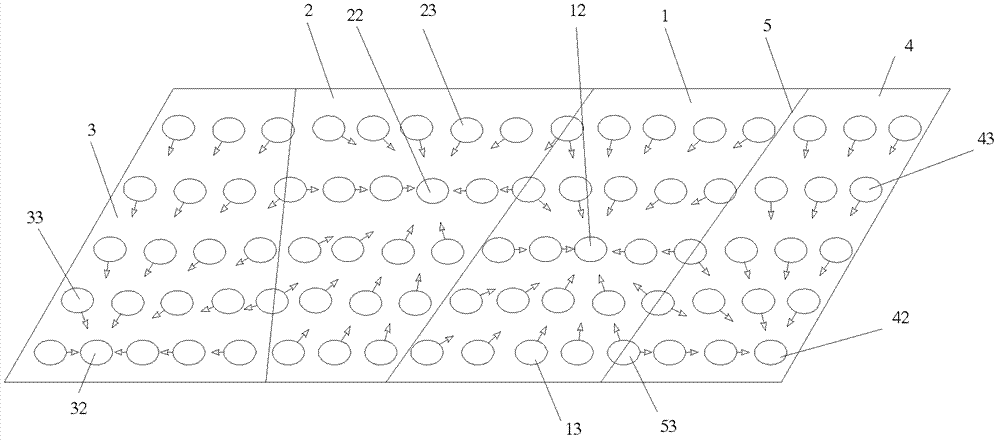

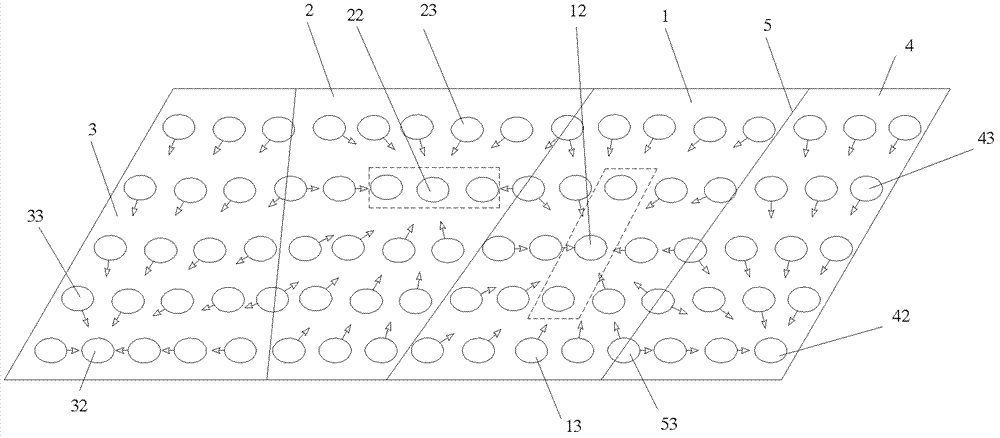

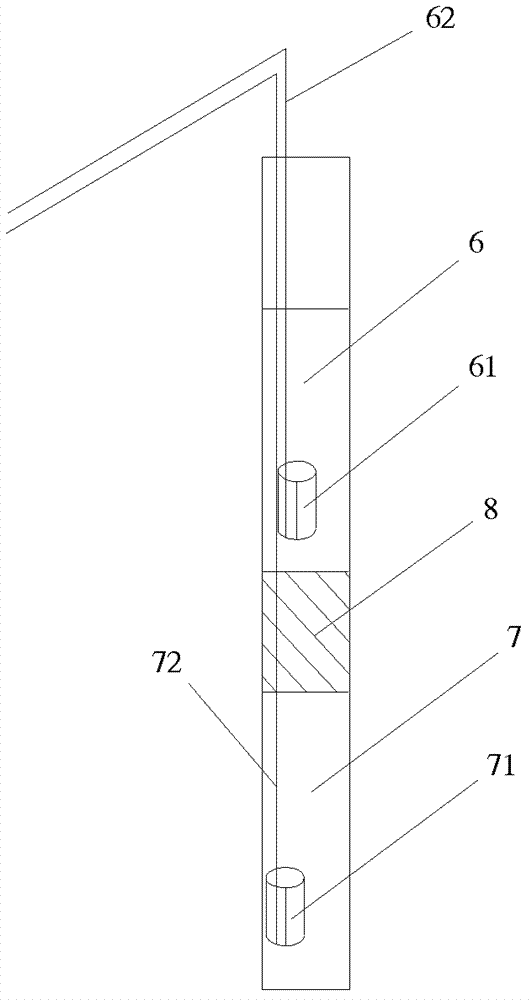

[0038] The invention provides a blasting method for loss and depletion control in an open-pit mine. In the method, blastholes are respectively arranged in the distribution area of ore and rocks, and each blasthole is blasted sequentially according to the moving direction and delay time set by the blasting design. Throw ores and rocks to different areas, and form independent explosive piles.

[0039] Optionally, a digital electronic detonator is used as the detonating device in the blast hole, and the digital electronic detonator itself has no delay time, and the delay time can be set arbitrarily according to the needs of the blasting, including being used for digital electronic detonator identity registration and extension Time-setting IB tables, detonators and digital electronic detonators for detection and detonation of blasting networks, and blasting design software for blasting network design are also included. The delay time is set for each blasthole according to the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com