Gas valve device and gas stove with same

A gas valve, gas technology, applied in valve device, valve operation/release device, valve details, etc., can solve the problems of increasing manufacturing cost, reducing service life, hidden safety hazards, etc., to improve the degree of intelligent control and reduce safety hidden dangers and the effect of reducing mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, scheme and beneficial effect of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

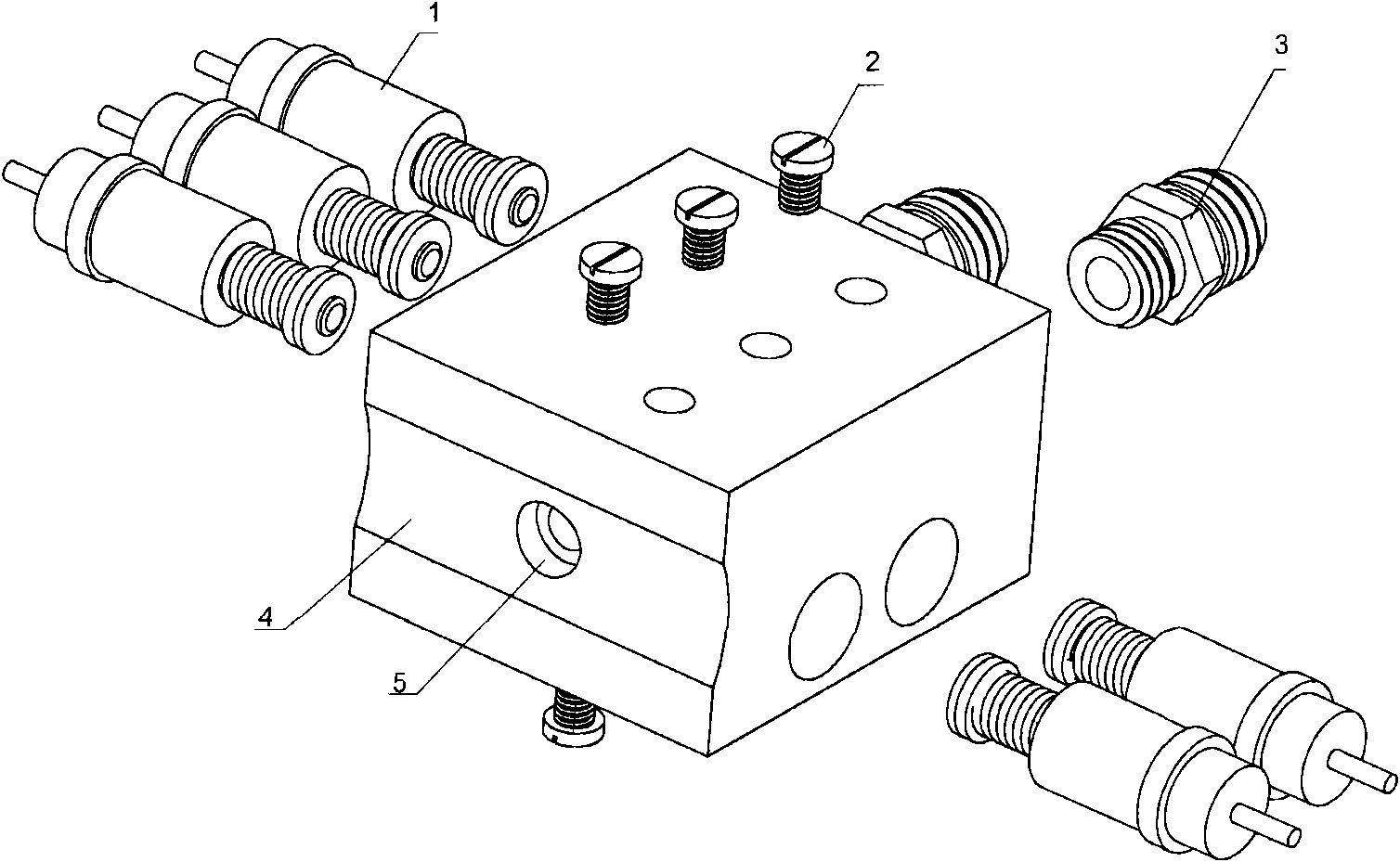

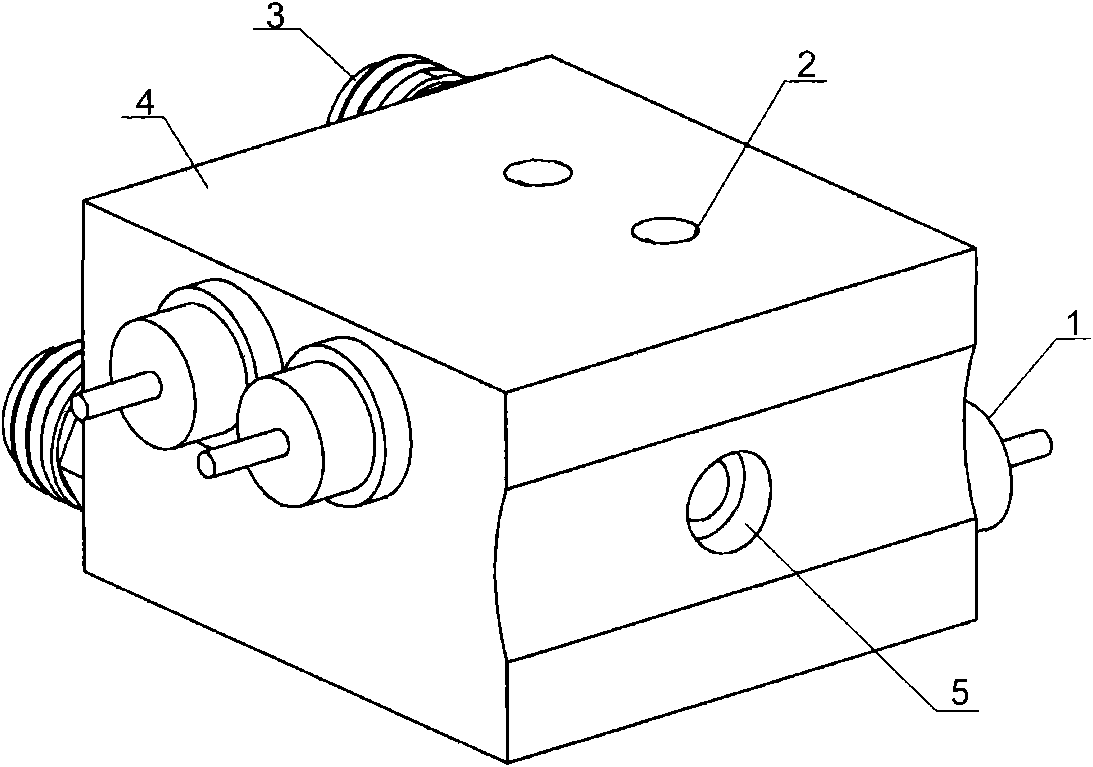

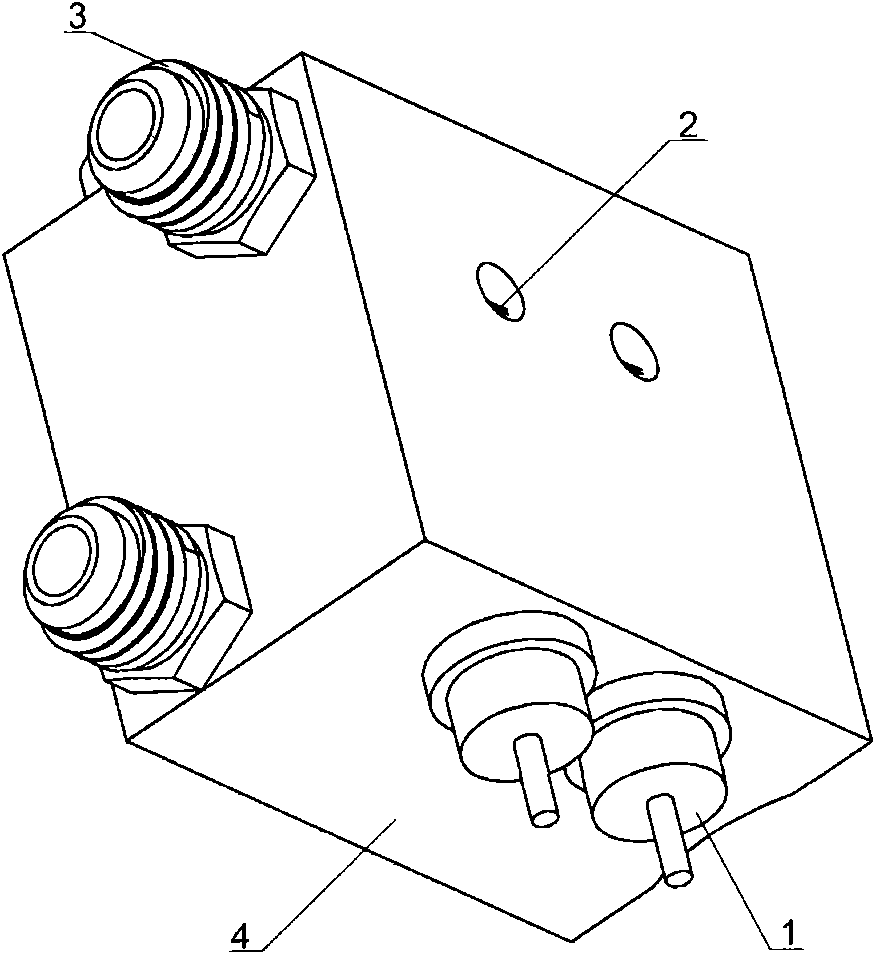

[0045] An example of a gas valve device proposed by the present invention Figures 1 to 6 As shown, it includes a gas inlet 5, a gas flow channel and a nozzle 3, the gas inlet 5 communicates with the main gas pipe, and the main gas pipe transports the gas to the gas inlet 5, and one end of the gas flow channel communicates with the gas inlet 5, and the gas flow The other end of the channel is connected with the nozzle 3, and the gas flowing in from the gas inlet 5 is delivered to the nozzle 3 after passing through the gas flow channel, and the nozzle 3 is used for supplying gas to the burner. The nozzle 3 includes a first nozzle and a second nozzle, the first nozzle is used to supply air to the small central flame cap of the burner, and the second no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com