Fan structure

A fan and fan blade technology, applied in the field of fan structure, can solve the problems of low structural rigidity, increased cost, and easy to arouse structural resonance, etc., to achieve the effect of maintaining aesthetics and design, increasing air volume, and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

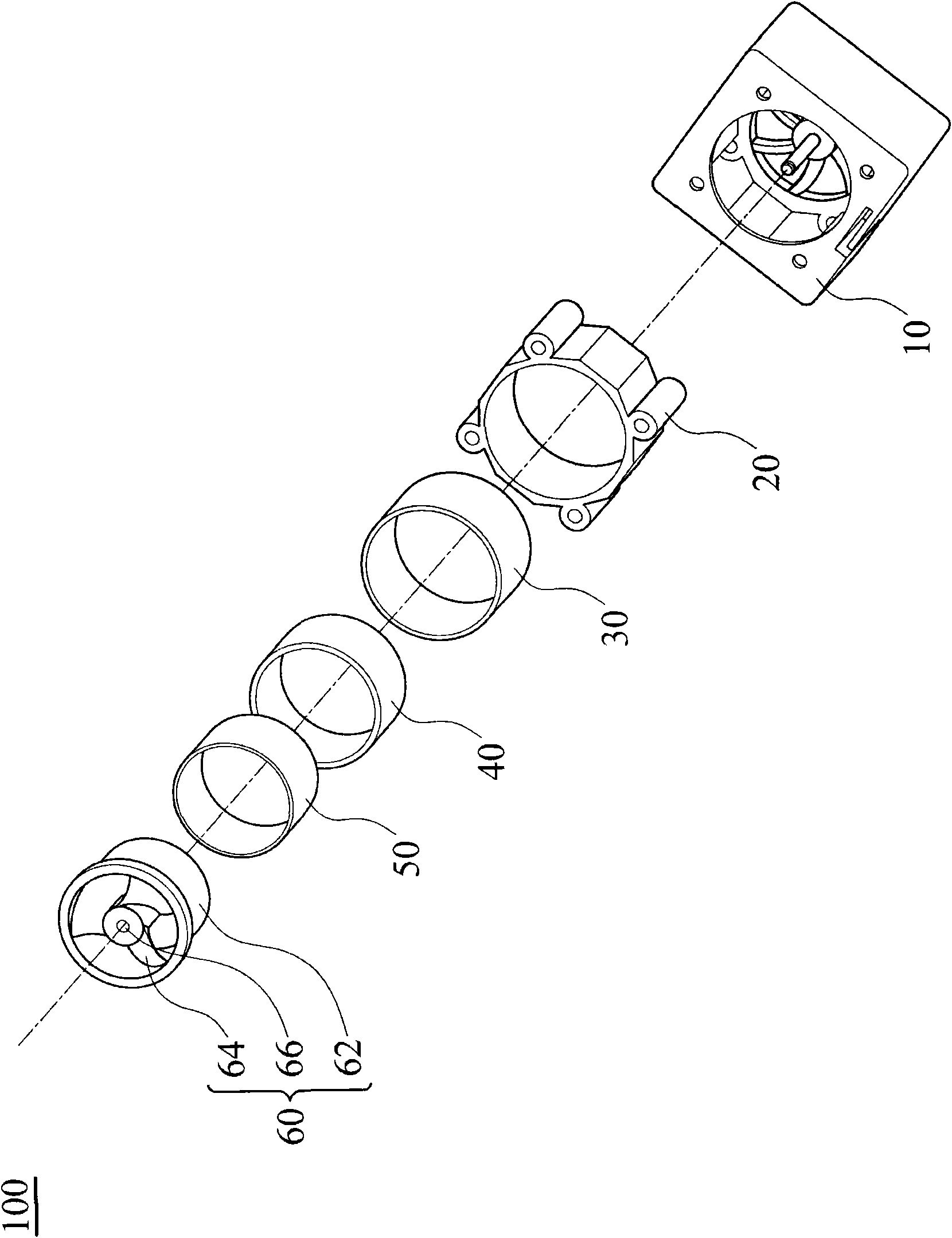

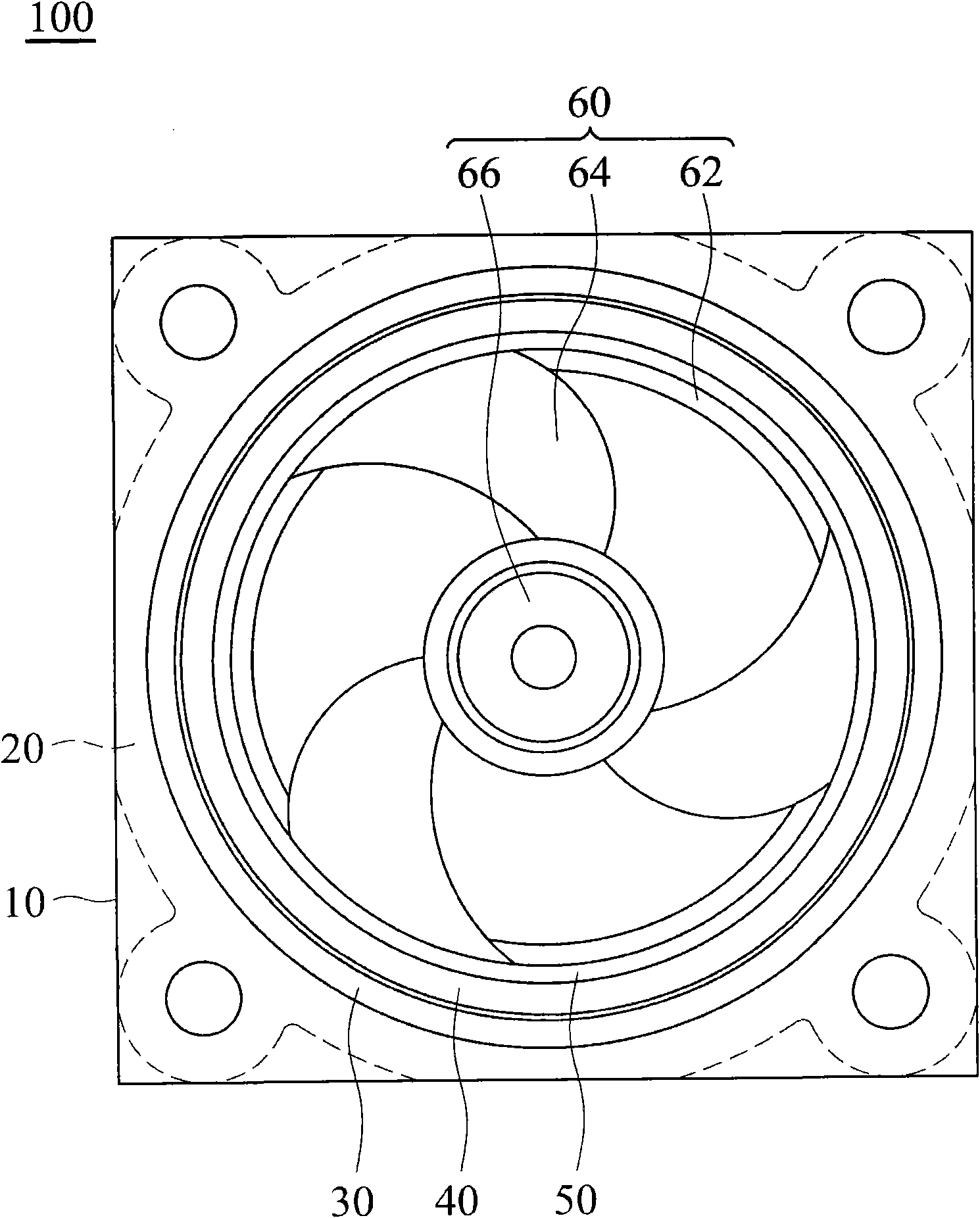

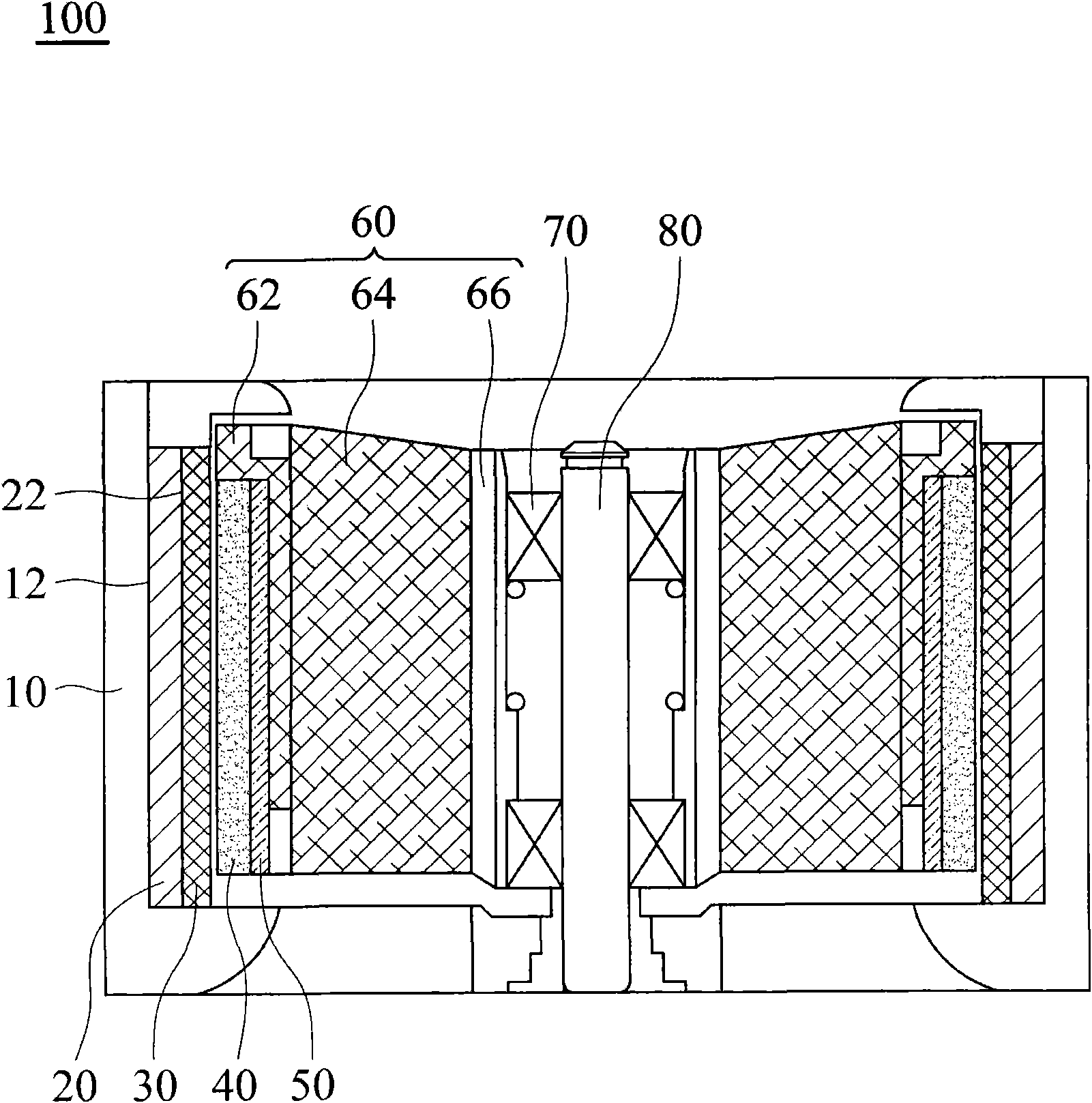

[0063] figure 1 An exploded perspective view showing an embodiment of the fan structure of the present invention. figure 2 for figure 1 The plan view of the assembled fan structure. image 3 for figure 2 cutaway view. As shown in Figures 1, 2 and 3, the fan structure 100 of the present invention includes a frame body 10, a silicon steel sheet group (magnetic conductive element) 20, a winding group 30, a permanent magnet 40, an iron ring 50 and 60 for a fan. The frame body 10, the silicon steel sheet group 20 and the winding group 30 constitute the stator of the fan structure, while the permanent magnet 40, the iron ring 50 and the fan 60 constitute the rotor assembly. The structure of the stator will be described first below.

[0064] The silicon steel sheet group 20 is stamped and formed by arranging a plurality of silicon steel sheets, and then placed in a mold of an injection molding machine, and then the injection molding material is formed to form the frame body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com