Double suction pump mechanical seal flow equalizing ring for heat supply network circulation

A double-suction pump and flow ring technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problems of impurity accumulation, small particles, coking, etc., to extend the service life, enhance the Sealing performance, the effect of avoiding the accumulation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

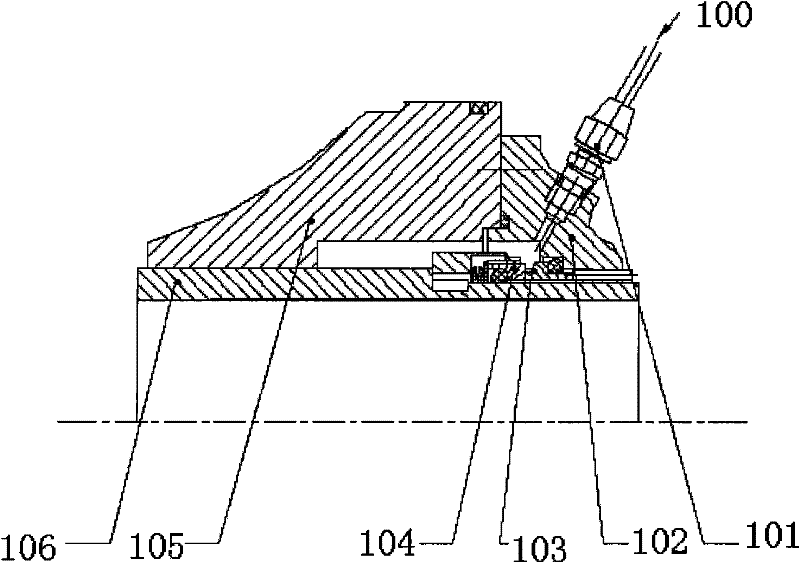

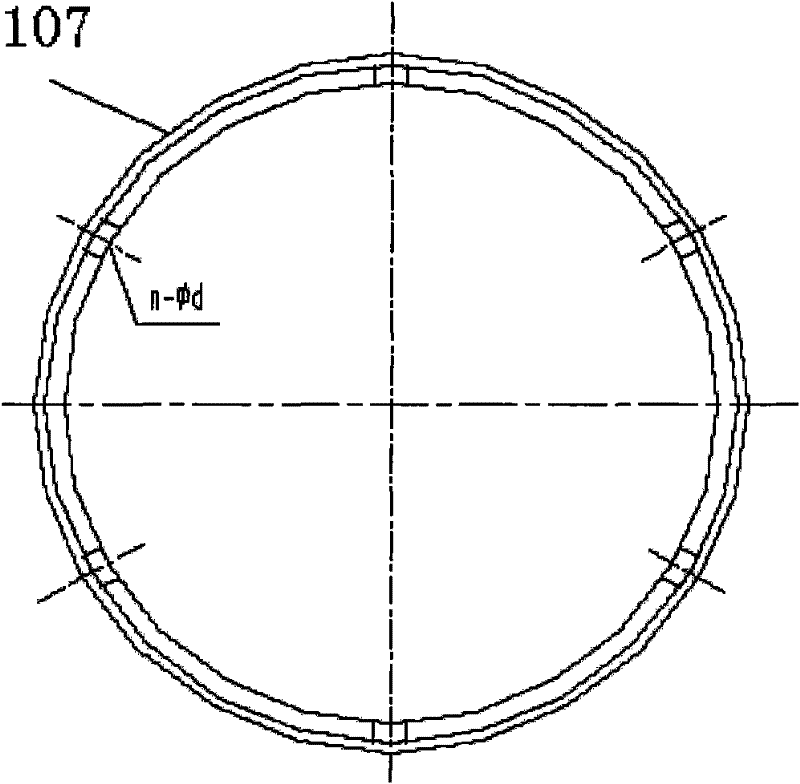

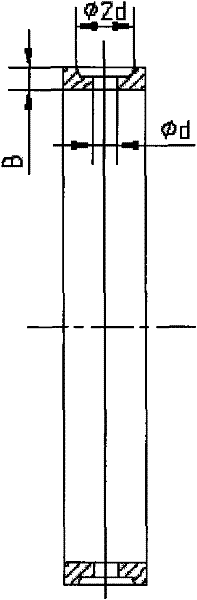

[0013] Depend on Figure 2A , Figure 2B , image 3 , Figure 4 It can be seen that in the double-suction pump mechanical seal flow equalizing ring for heat network circulation of the present invention, the described flow equalizing ring 107 is fixed in the mechanical seal gland 102 or the mechanical seal cavity 105; the shape of the described flow equalizing ring is A circular ring with a thickness B of 24mm-26mm and a trapezoidal groove in section is evenly arranged with n=6-8 through holes on the circumference, and the diameter of the through holes is d=8-10mm.

[0014] image 3 , Figure 4 Middle: mechanical seal flushing liquid 100, mechanical seal flushing pipe 101, mechanical seal static ring 103, mechanical seal dynamic ring 104, mechanical seal shaft sleeve 106 and inlet section A of mechanical seal flushing liquid.

[0015] Fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com