Water tank with jacketed heat exchanger

A heat exchanger and water tank technology, applied in the field of water tanks with jacketed heat exchangers, can solve the problems of low water temperature, affecting the heat production rate and thermal performance, etc., achieve high water outlet temperature, simple and reasonable structure, and improve heat production Effect of water rate and thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

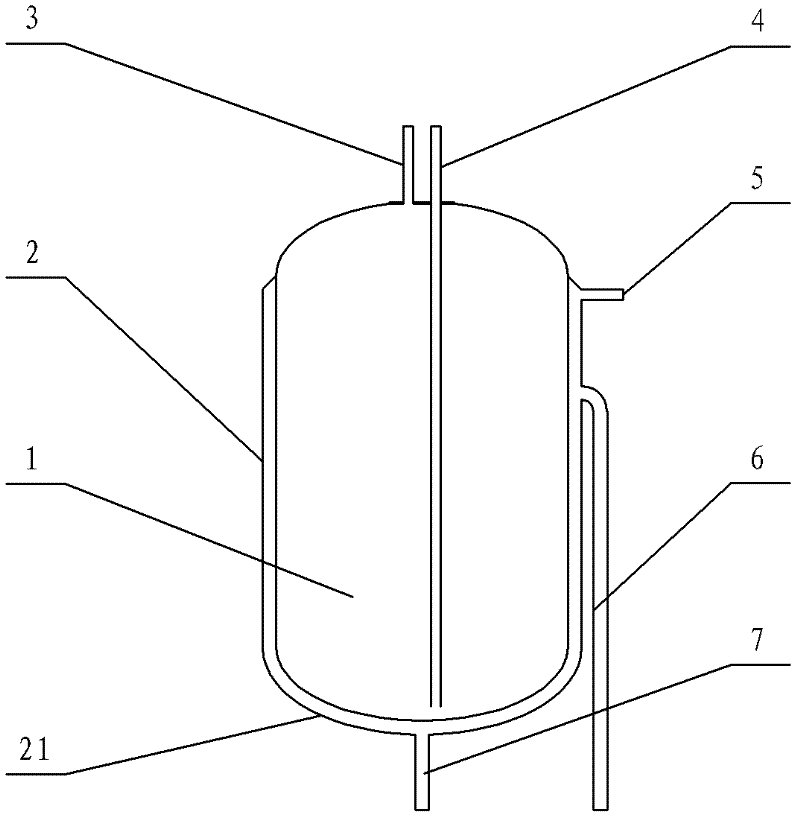

[0024] see figure 1 , the water tank with a jacketed heat exchanger includes a water tank liner 1 and a heat exchange jacket 2, the water tank liner 1 is provided with an outlet pipe 3 and a water inlet pipe 4, and the heat exchange jacket 2 is arranged in the middle of the water tank liner 1 The straight part and the bottom of the water tank liner 1. The water outlet pipe 3 is opened on the top of the water tank liner 1, and the water inlet pipe 4 is opened on the bottom of the water tank liner 1.

[0025] The heat exchange jacket 2 is provided with an upper circulation pipe 6 and a lower circulation pipe 7 , the upper circulation pipe 6 communicates with the middle of the heat exchange jacket 2 , and the lower circulation pipe 7 communicates with the bottom of the heat exchange jacket 2 . A ventilation pipe 5 is arranged on the heat exchange jacket 2 , and the ventilation pipe 5 is opened on the upper part of the heat exchange jacket 2 .

[0026] In this embodiment, one en...

no. 2 example

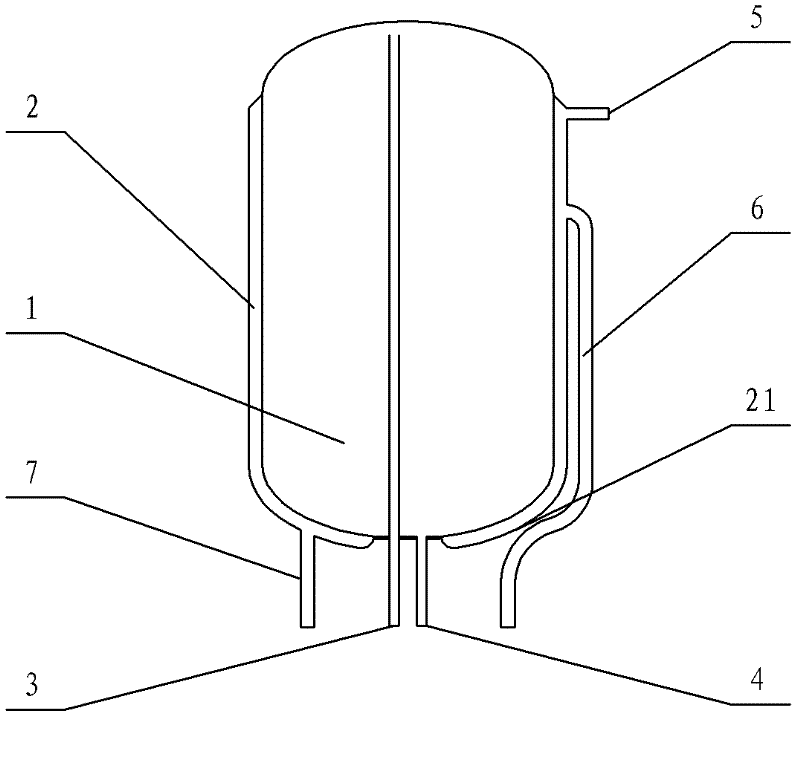

[0029] see figure 2 , In this embodiment, one end of the outlet pipe 3 extends into the water tank liner 1 and opens at the top of the water tank liner 1 . One end of the water outlet pipe 3 extends into the water tank liner 1 from the bottom of the water tank liner 1 . The bottom 21 of the heat exchange jacket 2 is similar in shape to the bottom of the water tank liner 1 , and the bottom of the heat exchange jacket 2 wraps the bottom part of the water tank liner 1 .

[0030] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

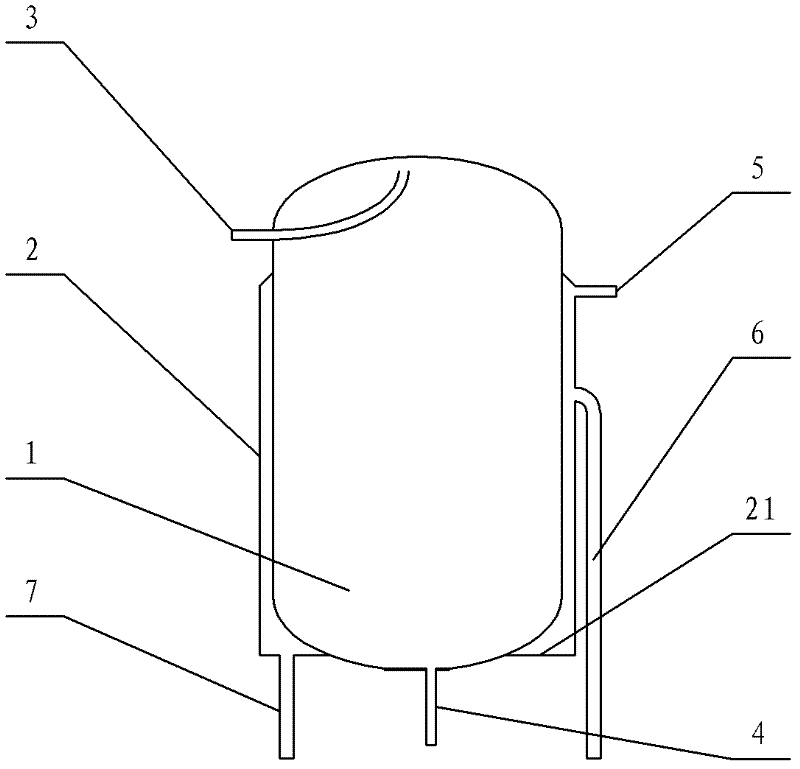

[0032] see image 3 , In this embodiment, one end of the outlet pipe 3 extends into the water tank liner 1 and opens at the top of the water tank liner 1 . One end of the water outlet pipe 3 extends into the water tank liner 1 from the side of the water tank liner 1 . The bottom 21 of the heat exchange jacket 2 is flat, and the bottom of the heat exchange jacket 2 wraps the bottom part of the water tank liner 1 .

[0033] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com