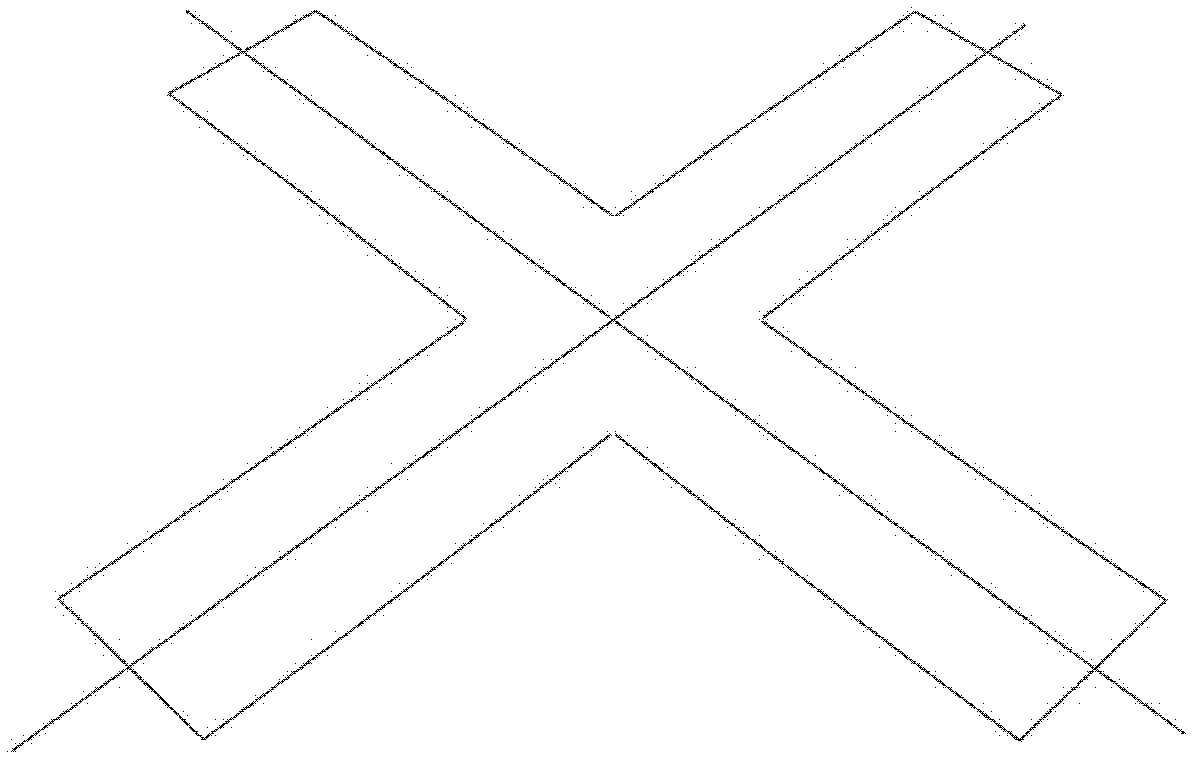

X-shaped bent colored ribbon and making method thereof

A technology of bending, twisting and ribbons, applied in the direction of building components, arched structures, dome roof structures, etc., can solve the problems of small distortion, deformation of curved panels, inability to meet large spans, etc., to achieve small errors, reduce weight, structure Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

