Inspection system based on mobile inspection apparatus of transformer station and inspection method thereof

An inspection system and mobile technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve problems such as damage to the shell and equipment, lack of convincing diagnostic conclusions, and the inability of the mobile inspection device to be combined with a video monitoring system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

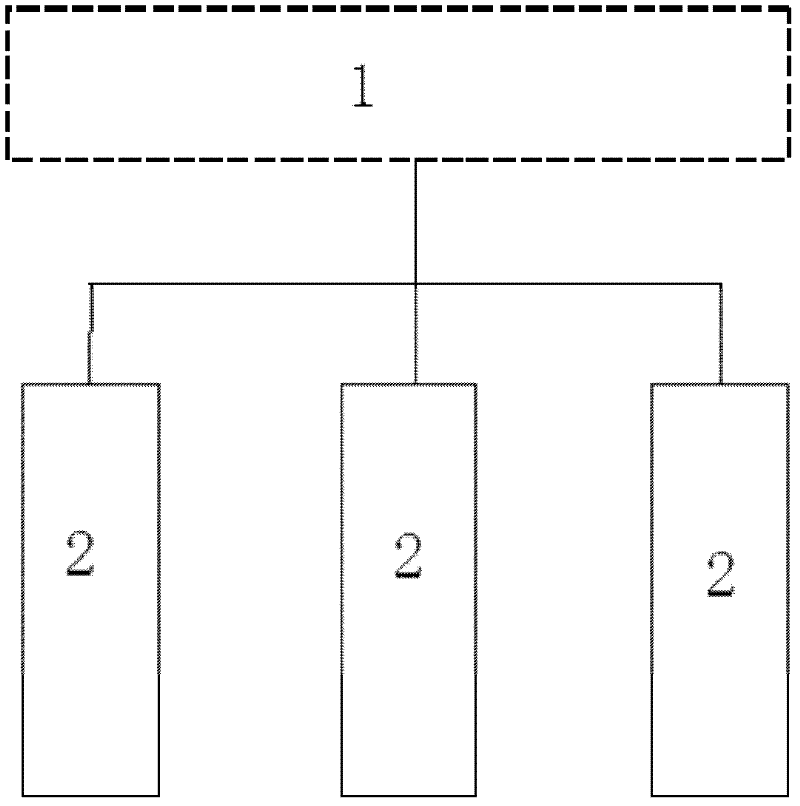

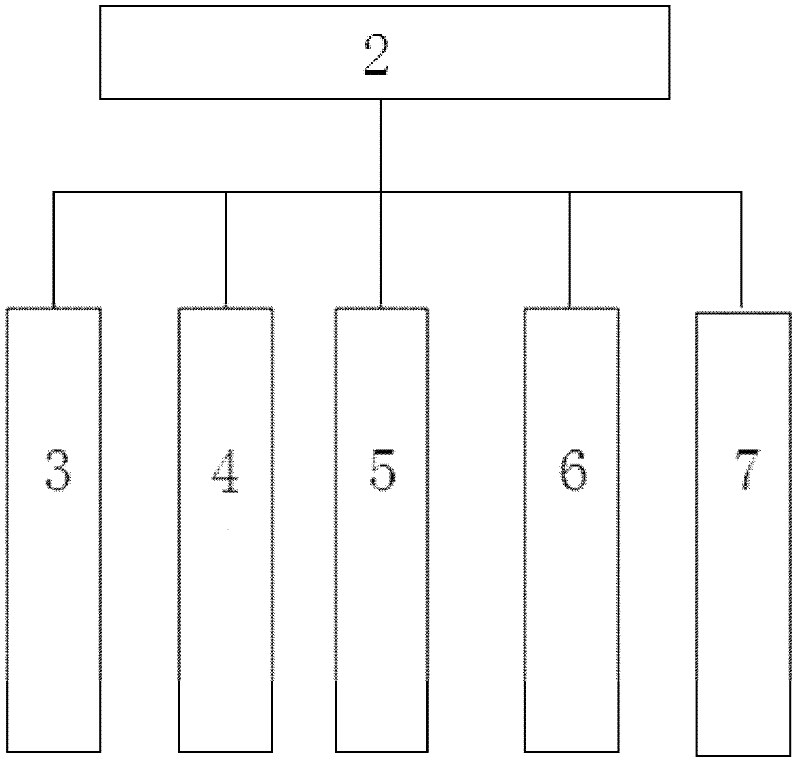

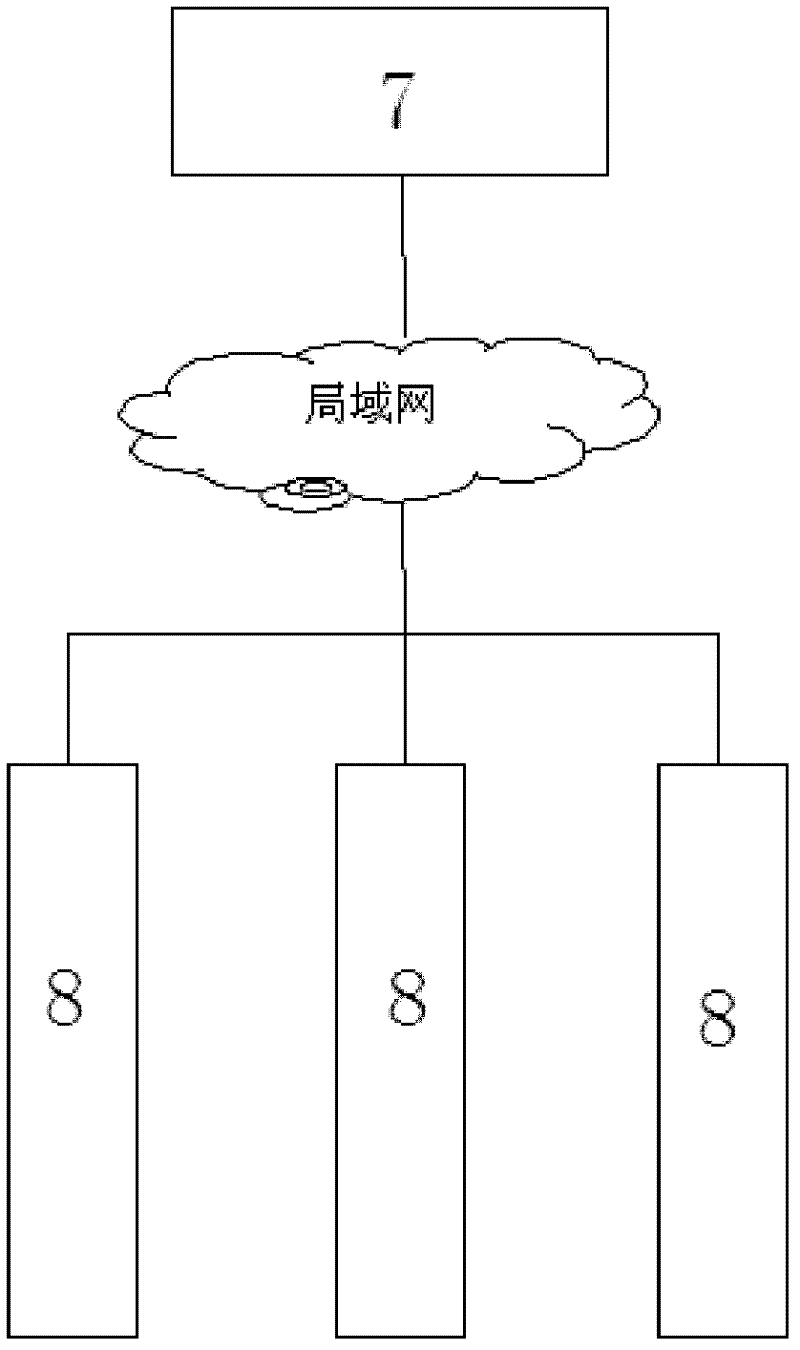

[0077] figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 Among them, an inspection system based on a substation mobile inspection device, which includes a monitoring center 1, and the monitoring center 1 is connected to the station-level mobile inspection device intelligent inspection system 2 of at least one substation through a network; Each station-level mobile inspection device intelligent inspection system 2 includes at least one base station 29, and the base station 29 communicates wirelessly with at least one mobile inspection device 5; at the same time, there is at least one mobile inspection device charging facility in the substation 4. In the substation, there is also a mobile inspection device navigation and positioning facility 3 for walking that is matched with the mobile inspection device 5. At the same time, an environmental information collection subsystem 6 is also installed in the substation. The fixed-point auxiliary monitoring subsyste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com