Combined quick acting control valve for a steam turbine

A fast-closing, steam-turbine technology, applied in the direction of lift valves, sliding valves, valve details, etc., can solve the problems of large space requirements, large volume, high material input, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

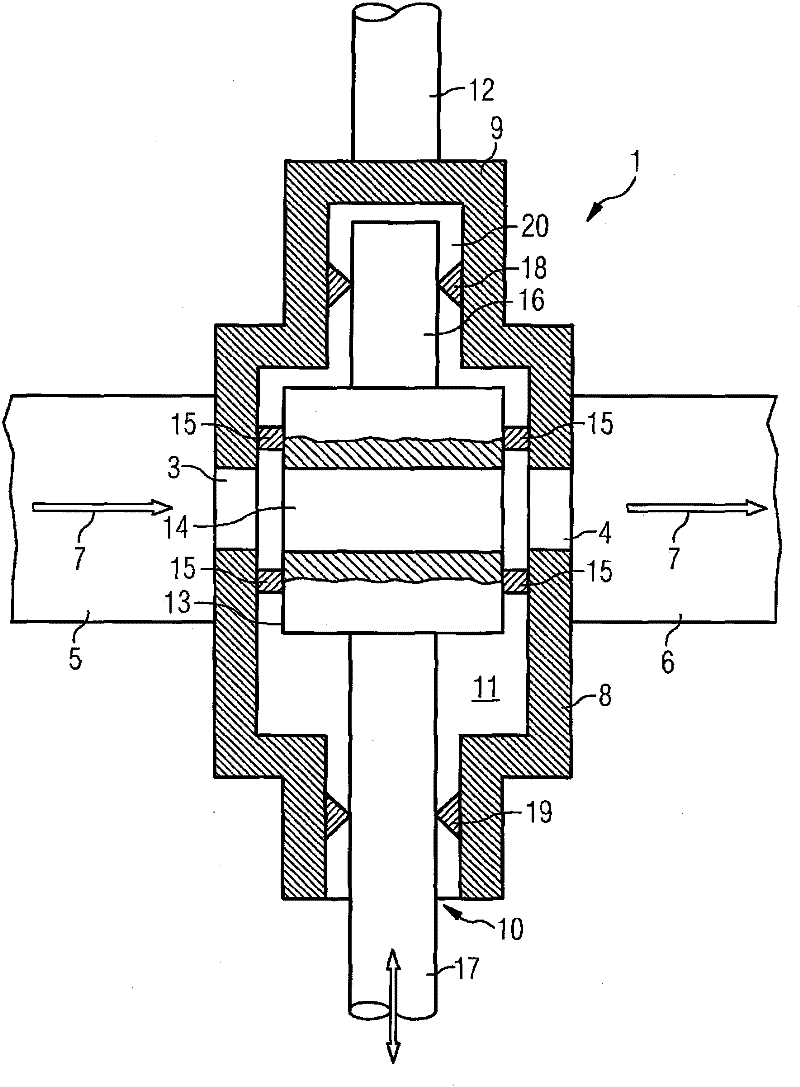

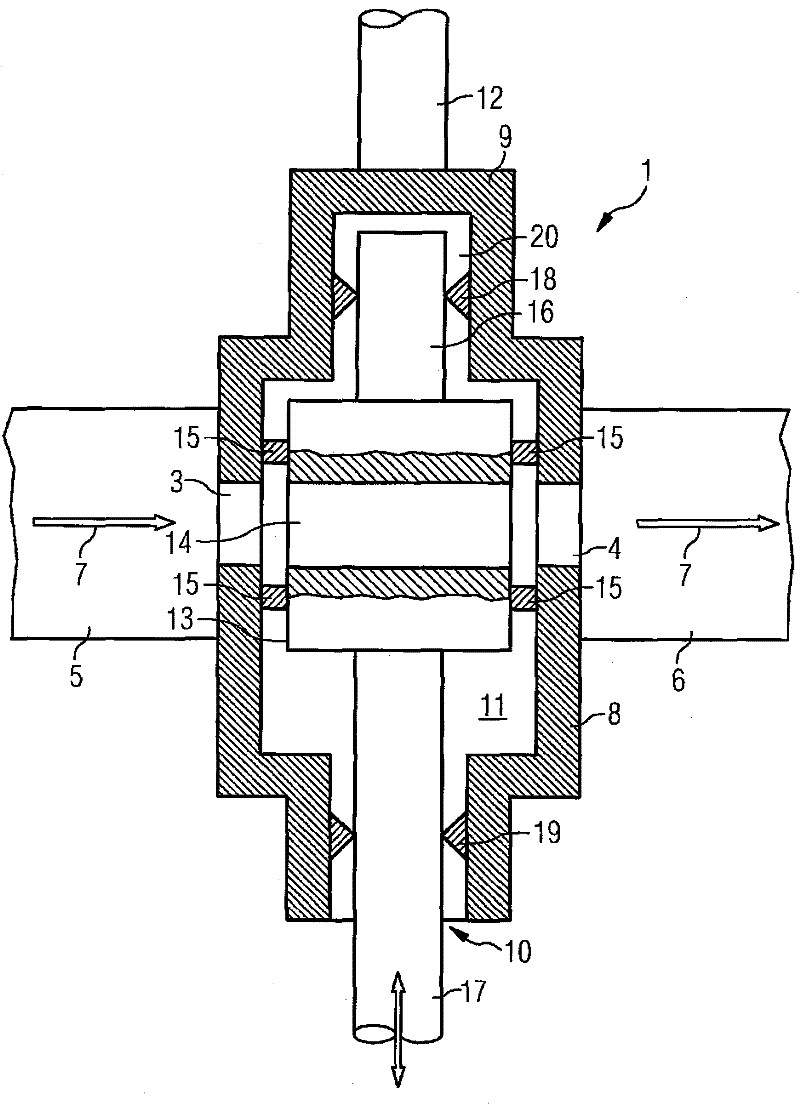

[0010] As can be seen from FIG. 1 , the quick-closing control valve 1 has a housing 2 which is designed cylindrically. In the cylindrical wall of the housing 2, said housing 2 has an inlet opening 3 and an outlet opening 4, wherein the center points of the openings 3, 4 lie on an imaginary line which is aligned with the cylindrical housing 2. The central axis extends vertically. On the inlet hole 3 an inflow channel 5 can be connected, and on the outlet hole 4 an outflow channel can be connected, so that a steam flow 7 is led to the inlet hole 3 through the inflow channel 5 and a steam flow 7 is discharged from the outlet hole 4 through the outflow channel 6 . If the quick-closing regulating valve 1 is installed on a steam turbine, the live steam connection of the steam turbine forms the outflow channel 6 , whereas the live steam line forms the inflow channel 5 .

[0011] The housing 2 is formed by a cylindrical section 8 which is closed on one side by means of a cover 9 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com