Flexible cigarette conveying device

A conveying device and cigarette technology, which is applied in the fields of tobacco, cigarette manufacturing, and application, can solve the problems of cigarette wrinkles, low production efficiency, affecting the appearance quality of cigarettes, etc., and achieves wrinkle resolution, production efficiency improvement, and full use of equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

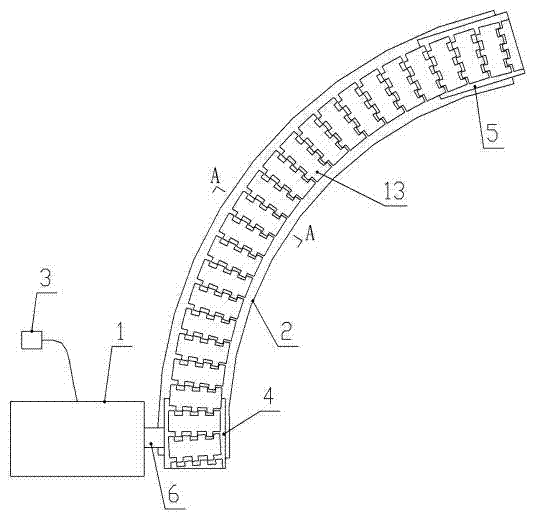

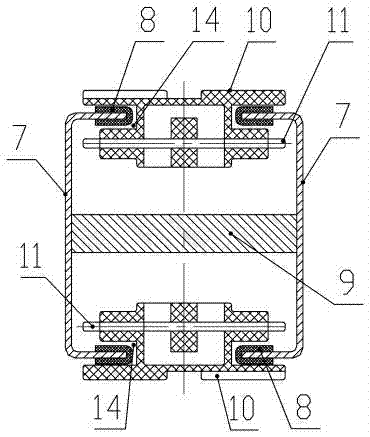

[0010] Such as figure 1 and figure 2 As shown, the flexible cigarette conveying device of the present invention includes a motor 1 and an arc-shaped support rail 2, the motor 1 is connected with a frequency converter 3 for controlling the speed of the motor 1, and the two ends of the support rail 2 are respectively provided with a driving wheel 4 and a driven wheel 5. The output shaft 6 of the motor 1 is connected to the driving wheel 4 in transmission, and a cigarette conveying mechanism is arranged between the driving wheel 4 and the driven wheel 5 . The supporting track 2 includes two parallel grooved guide rails 7 with openings opposite to each other. The upper and lower horizontal sections of each guide rail 7 are wrapped with a guide bar 8, and a support rod 9 is horizontally arranged between the two guide rails 7. . The cigarette conveying mechanism includes a chain 13 formed by connecting at least two chain plates 10 through pin shafts 11. The inner surface of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com