Contact washer system and method for controlling windscreen wiper motor

A technology of contact disc and wiper, applied in excitation or armature current control, circuit, electric switch, etc., can solve the problem of increasing the cost of manufacturing process, and achieve the effect of reliable transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following description of the drawings, the same elements are given the same reference numerals.

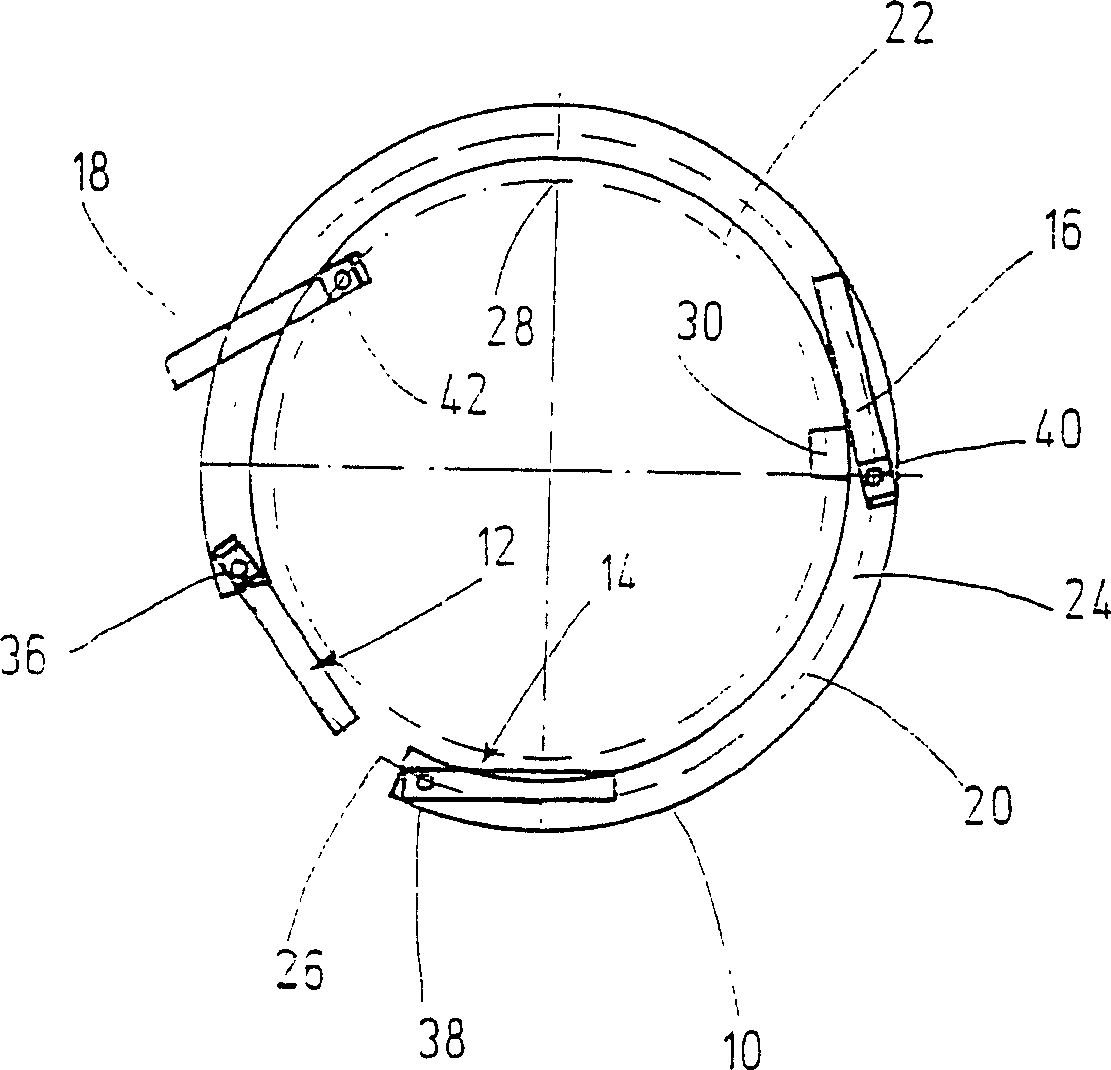

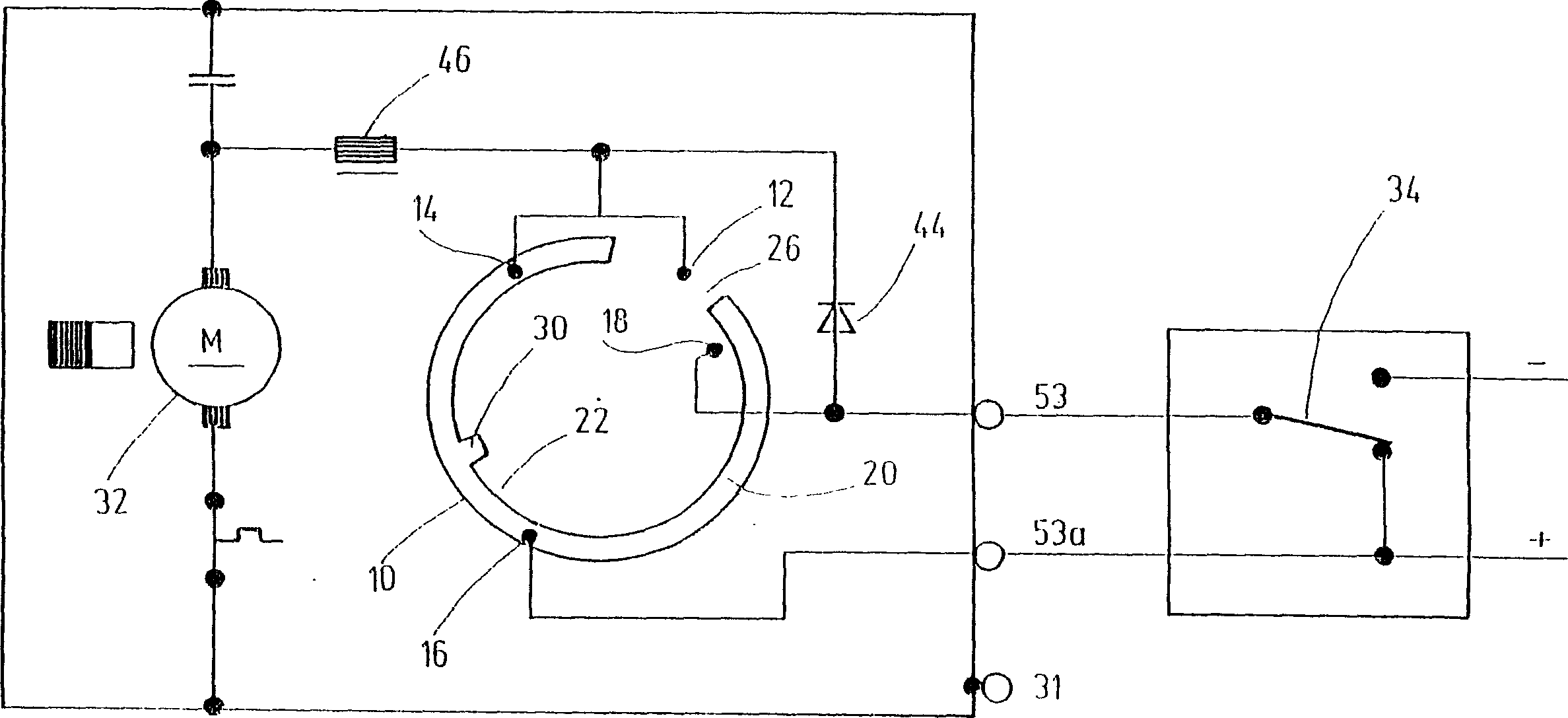

[0033] figure 2A top view showing the contact disk system of the present invention. The contact disk system comprises a contact disk 10 and a plurality of contact pieces 12 , 14 , 16 , 18 . The contact pieces 12, 14, 16, 18 are contact springs. The contact pad 10 has two contact rails 20 , 22 . The first busbar 20 has a relatively long electrically conductive region 24 and a relatively short electrically insulating region 26 , the latter being realized by the break point of the busbar 20 . The first contact rail 20 is located radially outside the second contact rail 22 . The second busbar 22 has a relatively long electrically insulating region 28 and a relatively short electrically conductive region 30 . The conductive area 30 is realized as a short appendage on the conductive area 24 of the first busbar 20 . Two contact elements 12, 14 of the plurality of cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com