Environment-friendly safe multi-roller common-driving RGV tracked intelligent conveying device

An intelligent conveying and safe technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of heavy maintenance workload, inability to operate synchronously, breakage of electrical appliances, etc., to achieve small maintenance workload and easy installation And maintenance, the effect of running fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

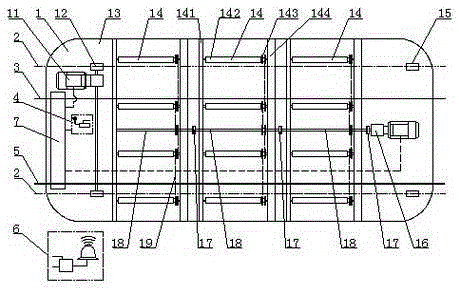

[0007] see figure 1 , the present invention comprises dolly 1, and described dolly 1 comprises driving motor speed reducer 11, driving wheel 12, driven wheel 15 and car body 13, and described driving motor speed reducing machine 11 is contained in the left side of car body 13, and described driving wheel 12 Be contained on the output shaft of drive motor reducer 11, described driven wheel 15 is contained in the right side of car body 13, also comprises roller bed drive motor reducer 16, power supply cable 3, on-board wireless receiving device 4, bar code belt 5, Wireless transmitting device 6, electric control box 7, two ground rails 2, several on-board roller beds 14, several shaft couplings 17, several transmission shafts 18 and several chains 19, the electric control box 7 is equipped with There is a power-taking board and a code reader, and each of the on-board roller beds 14 includes a left support plate 141 of the roller bed, a right support plate 144 of the roller bed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com