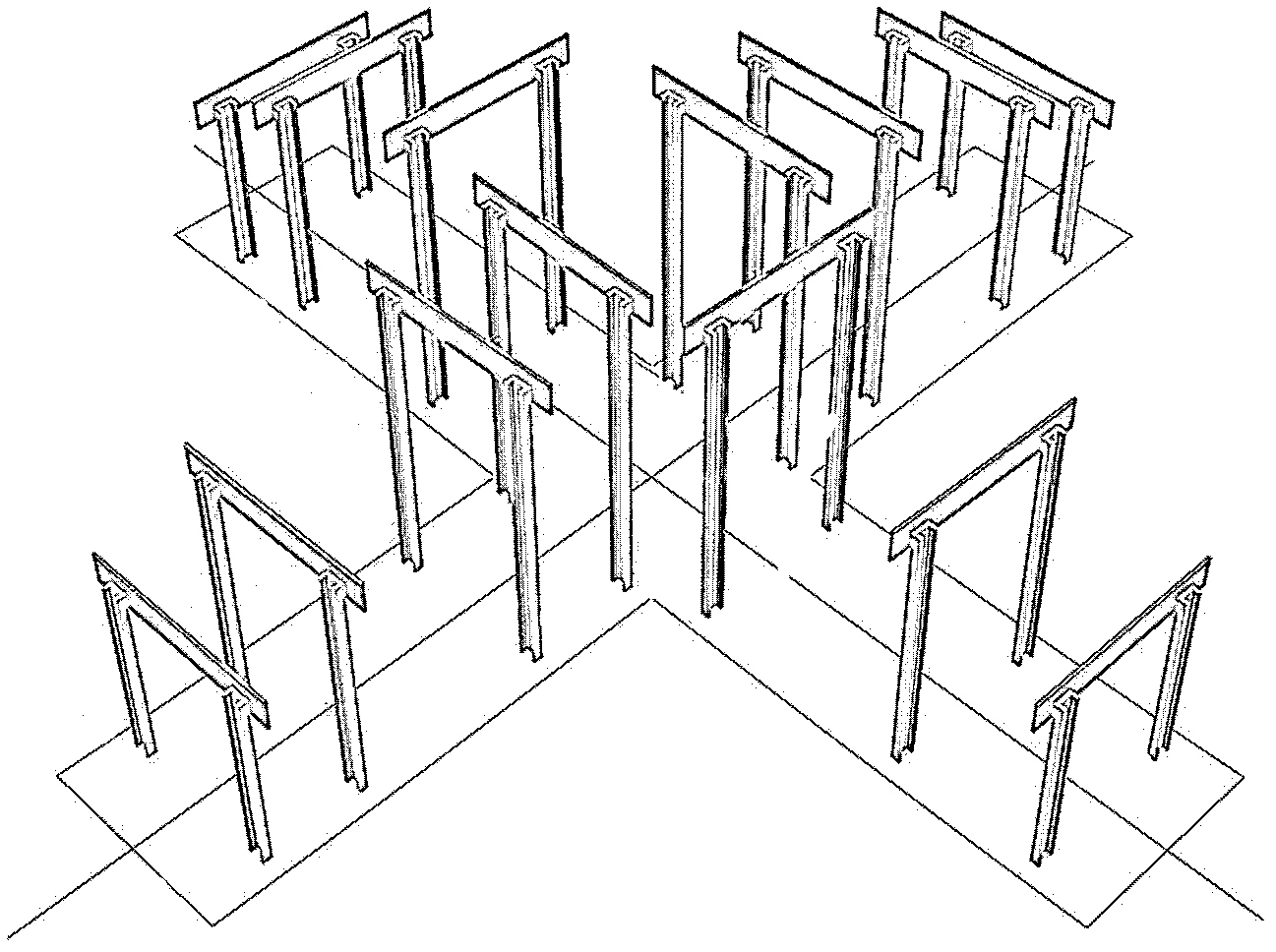

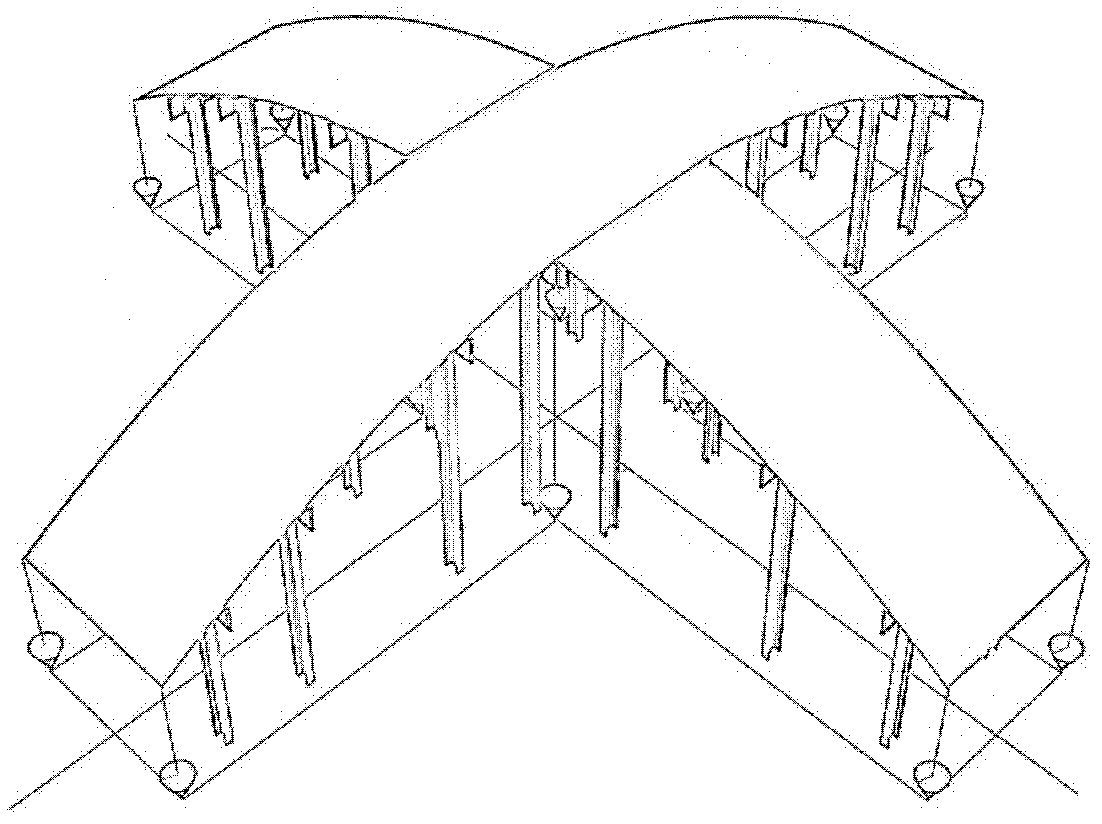

[0066] An X-shaped twisted ribbon, the X-shaped twisted ribbon is composed of three parts: middle part 1, left wing 2 and right wing 3; middle part 1, left wing 2 and right wing 3 are twisted steel columns; 3 Through assembly and welding, it is fixed into an X-shaped bent and twisted steel column.

[0067] The middle part 1 includes: a bottom plate A11, a diaphragm A12, a rib A13, a panel A14, and a side plate A15; the diaphragm A12 includes: a non-porous diaphragm 121 and a middle circular diaphragm 122;

[0068] The diaphragm A12 is vertically fixed on the upper surface of the bottom plate A11; the non-porous diaphragm 121 is fixed in the middle of the bottom plate A11; The rib plate A13 is vertically fixed on the bottom plate A11 and the diaphragm A12; the panel A14 is welded and fixed on the rib plate A13 and the diaphragm A12; the side plate A15 is fixed on both sides of the middle;

[0069] The left wing 2 comprises: a bottom plate B21, a transverse partition B22, a rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com