Mutual inductor automation detecting system

A fully automated, transformer technology, used in instruments, measuring devices, measuring electrical variables, etc., can solve the problems of not meeting the requirements of transformer verification, and not reflecting the advantages of automated assembly line operations, to improve stability and accuracy, Easy to manage and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

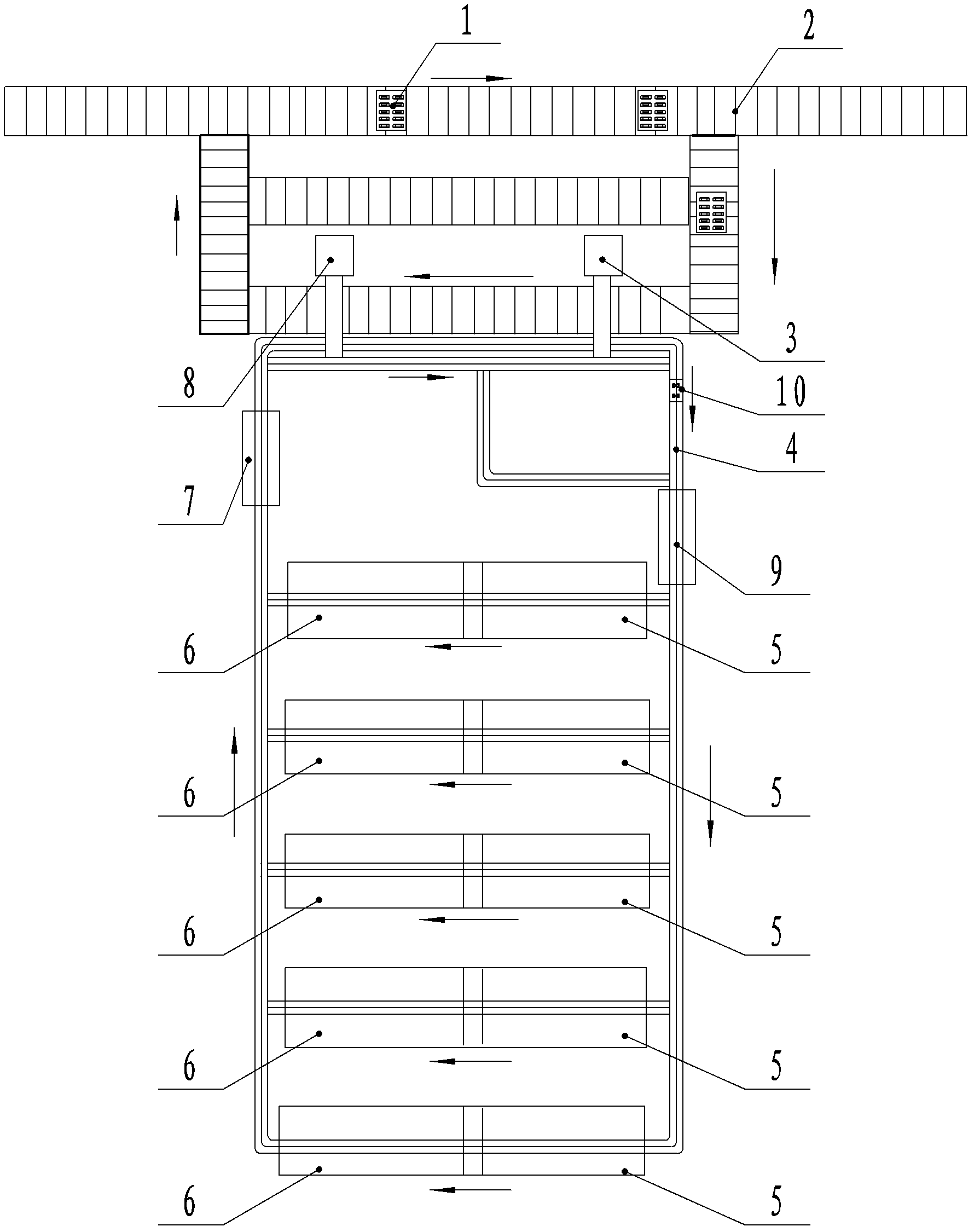

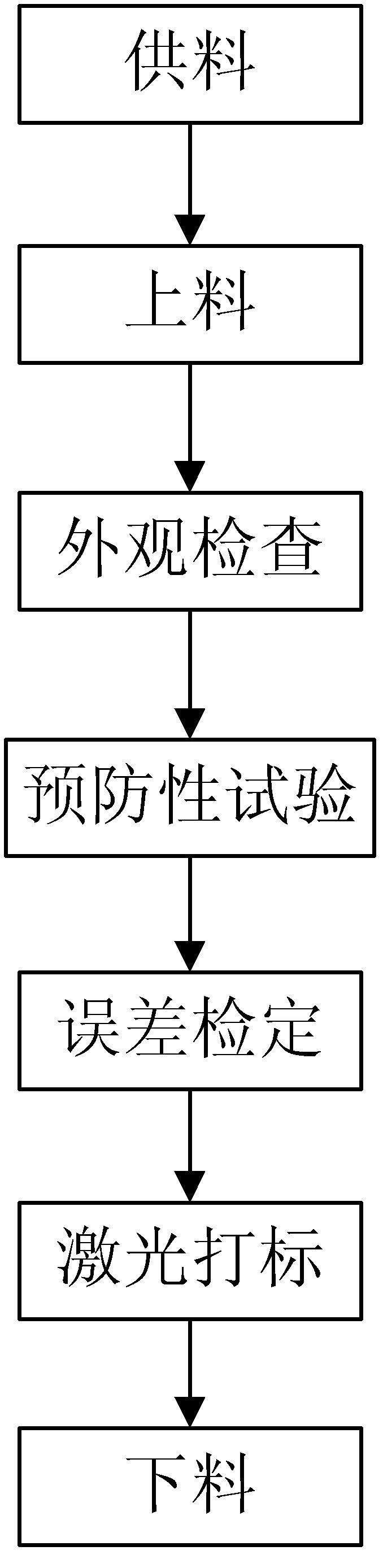

[0031] The present invention is used for transporting the turnover box 1 to transport the turnover box 1 equipped with the transformer to be inspected from the storage system to the loading station and transport the turnover box 1 equipped with the inspected transformer located at the unloading station back to the storage system The feeding conveying line 2 of the feeding conveying line; the feeding device 3 located next to the feeding station of the feeding conveying line 2 for moving the transformer located at the feeding station of the feeding conveying line 2 to the verification conveying line 4; The transformer is moved to the verification transmission line 4 of the corresponding station of each device; the appearance inspection device 9 is used to take pictures of the appearance of the transformer and handle it; the inspection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com