Station and yarn guide of rotor spinning machine

An air spinning and yarn guiding technology, which is applied to spinning machines, open-end spinning machines, and continuous winding spinning machines, etc., can solve problems such as unreliable guidance and yarn not allowed to return, and achieve reliable Yarn splicing, preventing interference, and ensuring the safety of splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

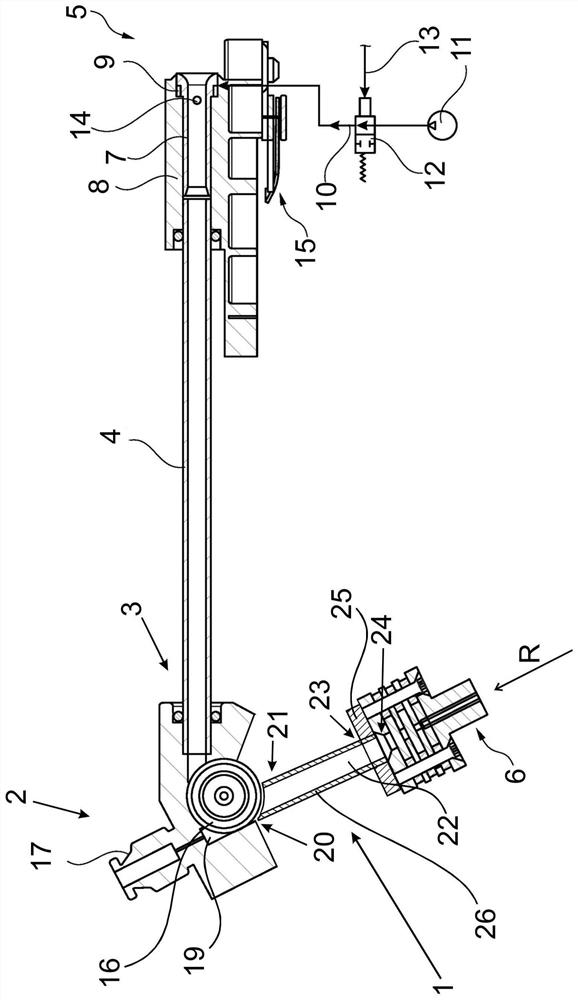

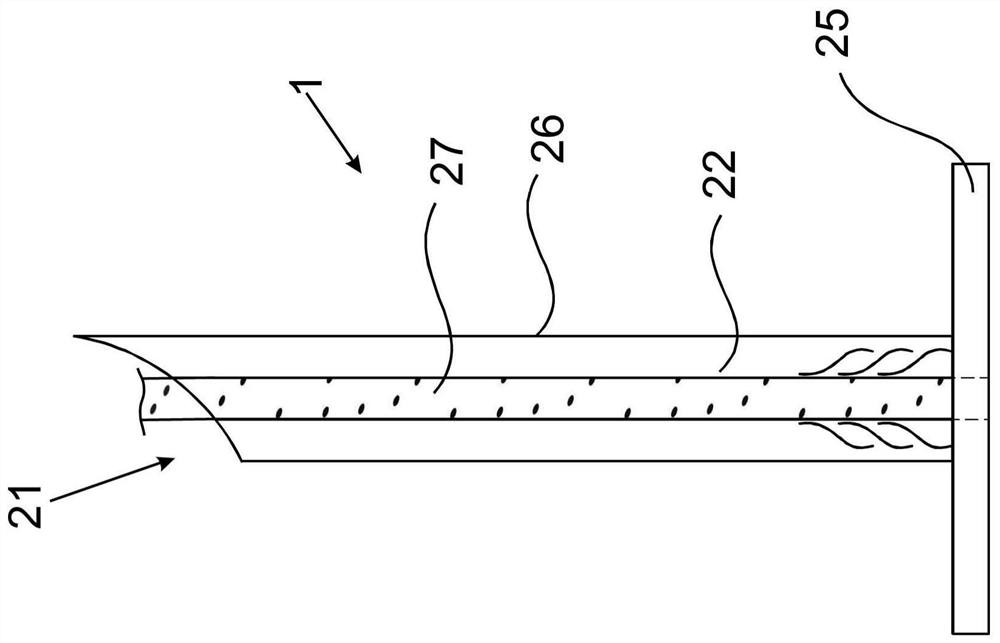

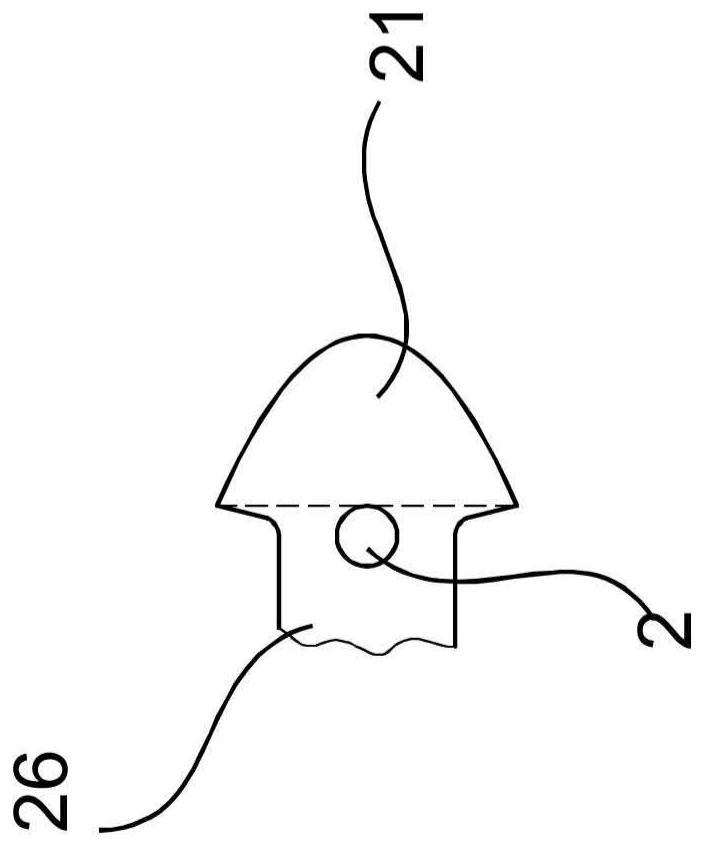

[0056] figure 1 A schematic representation of a yarn guide unit located downstream of the air-jet spinning device 6 along the yarn travel path, the yarn guide unit having a yarn deflection unit 2 connected to the yarn via a yarn guide channel 4 connected to its outlet 3 Prepare device 5 connected. The open-end spinning device 6, the yarn guide unit with the yarn deflection unit 2 and the yarn guide channel 4 and the yarn preparation device 5 are components of the open-end spinning machine station not shown here. During the yarn process, the yarn 27 emerging from the open-end spinning device 6 is wound on a winding bobbin, not shown here.

[0057] During normal open-end spinning, the stored fiber sliver, on its way to the winding bobbin, first passes through a drafting device arranged upstream of the open-end spinning device 6 in the direction of travel R of the fiber sliver, which is here specified be stretched. The drafted fiber sliver is then fed via a pair of delivery ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com