Multifunctional substation intelligent robot inspection system

An intelligent robot and inspection system technology, applied in electrical components, circuit devices, etc., can solve the problems of labor-intensive manual inspection, inability to interact with the substation sequence control platform, and equipment failures that cannot be detected and discovered in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

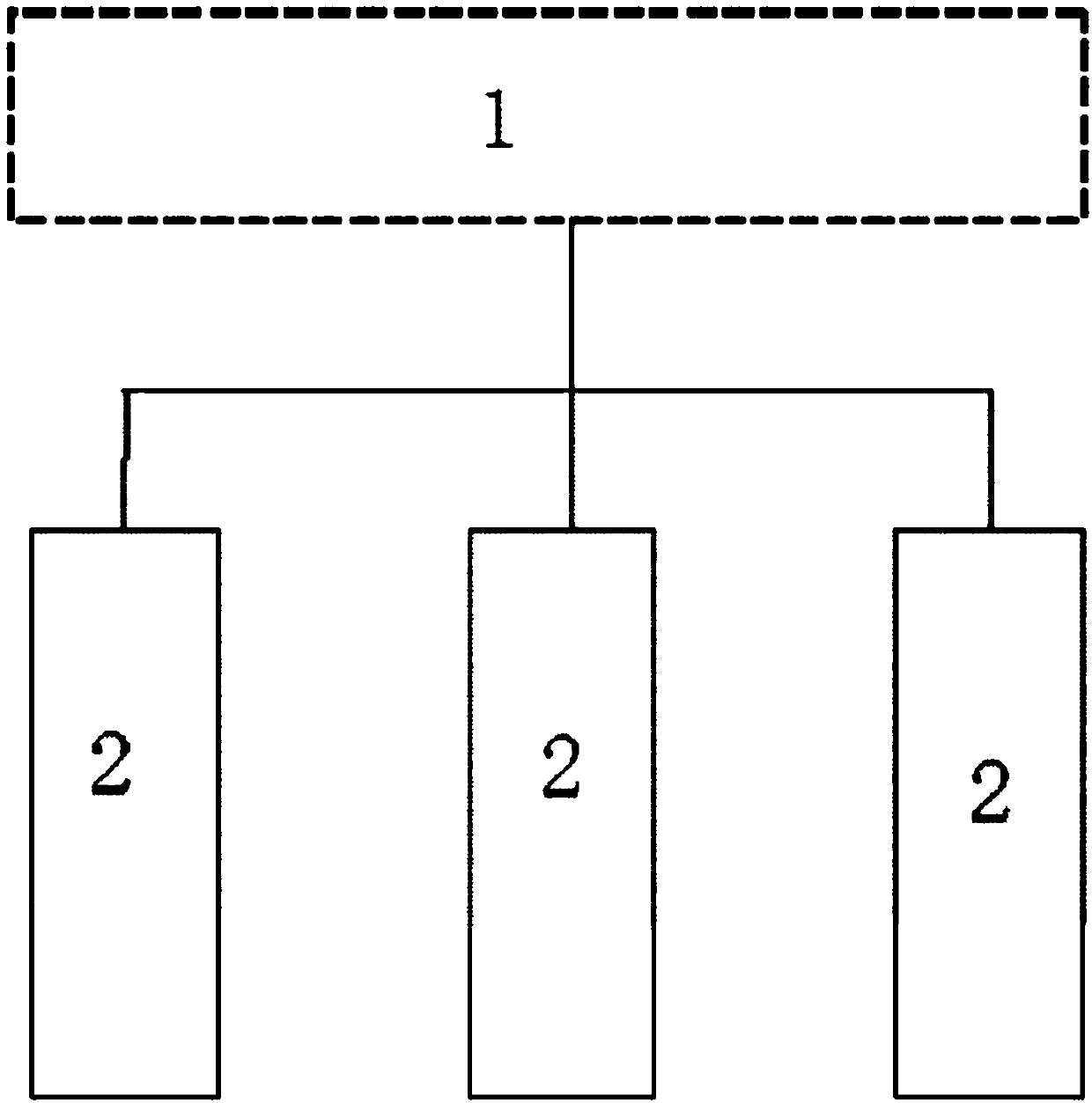

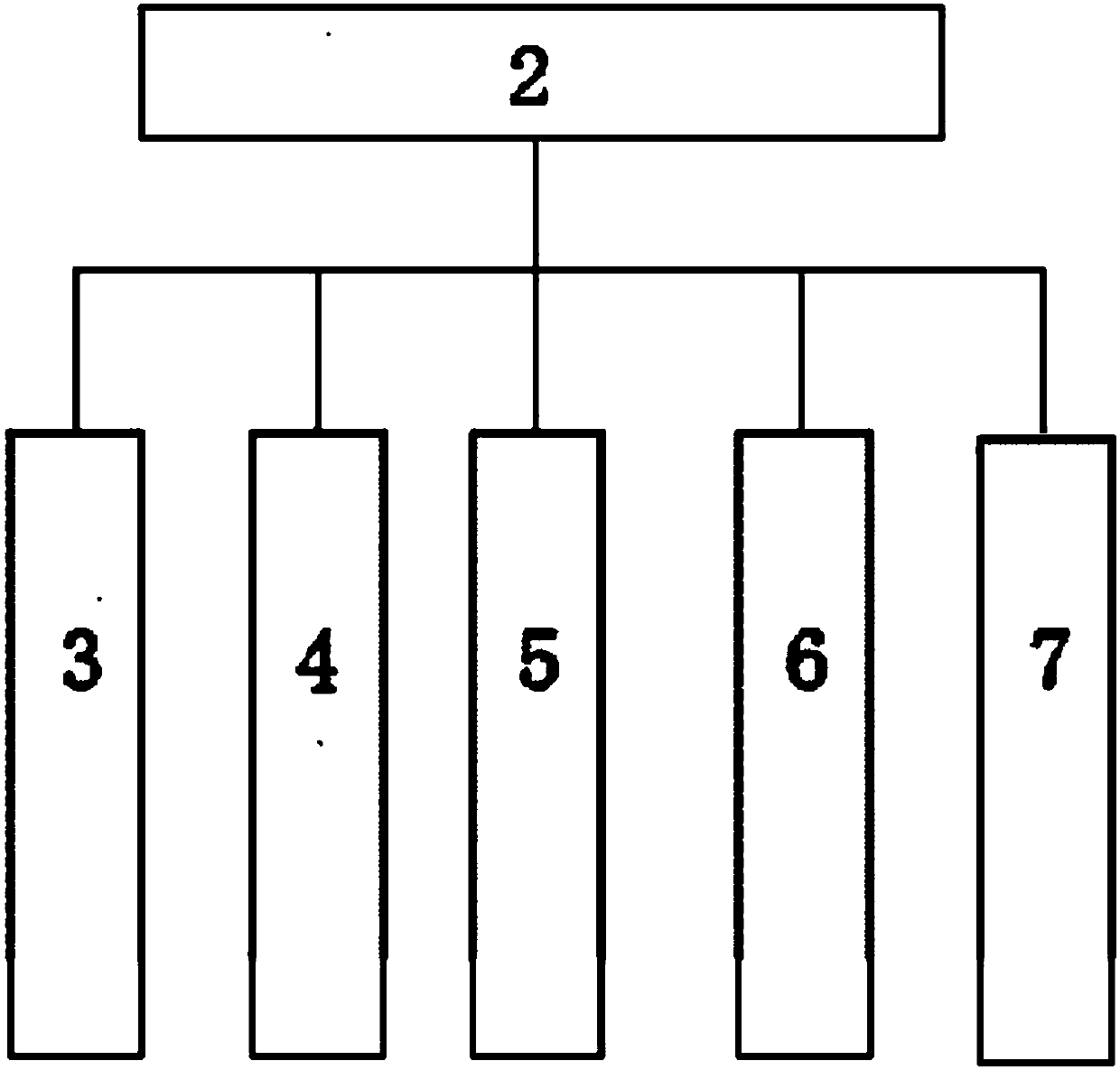

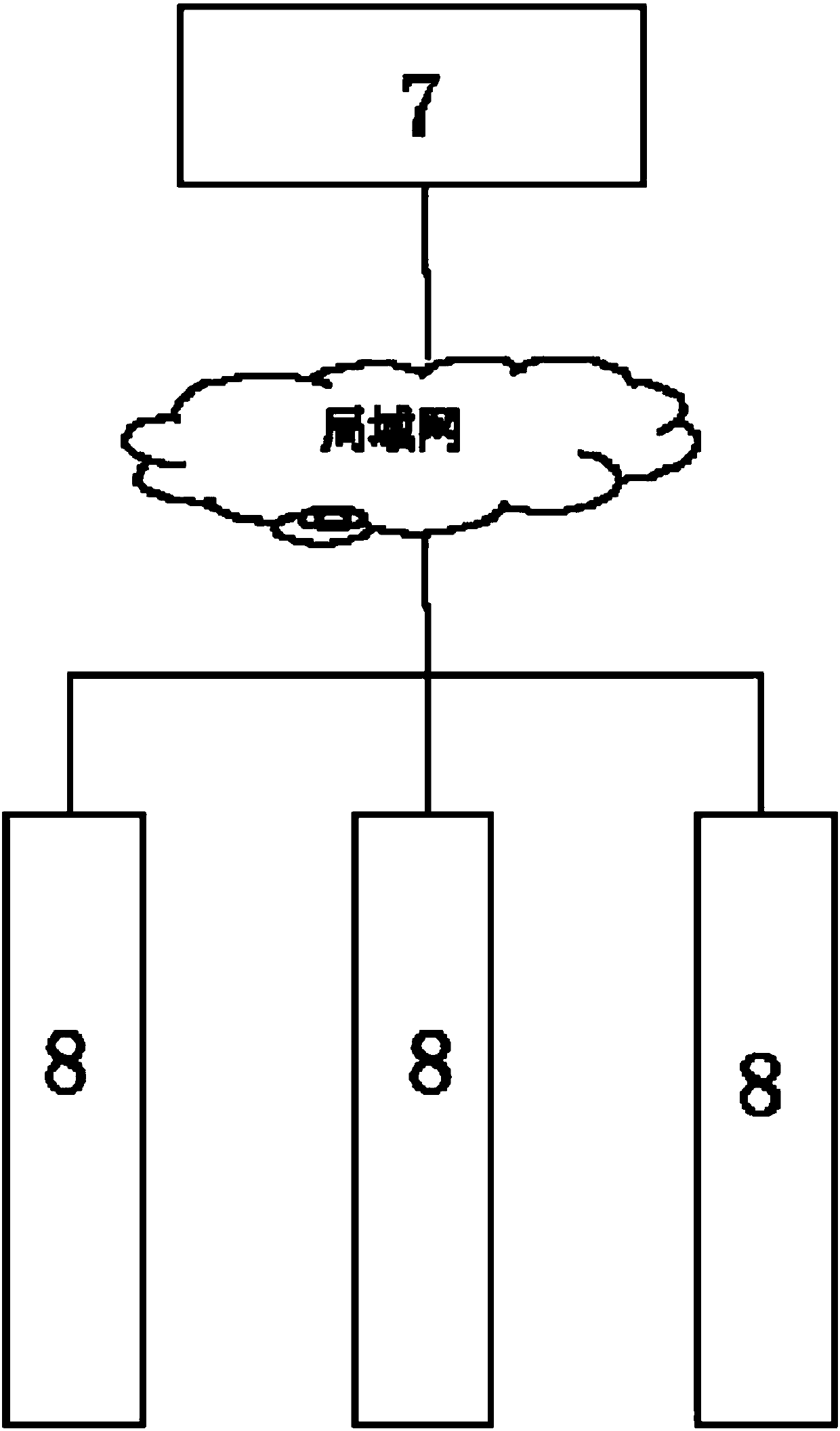

[0077] figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Figure 7 Among them, a multifunctional substation intelligent robot inspection system, which includes a monitoring center 1, the monitoring center 1 is connected to the station-level robot intelligent inspection system 2 of at least one substation through a network; each station-level robot intelligent inspection system The system 2 includes at least one base station 29, and the base station 29 communicates wirelessly with at least one intelligent inspection robot 5; at the same time, at least one robot charging facility 4 is provided in the substation, and a battery that matches the intelligent inspection robot 5 is laid in the substation. A robot navigation and positioning facility 3 for walking, and an environmental information collection subsystem 6 and a fixed-point auxiliary monitoring subsystem 7 installed at each monitoring device in the substation; the environmental information collection subsystem ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com