Mechanical and electric connection device for a coaxial cable conveying a high frequency signal

A coaxial cable, electrical connection technology, applied in the direction of connecting devices, circuits, electrical components, etc., can solve the problems of high cost, can no longer be easily disassembled, etc., to achieve the effect of low-cost assembly, rapid and efficient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

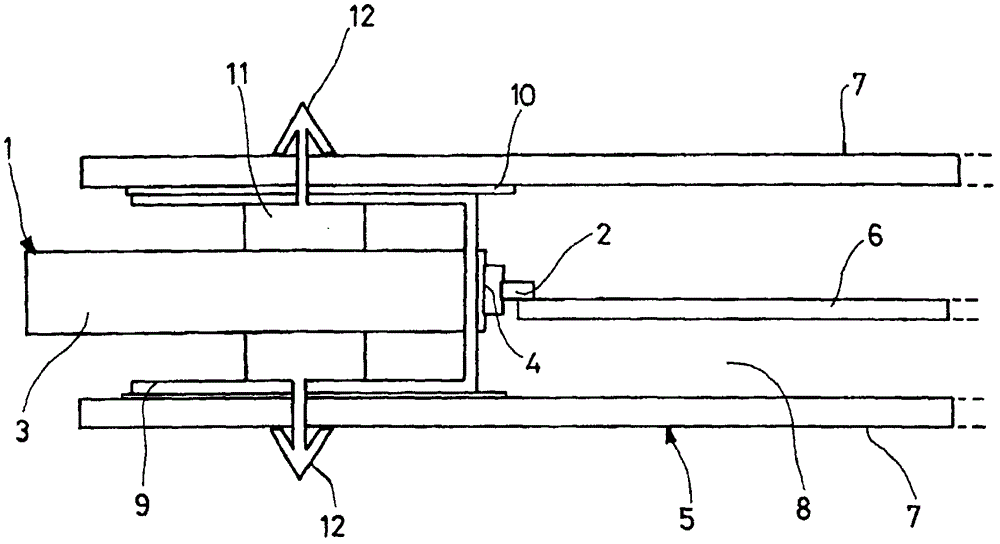

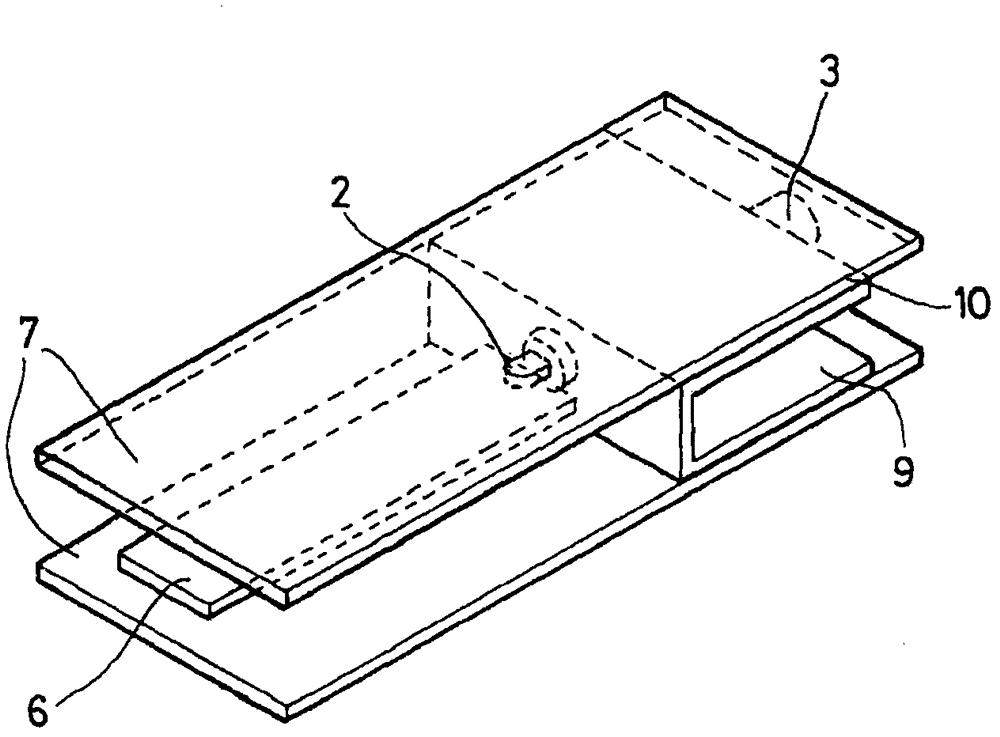

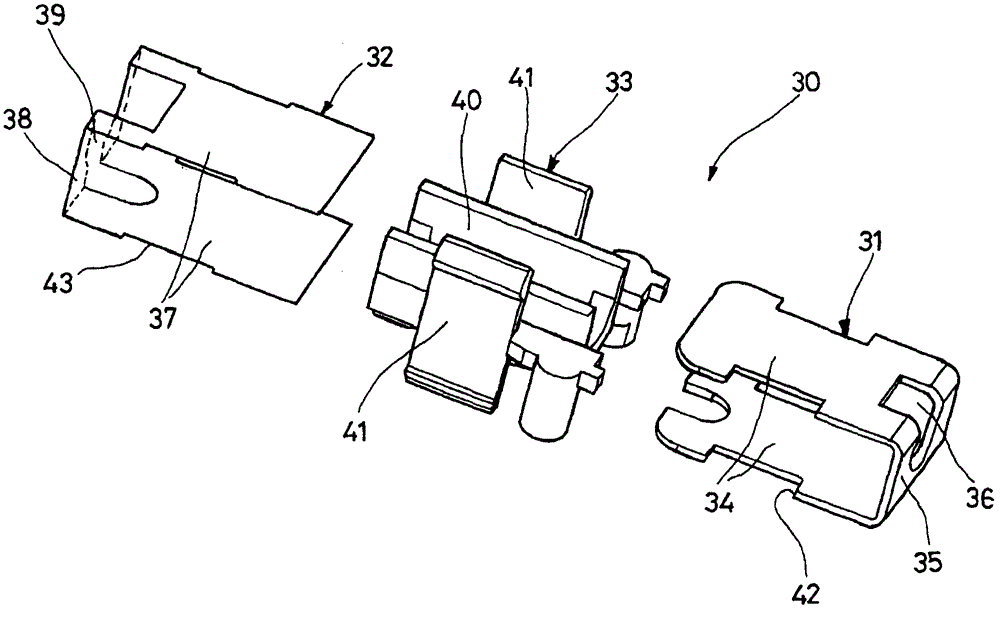

[0052] exist figure 1 and 2 In the embodiment of the mechanical and electrical connection device according to the invention shown schematically above, a coaxial cable 1 comprises a central inner conductor 2 made of metal, an outer conductor 3 receiving an alternating current (often implemented as metal or metal-plated braid) and a layer 4 of dielectric material between the two conductors 2,3. The cable 1 is connected to a multilayer stripline 5 comprising a conductive track 6 sandwiched between two conductive surfaces 7 . The ground metal or metal-plated conductive surface 7 forms the ground plane of the multilayer line 5 . A dielectric layer 8, which in this case consists of air and provides electrical isolation, separates the conductive tracks 6 from the conductor surfaces 7 located on either side. The inner conductor 2 of the coaxial cable 1 is electrically connected to the conductive track 6 of the multilayer line 5, for example by means of welding. The mechanical and el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com