Method and device for cleaning of engine exhaust gas

An engine, diesel engine technology, applied in mechanical equipment, engine components, combustion engines, etc., can solve problems such as small purification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

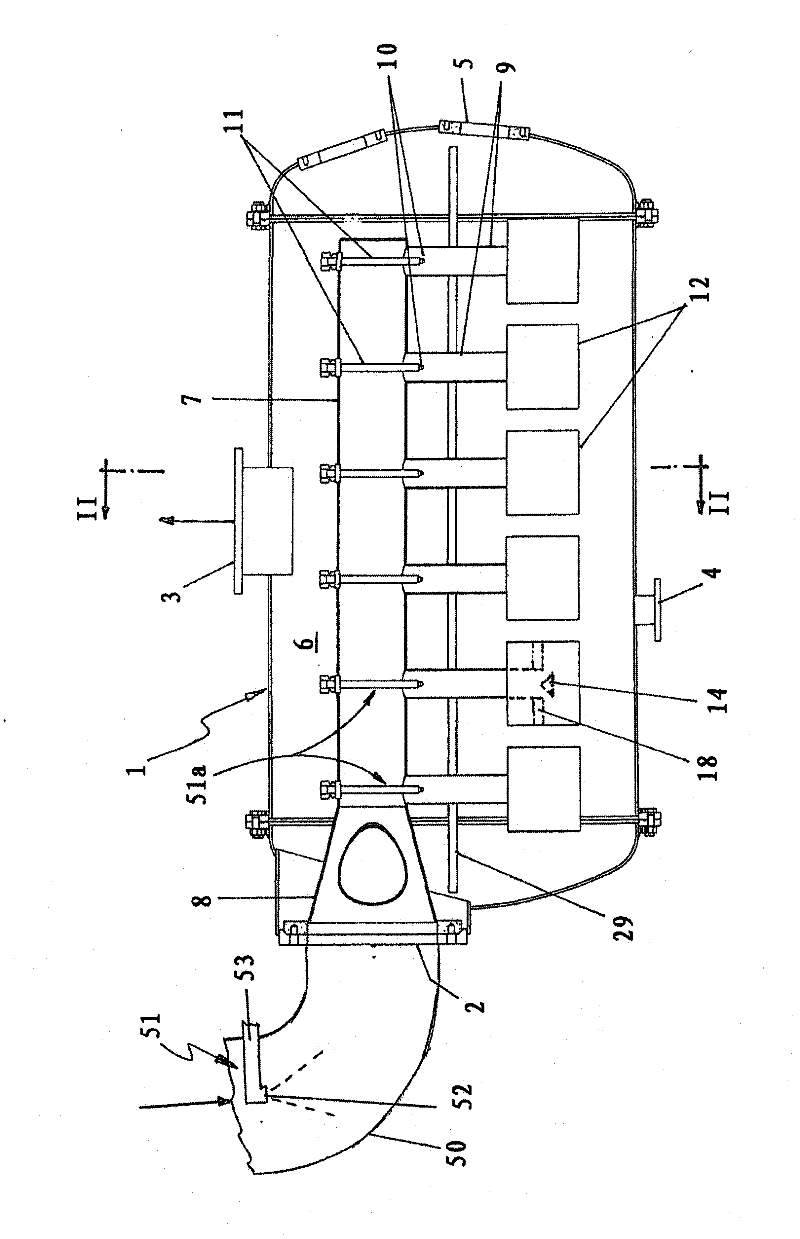

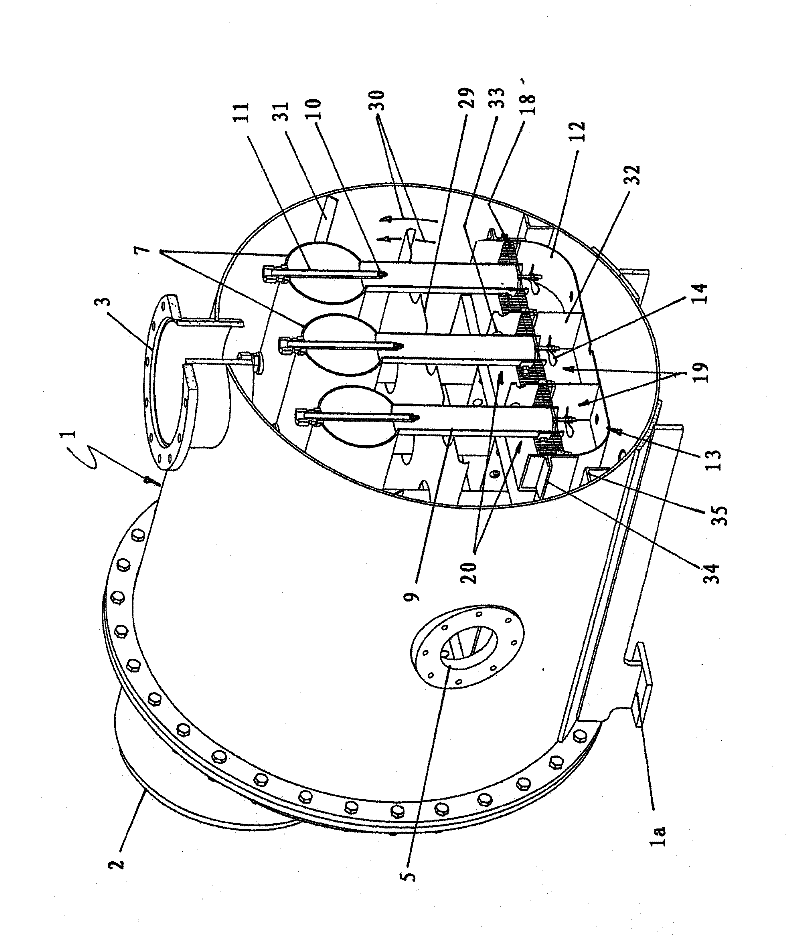

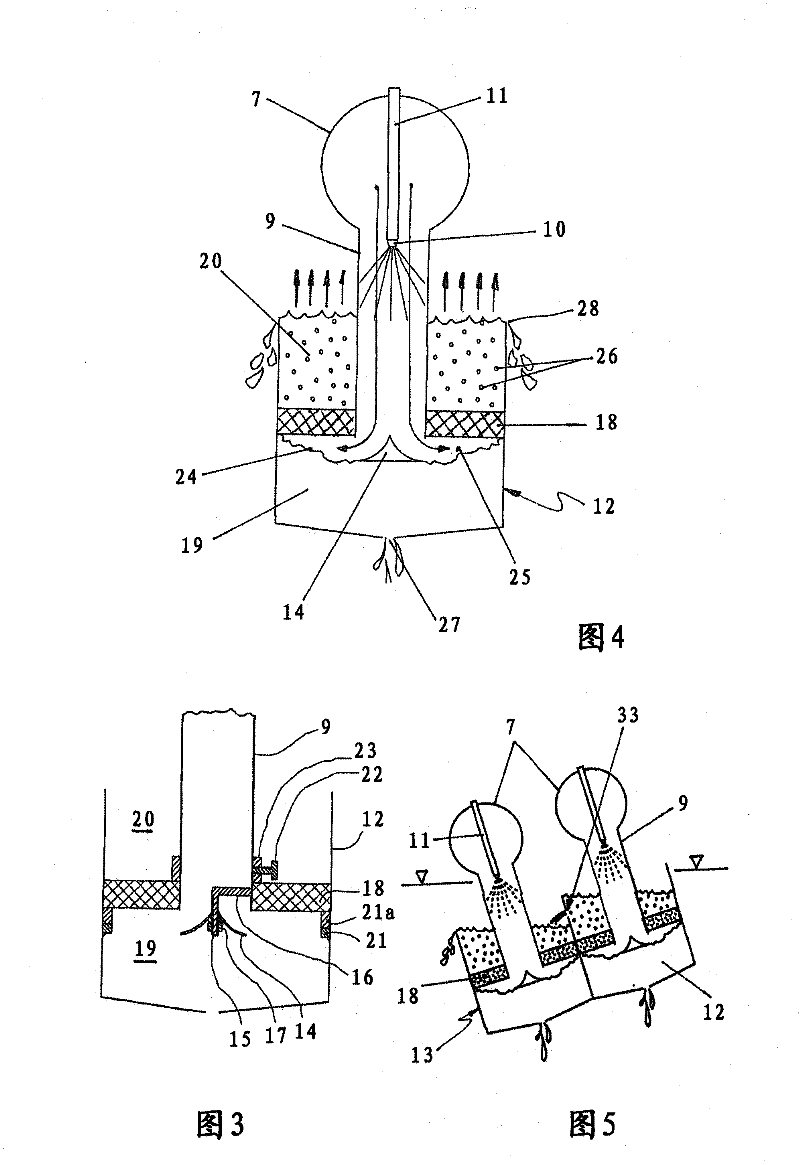

[0021] The main field of application of the invention is large engines, in particular large two-stroke diesel engines, such as can be used, for example, as drives in ships or in stationary power plants or the like.

[0022] based on figure 1 and 2 The exhaust gas purification equipment of the present invention comprises a drum-shaped container 1, which is installed on a support 1a provided with feet. The container 1 has an exhaust gas inlet 2 arranged on the end side and an exhaust gas outlet 3 leading here upwards, and is provided below with a drain opening 4 . The exhaust gas inlet 2 is connected to an inlet line 50 which can be loaded with exhaust gas.

[0023] The drum-shaped container 1 comprises a cylindrical middle part which is closed by two caps which are flanged at the ends. The exhaust gas inlet 2 is arranged here in the upper region of an end-side cover. The exhaust gas outlet 3 is here approximately in the center of the dome region of the cylindrical middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com