Trash can cover with sensing device

A technology of sensing device and trash can, applied in the field of automatic flip-top trash can, can solve the problems of increased cost, unstable center of gravity, scratches or damage to the cover 27, and achieves the requirements of design, cost control, and concise design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

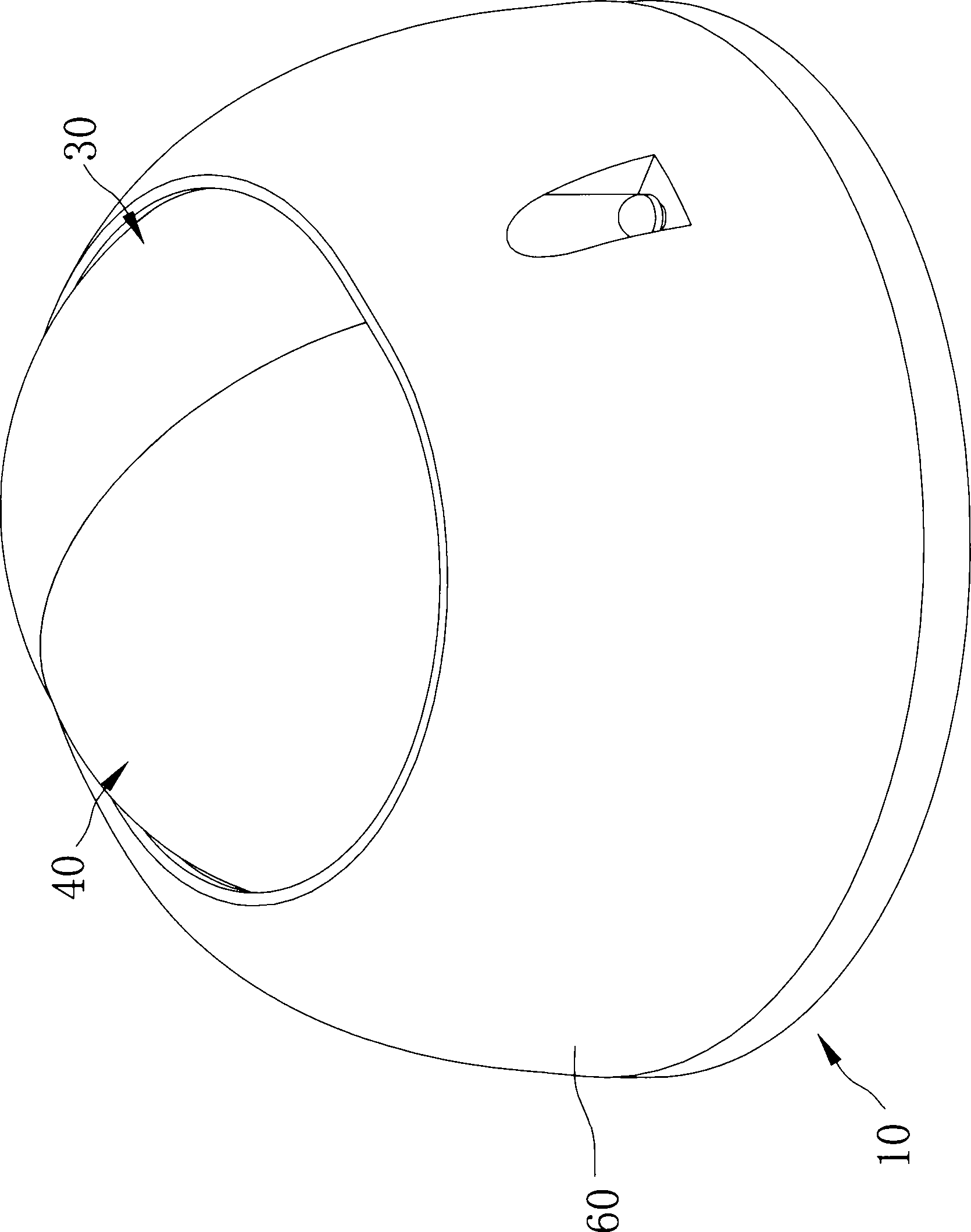

