Production method of crispy pear slices

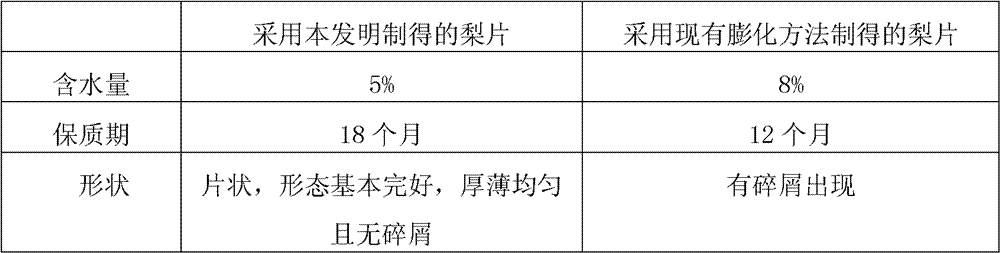

A production method and technology of pear slices, which are applied in the field of food processing, can solve problems such as color damage, influence on product flavor, and human health hazards, and achieve the effects of avoiding shrinkage, deformation or even distortion, facilitating popularization and utilization, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] One, the production method of pear chips, the steps are as follows:

[0039]1. Raw material processing: mechanically peel fresh, pest-free eight to nine mature golden pears; slice the peeled pears axially, with a slice thickness of 5mm;

[0040] 2. Color protection: Put the cut pear slices into 1wt‰ sodium bisulfite solution and soak for 30 minutes; then remove the color protection solution on the surface of the pear slices with clean water;

[0041] 3. Blanching: Blanch with 100°C hot water for 30s, drain,

[0042] 4. Freezing: freeze the blanched pear slices in step 3 at -10°C for 24 hours; put the frozen pear slices into a 5 wt% maltodextrin solution for 24 hours, soak the pear slices with Wash off the maltodextrin on the surface with clean water, and drain;

[0043] 5. Pressure difference puffing: spread the 20 kg pear slices processed in step 4 evenly on the material tray of the puffing tank, then put them into the puffing tank for pressure difference puffing, op...

Embodiment 2

[0056] The production method of pear chips, as described in Example 1, the difference is:

[0057] In step 1, the slice thickness of pear slices is 7mm; in step 2, put the cut pear slices into 3wt‰ sodium bisulfite solution for 30 minutes; The blanched pear slices were frozen at -18°C for 24 hours; the frozen pear slices were soaked in 10wt% maltodextrin solution for 20 hours; in step 5, 25 kg of processed pear slices were processed in a single layer Evenly spread on the material tray of the expansion tank; the drying process in step 6 is to reduce the temperature in the expansion tank to 60°C, vacuum dehydration for 1 hour, and the pressure during vacuum dehydration is 0Mpa; in the drying process, repeat the moisture removal step 8 times .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com