Machine vision light source luminance real-time regulating method and special system thereof in quality detection

A technology of machine vision and light source brightness, applied in the field of machine vision, can solve the problem that the brightness of the light source cannot be kept constant, and the control method cannot be controlled in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

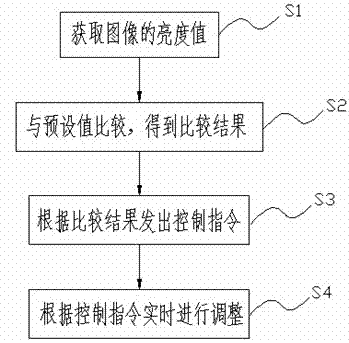

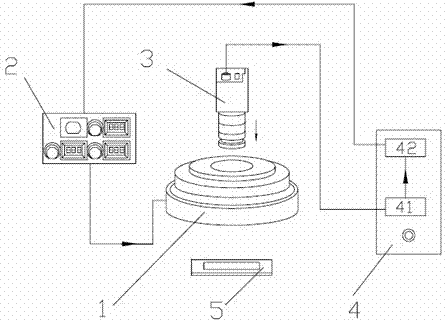

[0015] like figure 1 As shown, the present invention discloses a real-time adjustment method for the brightness of a machine vision light source in quality inspection, the method comprising:

[0016] 1) Connect the LED light source and the intelligent constant current controller as the working current source of the LED light source, and the intelligent constant current controller exchanges data with the computer;

[0017] 2) The working current of the light source is preset, and the intelligent constant current controller monitors the working current of the light source in real time. When the working current deviates, the intelligent constant current controller automatically performs current compensation to keep the light source working in a constant current state;

[0018] 3) It is achieved by the following measures, that is, when the LED light source directly illuminates the detected object, the image of the detected object is obtained, and the RGB value of the captured pict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com