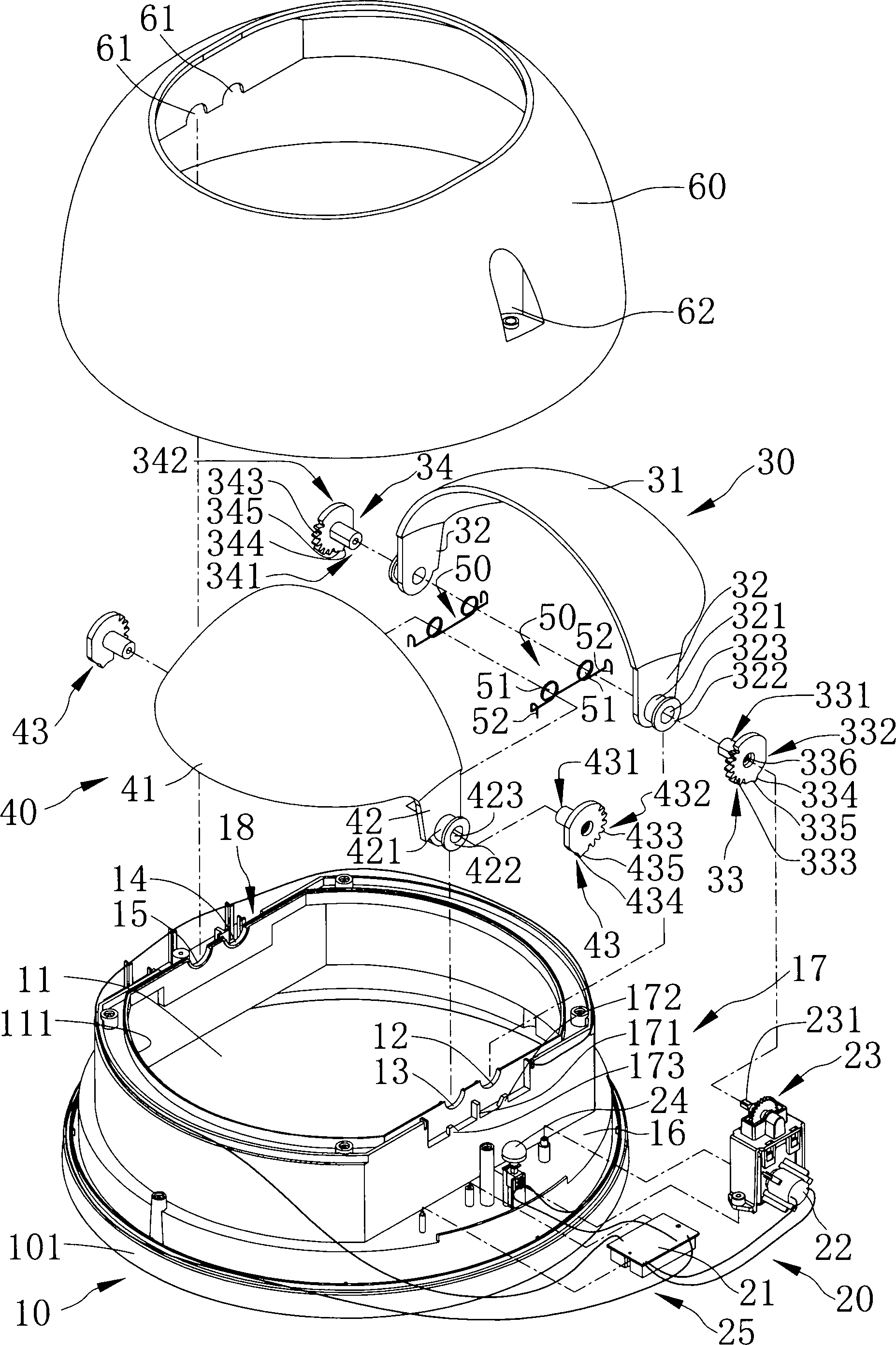

[0041] refer to figure 1 and figure 2 , is a three-dimensional appearance view and a three-dimensional exploded view of the trash can lid with the sensing device of the present invention. The trash can lid with sensing device of the present invention includes a main body 10 , a driving mechanism 20 , two split first lids 30 and second lids 40 , at least one elastic member 50 and a cover 60 .

