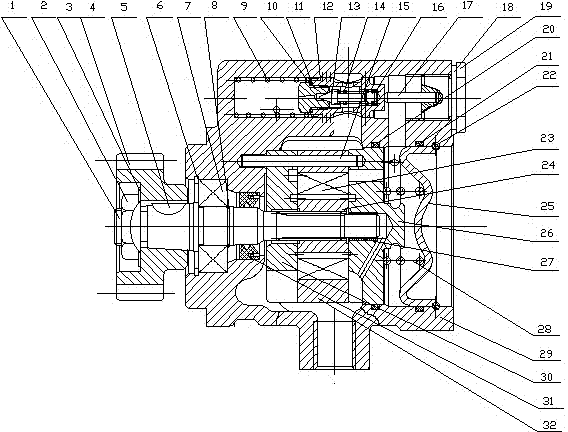

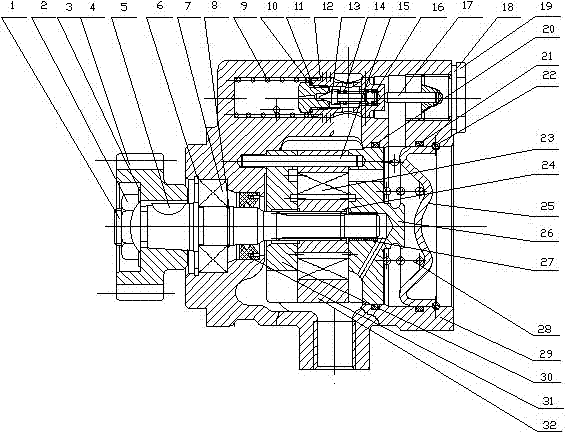

Integral internal-discharge-type power steering pump

A power steering pump, the overall technology, applied in the direction of fluid steering mechanism, rotary piston pump, pump, etc., can solve the problems of driver fatigue, poor operation flexibility, large steering torque, etc., and achieve low noise and safety The effect of high, high work pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The integrated internal leakage power steering pump of the present invention realizes flow control and pressure control on the basis of the working principle of the quantitative pump. The working principle of the quantitative pump is to provide pressure and flow for the steering system. In direct proportion, the higher the speed, the greater the flow. The principle of flow control is to ensure that the flow of the steering pump input into the steering system tends to be constant. Flow control principle: When the oil pumped out of the oil chamber passes through the flow control damping hole, a pressure drop is generated to form a pressure difference. The greater the flow rate through the damping hole, the greater the pressure difference, and the oil at both ends of the damping hole directly acts on the flow control valve. At both ends, when the pressure difference breaks the equilibrium state of the flow control valve, the valve overcomes the spring force and begins to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com