Winding machine

A technology of winding machine and yarn guide, which is applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc. It can solve problems such as jamming, easy function failure, skewing, etc., and achieve the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

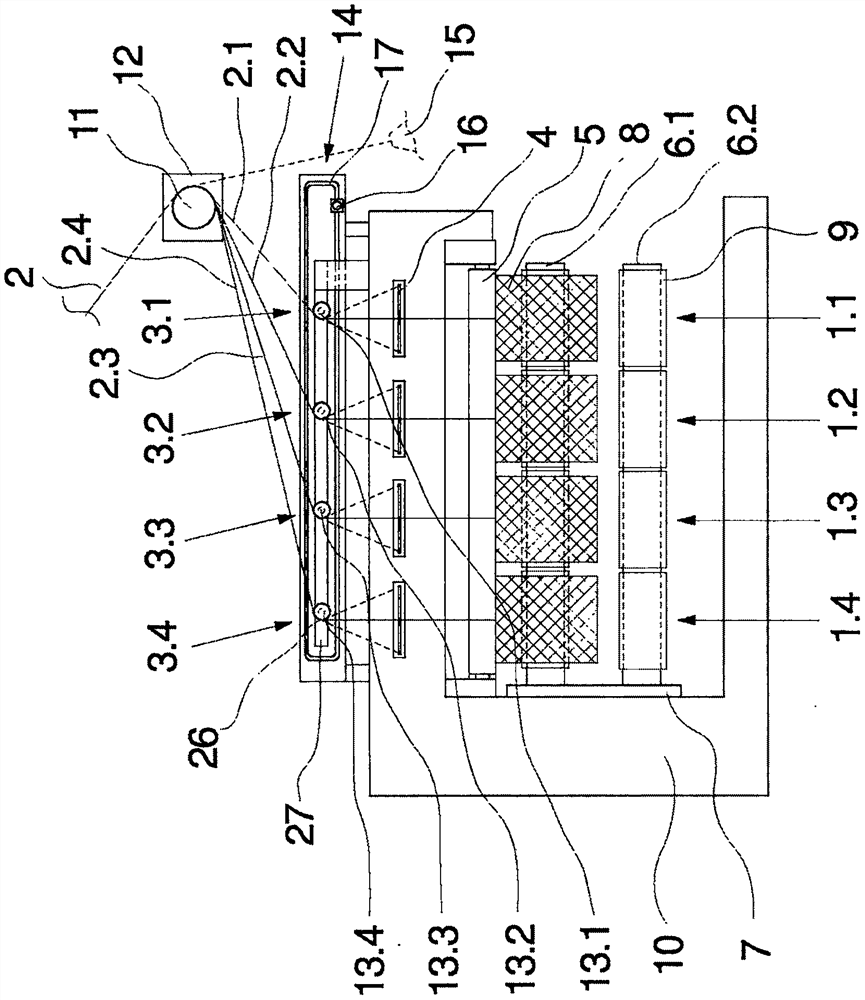

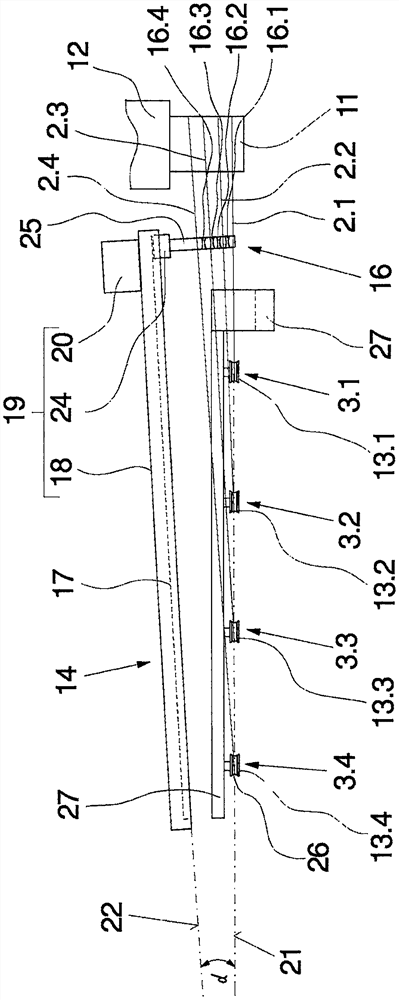

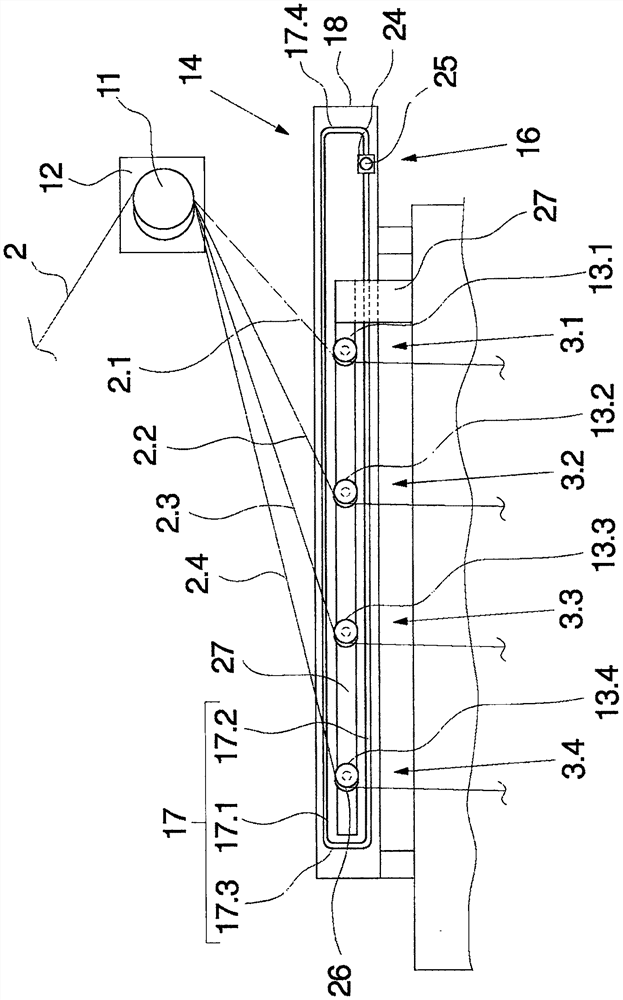

[0024] An embodiment of a winder according to the invention is figure 1 The side view is shown schematically. The winding machine according to the invention in this exemplary embodiment has four winding positions 1.1-1.4 which are arranged side by side in the machine frame. The winding stations 1.1-1.4 are arranged along the winding spindle 6.1 which is held in position in a protruding manner. One yarn of the yarn group 2 is supplied to each winding position 1.1-1.4 and wound into a bobbin 8 . The number of winding positions 1.1-1.4 and the number of threads 2.1-2.4 of the thread group 2 are exemplary here. In principle, such a winder can have up to 16 winding positions side by side.

[0025] The structure of these wrapping bits 1.1-1.4 is designed to be identical, so that the basic structure is described by one of the wrapping bits 1.1.

[0026] The winding station 1.1 has a traversing unit 4, whereby the supply yarn 2.1 is reciprocated in a traversing stroke. The traver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com