Airtightness test device and method for pressure container

A pressure vessel and experimental device technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the rate of increase and deceleration of fluid, can solve problems that do not involve the utilization of high-energy gas, so as to improve utilization, save energy, The effect of improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

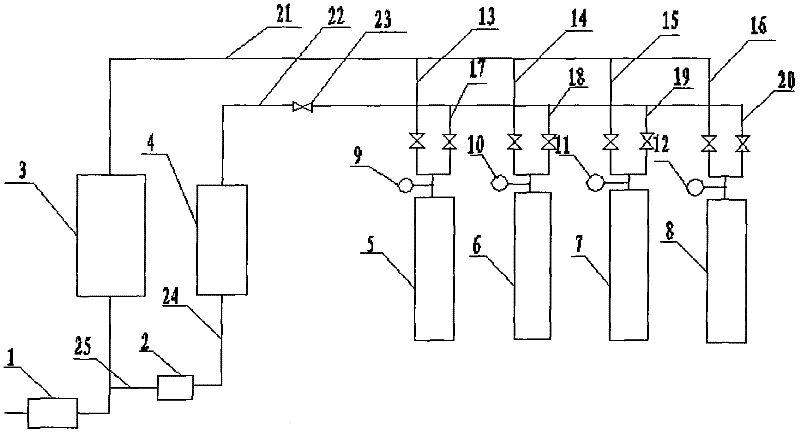

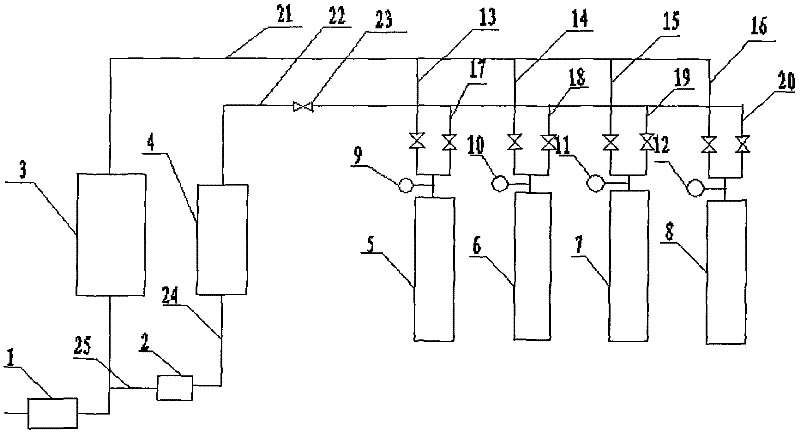

[0010] Step 1, initially all valves are closed;

[0011] Step 2, turn on the gas compressor 1, inflate the high-pressure gas storage tank 3, and turn off the gas compressor 1 after reaching the specified pressure;

[0012] Step 3, open the intake valve of the first test container 5, inflate the first test container 5, after reaching the test pressure, close the first test container 5 intake valve, and keep the pressure;

[0013] Step 4, when the pressure holding time of the first test container 5 is up, open the two-way valve of the first test container 5 and the two-way valve of the second test container 6 at the same time, so that the pressure in the first test container 5 is divided to the second test container. Two test containers 6, after the pressure difference in the first test container 5 and the second test container 6 reaches a preset value, close the intake valve of the second test container 6;

[0014] Step five, open the two-way valve of the third test container ...

no. 2 example

[0040] Test method of pressure vessel airtightness test device:

[0041] Step 1, initially all valves are closed;

[0042] Step 2, turn on the gas compressor 1, inflate the high-pressure gas storage tank 3, and turn off the gas compressor 1 after reaching the specified pressure;

[0043] Step 3, open the intake valve of the first test container 5, inflate the first test container 5, after reaching the test pressure, close the intake valve of the first test container 5, and keep the pressure;

[0044] Step 4, when the pressure holding time of the first test container 5 is up, open the two-way valves of all the test containers at the same time, so that the pressure in the first test container 5 is divided to other test containers. After the partial pressure is stable, close all the test containers. Two-way valve of the test vessel;

[0045] Step five, open the low-pressure gas storage tank valve 23, open the two-way valve of the first test container 5, pass the gas in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com