Caprolactam causticization device

A technology of caprolactam and causticization, which is applied in the field of refining and separation of chemical products, can solve the problems of undiscovered mixing and absorption, unsolved ammonia absorption problems, etc., and achieve the effects of reducing investment costs, small pipeline resistance loss, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

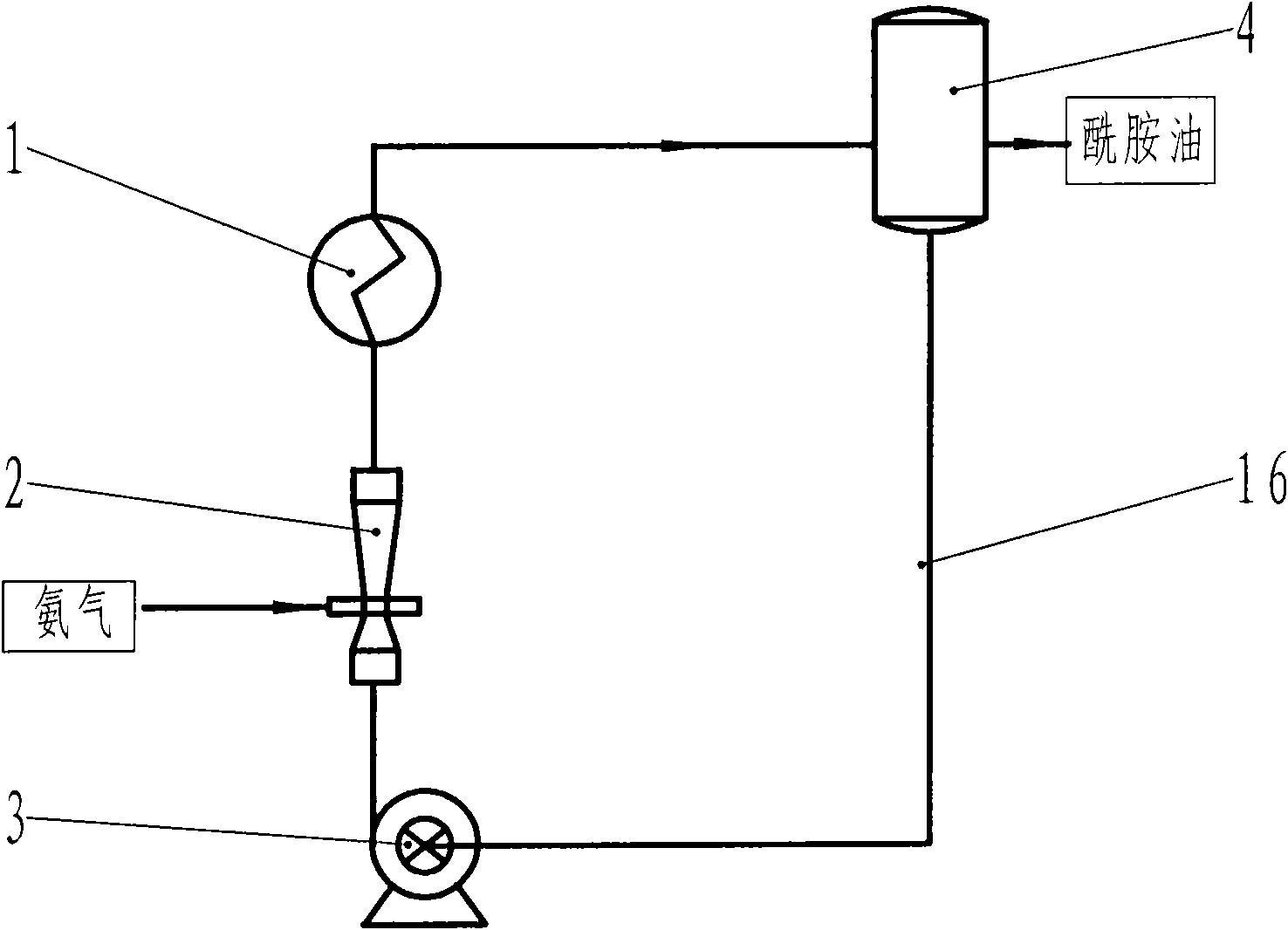

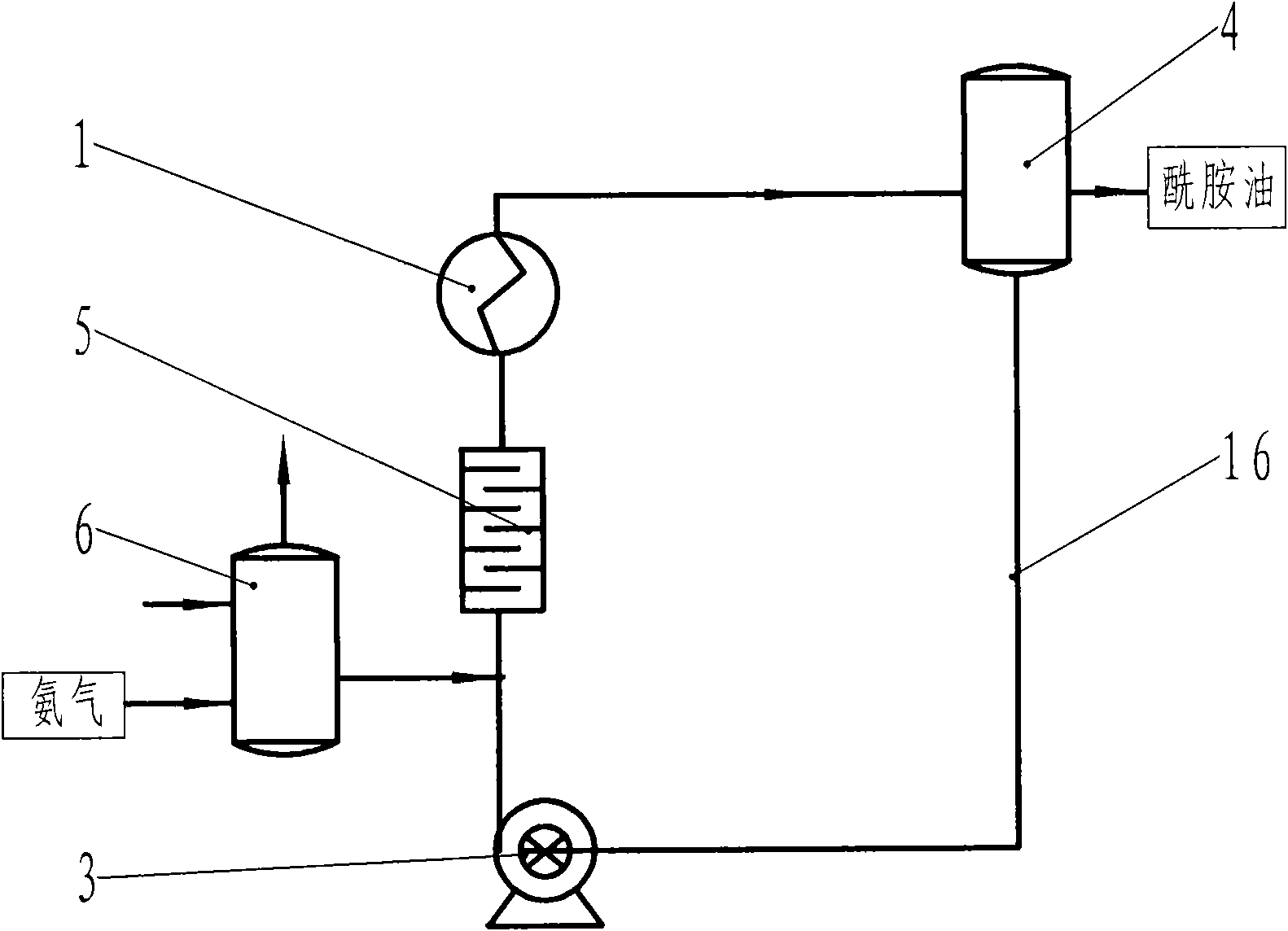

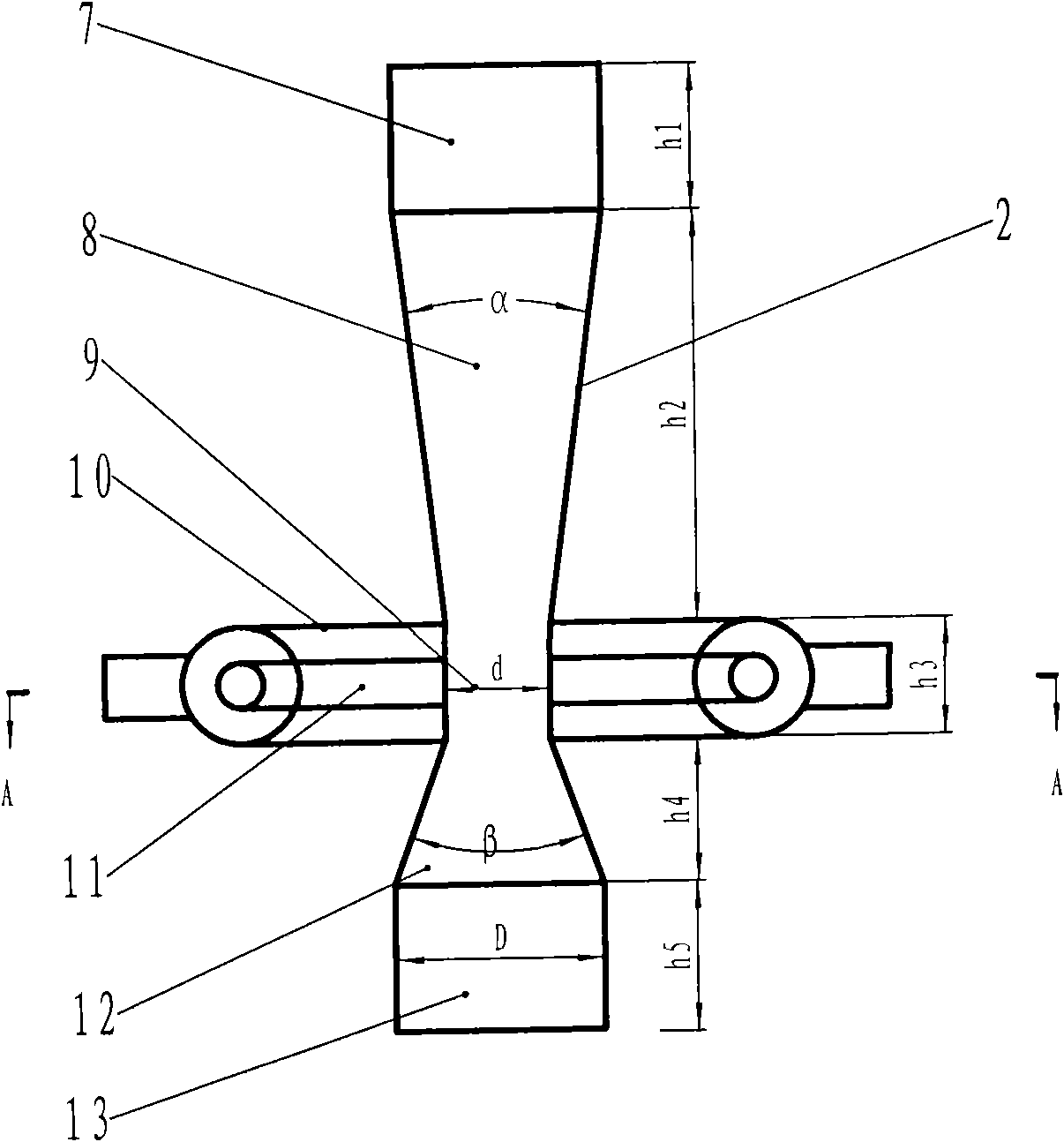

[0016] Caprolactam causticizing device of the present invention such as figure 1 As shown, it is mainly composed of a causticizing reactor 4 , a circulation pump 3 , a Venturi mixer 2 and a mother liquor circulation pipeline 16 . like image 3 , Figure 4 As shown, the Venturi tube mixer includes a Venturi tube, 8 ammonia gas