Liquid tank without free liquid level

A liquid tank, liquid level technology, applied in the direction of bulk cargo, etc., can solve problems such as controlling sloshing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

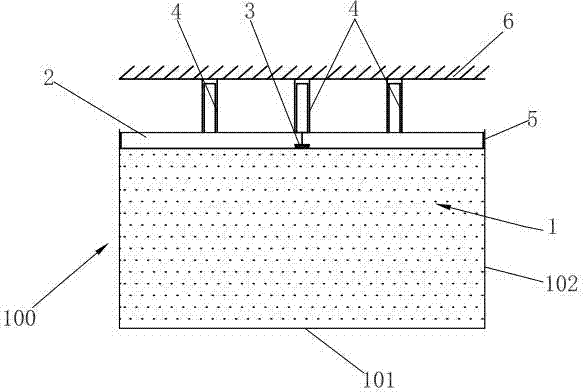

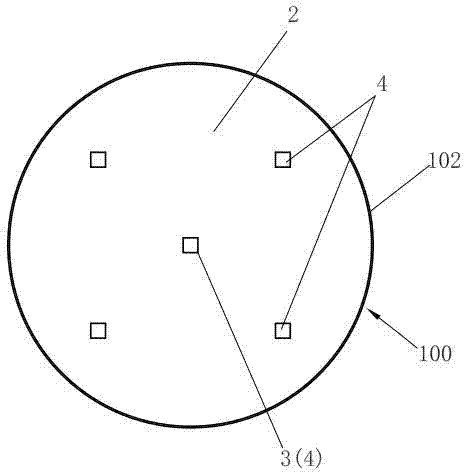

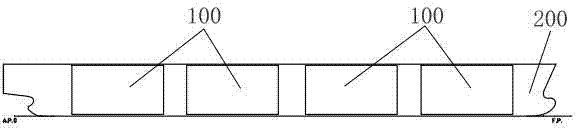

[0015] Such as figure 1 , 2 As shown, the non-free surface tank 100 includes a tank body 1, the tank body 1 is composed of a bilge 101 and a bulkhead 102 extending vertically upward around the bilge 101, and the cross section of the bulkhead 102 is circular, square or Other polygons, the hatch cover 2 is movably installed on the top of the liquid tank body 1, the shape of the hatch cover 2 is adapted to the shape of the bulkhead 102, the hatch cover 2 matches the inner side of the bulkhead 102 and is provided with a sealing ring 5, the hatch cover 2 The inner side is provided with the probe 3 of the dielectric constant measuring instrument, which is used to measure the dielectric constant of the material near the upper surface of the liquid in the liquid tank, and use the dielectric constant to judge whether a free liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com