Method for producing circuit board containing stepped blind hole

A manufacturing method and circuit board technology, which are applied in the direction of electrical connection formation of printed components, etc., can solve problems such as difficulty in liquid medicine exchange, quality problems of blind holes, failures, etc., and achieve the effect of avoiding blind hole opening and blind hole blackening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

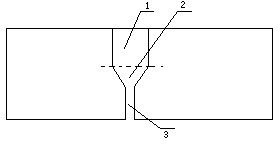

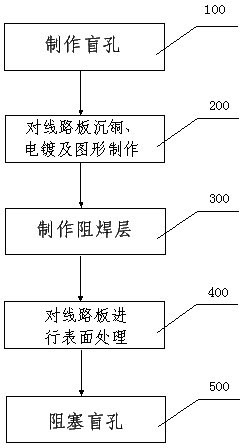

[0018] Such as figure 1 As shown, the specific embodiment of the present invention is: build a kind of circuit board that contains blind hole, comprise blind hole, described blind hole is stepped hole, and blind hole top 1 is cylindrical hole, and blind hole bottom 2 is tapered hole , the tapered hole is an inverted cone, and the tapered portion of the tapered hole is the lower end of the blind hole. The specific implementation process of the present invention is: when making the circuit board containing blind holes, make the blind holes into a stepped hole shape, that is, the upper part 1 of the blind hole is a cylindrical hole with a large aperture, and the lower part 2 of the blind hole is a tapered hole. The aperture is small. When the technical solution of the present invention is used for electroplating and nickel-gold surface treatment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com