nozzles 11, and an annular ammonia gas distribution pipe 10, and the annular ammonia gas distribution pipe is connected to the throat 9 of the Venturi tube through the ammonia gas nozzles. The diameter D of the mother liquid circulation pipeline is 20cm, the diameter of the inlet section of the Venturi tube is 20cm, and the length of the inlet section is 30cm (1.5D). The diameter of the throat of the Venturi tube is 10cm (d=0.5D), the length of the throat is 10cm; the length of the constricted section is 27cm, and the included angle of the constricted section is 21°. The included angle of the expansion section of the Venturi tube is 8°, and the length...

Embodiment 2

[0019] In another mode of the present invention, the diameter of the annular ammonia gas distribution pipe is 1 cm; the diameter of the ammonia gas inlet pipe is 0.25 cm, and the speed at which the ammonia gas enters the mixing device is adjusted in the range of 1 to 5 m / s; 4 nozzles with a diameter of 1 cm are evenly distributed in the Circumference, connecting the throat of the Venturi tube and the annular ammonia gas distributor, the resistance of the nozzle tube is 10 times the distribution resistance of the circulation tube, which can evenly distribute the ammonia gas to the 4 nozzles. Amide oil was obtained from the caprolactam unit of the Chemical Division of Sinopec Shijiazhuang Refining and Chemical Company. The flow rate of ammonia gas is 0.5~1kg / h.

[0020] In order to test the mixing effect of the Venturi mixer, the free ammonia concentration at the top of causticizing reactor 4 was measured. determined. When the flow rate of ammonia gas is 1.0kg / h, the absorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap