Bending molding structure for stamping mould

A technology of bending forming and stamping dies, which is applied in the field of stamping dies, can solve the problems of low processing efficiency, low processing precision, and high production cost, and achieve the effects of improving processing efficiency, improving processing accuracy, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

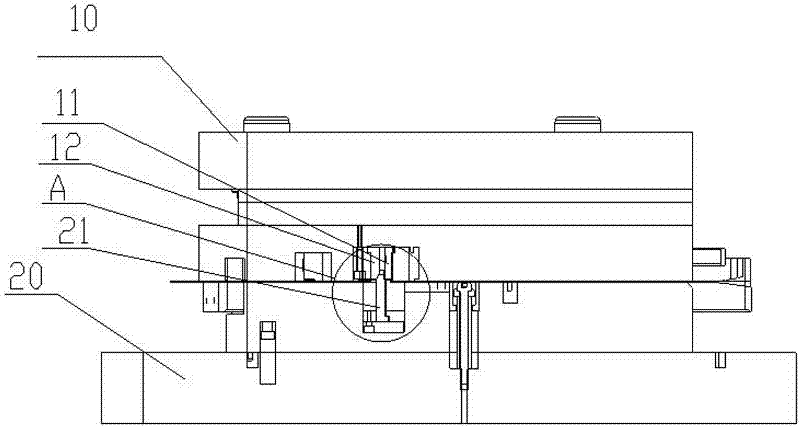

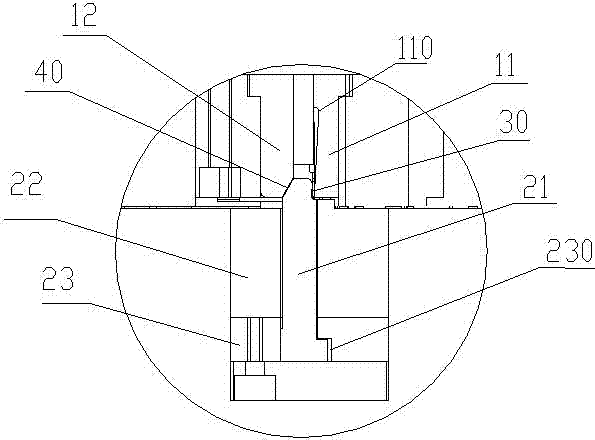

[0023] see figure 1 with figure 2 , the bending forming structure for the stamping die of the present embodiment, which includes an upper mold 10 and a lower mold 20 adapted to the upper mold 10, the lower mold 20 is provided with a mold core 22 that can float up and down and is installed under the mold core 22 The mold core fixing plate 23, the lower end surface of the mold core fixing plate 23 is processed with an installation groove 230, a swingable movable insert 21 is installed on the lower mold 20 through the installation groove 230, and the upper mold 10 is fixed with a movable insert 21 The matching bending punch 11 and the angle punch 12 that controls the swing angle of the movable insert 21.

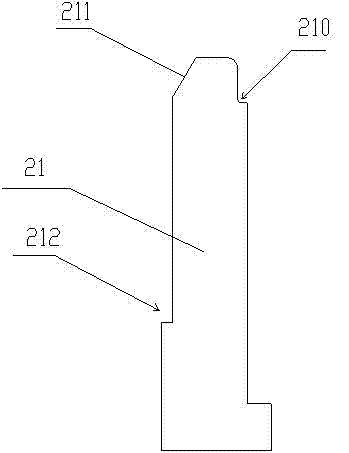

[0024] In this example, see image 3 , the lower end of the movable inlet 21 is "L"-shaped, and is movably installed in the installation groove 230; the upper end of the movable inlet 21 passes through the mold core 22 and is inserted into the mold cavity on the mold core 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com