Homotaxial magnetic turning column liquid level meter

A magnetic flipping column and liquid level gauge technology, applied in the field of liquid level gauges, can solve the problems of magnetic float 2 stuck, damaged, and difficult to handle, and achieve the effect of not easy to get stuck and damaged, no valve leakage, and expanded measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

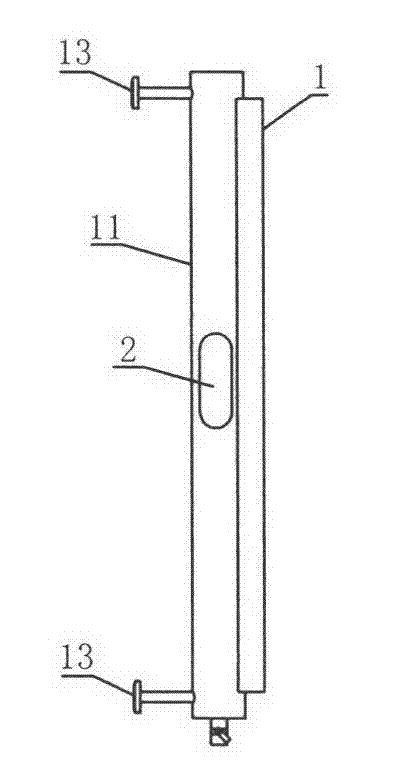

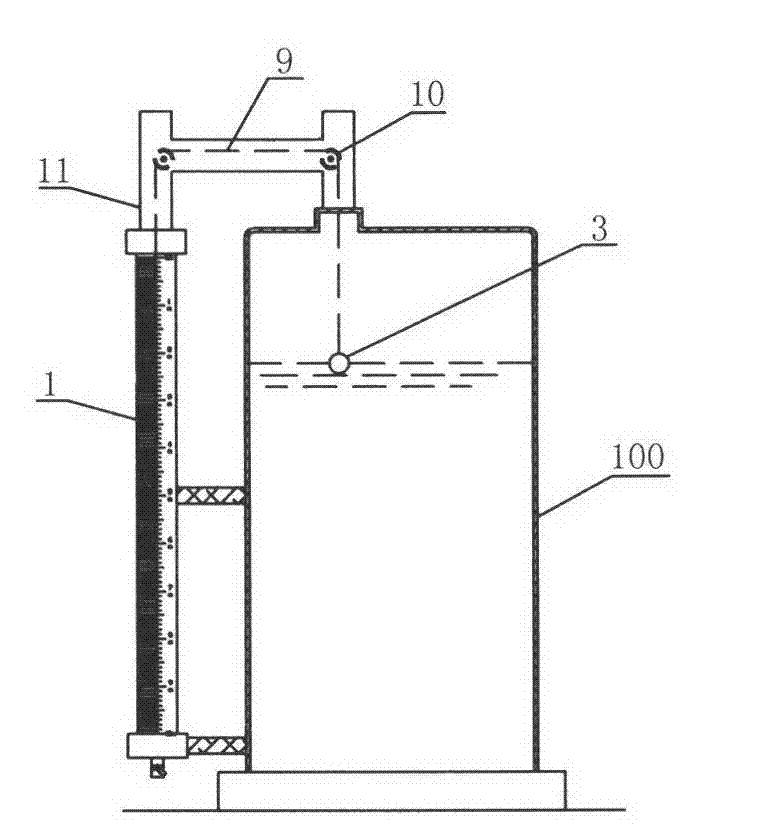

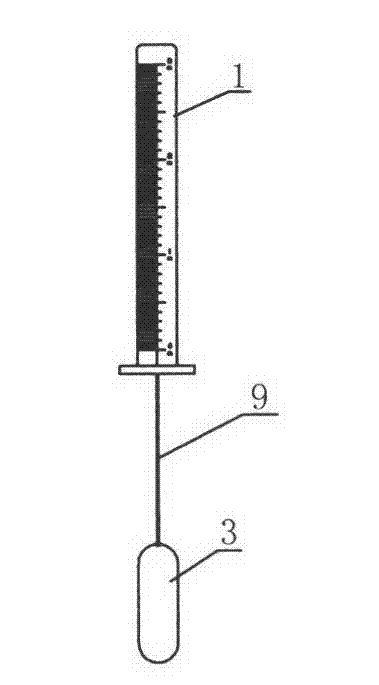

[0027] The uniaxial magnetic column liquid level gauge of this embodiment is as follows: Figure 4 and Figure 5 As shown, it includes a magnetic turning column 1, a magnetic float 2 parallel to the magnetic turning column 1 and a floating body 3 arranged on the surface of the liquid to be tested. It also includes a transmission mechanism 4 and a hammer body 5. The transmission mechanism 4 is mainly composed of a single rotating shaft 7 arranged in the housing 6 and two runners 8-1 and 8-2 sleeved on the rotating shaft 7. The floating body 3 passes The rope 9 and the pulley 10 are wound around the first runner 8-1, and the magnetic float 2 and the hammer body 5 are wound around the both sides of the second runner 8-2 by the rope 9, as Image 6 shown.

[0028] like Figure 5 As shown, the single-axis magnetic flip column liquid level gauge of this embodiment also includes a magnetic float cavity 11 and a hammer body cavity 12 that are parallel to the magnetic flip column 1. ...

Embodiment 2

[0050] The uniaxial magnetic column liquid level gauge of this embodiment is as follows: Figure 7 Shown, is the improvement on the basis of embodiment one, and its structure is basically the same as embodiment one, and difference is: 1) the running wheel that is sleeved on the rotating shaft 7 is three (promptly two in embodiment one Add a runner on the runner basis), respectively the first runner 8-1, the second runner 8-2 and the third runner 8-3; 2) the magnetic float 2 is wound around the second runner by the rope 9 Then 8-2 is wound around, and hammer body 5 is wound around with third runner 8-3 by rope 9.

[0051] Generally, the rope 9 connecting the magnetic float 2, the floating body 3 and the hammer body 5 will be pre-wound a certain number of turns (more than one turn) on the runners 8-2, 8-1, 8-3 respectively.

Embodiment 3

[0053] The uniaxial magnetic column liquid level gauge of this embodiment is as follows: Figure 8 What is shown is a change based on the second embodiment, and its structure is basically the same as that of the second embodiment, except that the transmission mechanism 4 is fixed on the container 100 containing the liquid to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com