Pressure testing system and pressure testing method

A pressure test and hydraulic cylinder technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of poor effect and difficult detection of sealing effect, and achieve simple structure, Easy to operate, fast and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention relates to a sealing device, in particular to a nylon end face sealing device for a pressure test system.

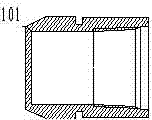

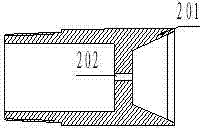

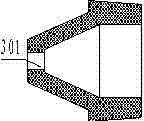

[0032] see Figure 1 to Figure 3 , a kind of pressure test system that the present invention relates to, comprises pressure test tool 4, also comprises solid plug 1, hollow head 2 and nylon packing 3, wherein, one end of solid plug 1 is connected with output end of pressure test tool 4 , the other end is a solid joint 101; one end of the hollow head 2 is connected to the input end of the pressure test tool 4, and the other end is a hollow joint 201, and a liquid hole 202 is provided in the middle of the hollow head 2; one end of the nylon packing 3 can be connected to the hydraulic pressure The cylinder is connected, and the other end is a sealing end surface that can be matched with the hollow joint 201 on the hollow head 2 . The nylon packing 3 is provided with an inner hole 301 that can communicate with the liquid hole 202 .

[0033] The diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com