Waterproof zipper and method of applying a fluid-tight coating to a cloth tape

A waterproof zipper and cloth tape technology, applied in the field of zippers, can solve the problems of uncontrollable lip or rib abutment, non-uniform abutment, fluid intrusion, etc., and achieve the effect of preventing mutual crossing, preventing slippage, and ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The invention will now be further elucidated by means of examples and with reference to the accompanying drawings.

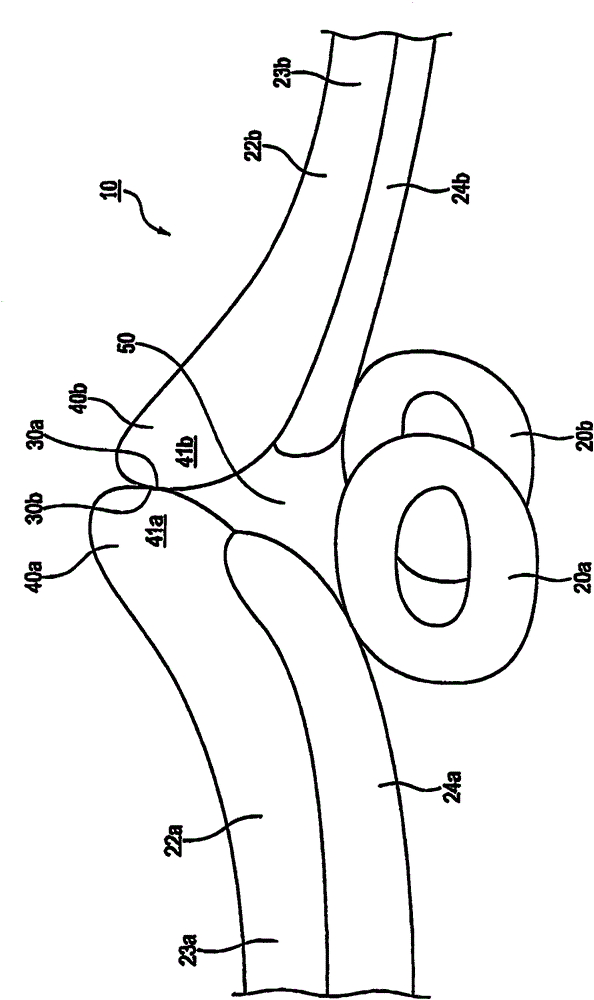

[0064] exist figure 1 , discloses a cross-sectional view of a prior art coil type slide fastener 10, wherein waterproof layers 22a and 22b are formed on one side of a pair of cloth tapes 24a and 24b, and coil type coupling elements 20a and 20b are mounted on a pair of The other side of cloth tape 24a and 24b.

[0065] Each of the helical coupling elements 20a and 20b is formed by winding a synthetic resin monofilament. Each of the coupling elements is constituted by a joint portion engaging with an opposing coupling element, an upper leg, a lower leg, and a turnover portion. The helical coupling elements 20a and 20b are sewn to the tapes 24a and 24b by sewing threads, or are knitted or woven to the tapes 24a and 24b when the tapes 24a and 24b are knitted or woven.

[0066] exist figure 1 , the coupling elements 20a and 20b are engaged with each other,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com