Rapid anchoring method for coal mine roadway anchor rod

A technology of coal mine roadway and anchoring method, which is applied to the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems that the installation process cannot be solved, and is not prominent, so as to reduce the self-stabilization time, reduce the degree of damage, and slow down the weakening process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

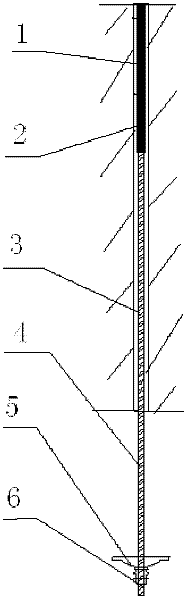

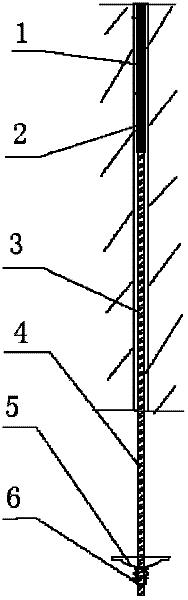

[0016] The technical solution is further described with reference to the accompanying drawings.

[0017] 1. Drill bolt holes 3 according to the design on the surrounding rock of the roadway, and use MQT-120 pneumatic bolt drilling rig or 7665 pneumatic drill to drill holes.

[0018] 2. Fill the bolt eye 3 with two kinds of resin medicine rolls with different coagulation times in turn. The first kind of resin medicine medicine is quick-setting resin medicine medicine volume 1 with a setting time not greater than 10 seconds, and the second kind of resin medicine medicine medicine volume is ordinary Resin drug roll 2; push into the fundus with anchor rod 4;

[0019] 3. After clamping the bolt nut 6 with a drilling rig with a special sleeve, continuously push and rotate it with a torque of 150N.m, and stir the ordinary resin drug roll 1 and the quick-setting resin drug roll 2 once to the bottom. Still keep rotating after the end, until the quick-setting resin drug roll 1 solidifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com