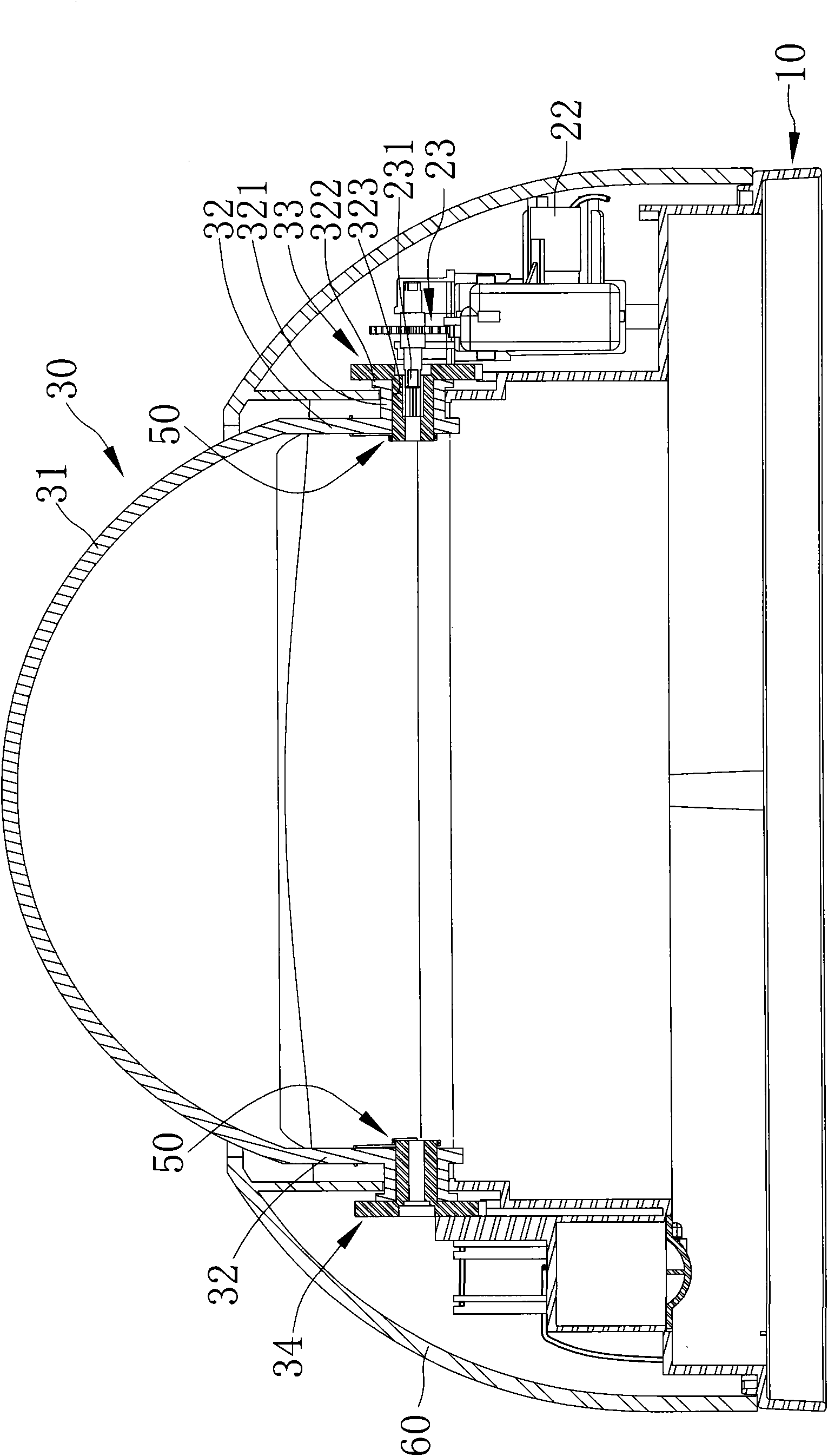

[0042] Also refer to image 3 , Figure 4 and Figure 5 , is a cross-sectional view of the trash can lid with the sensing device of the present invention. The main body 10 is capable of receiving the trash can body, the main body 10 includes an outer peripheral edge 101, and the main body 10 is provided with an opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com