Temperature stress control expansion joint

An expansion joint and stress technology, applied in the direction of building and building structure, can solve the problems of lack of versatility of joints, limited bearing capacity, inconvenient engineering design and construction, etc., to achieve simple and fast installation process, strong bearing capacity and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

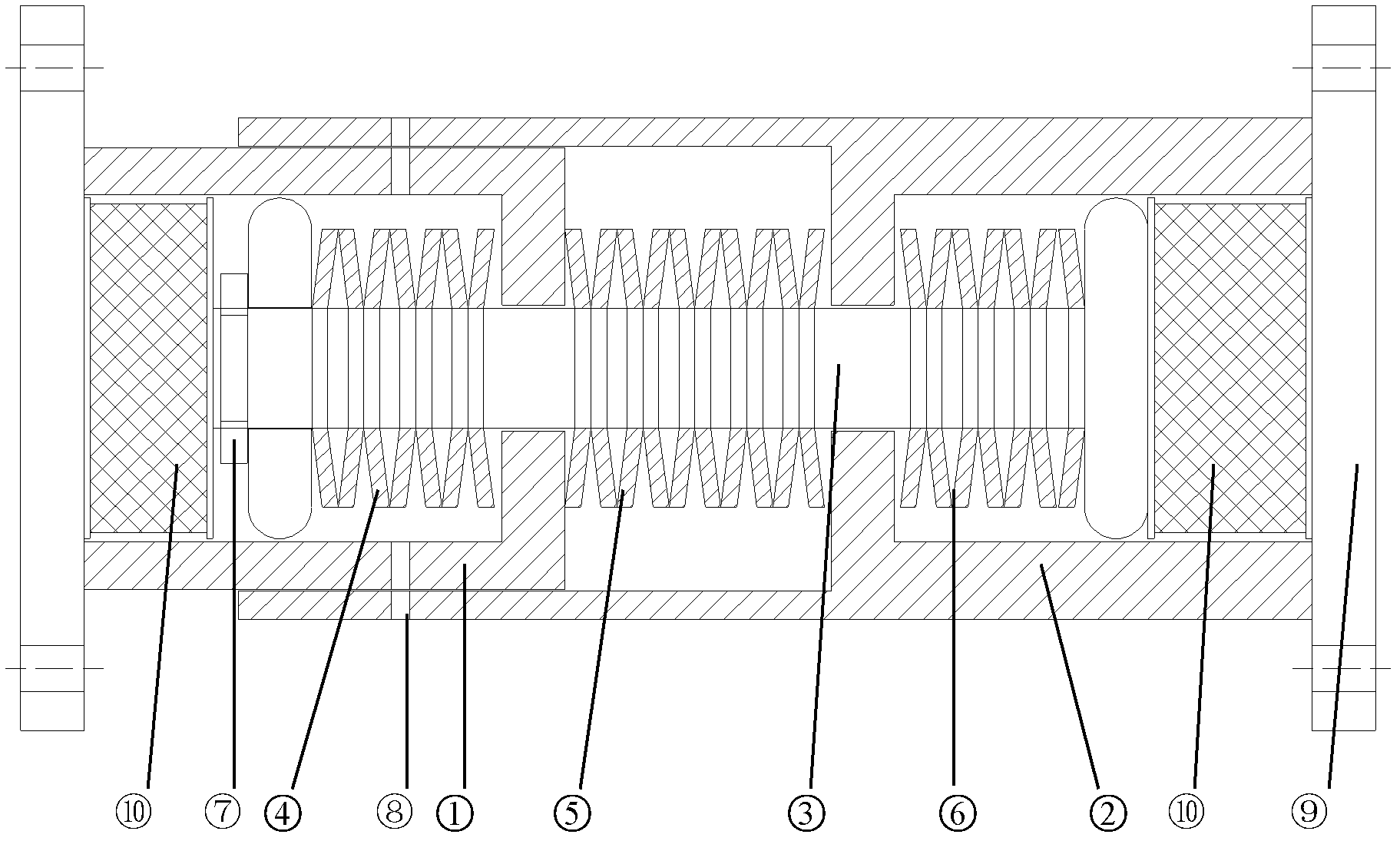

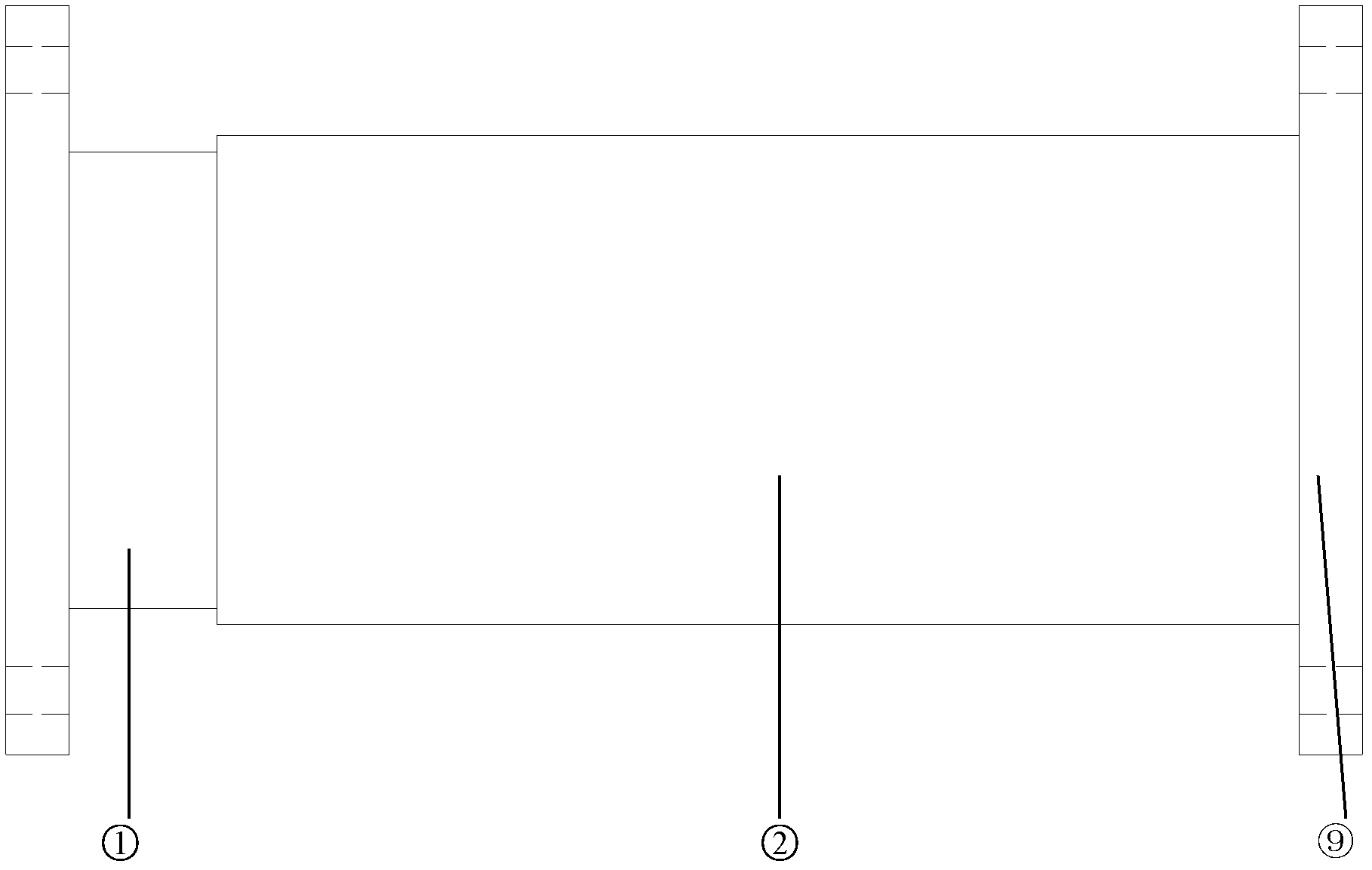

[0024] Attached below Figure 1-4 The structure and installation process of the present invention are described in detail.

[0025] First put the assembled disc spring (6) into the right end part of the center guide rod (3), then insert the right sleeve (2) into the center guide rod, then put the disc spring (5), left sleeve (1) Put the guide rods in sequence, temporarily fix the holes according to the pre-designed installation temporary holes (8), install the disc springs (4), and use the nuts (7) to fix the left end of the guide rods. After the installation is completed Remove the temporary fixation of the mounting hole and start working normally. The sectional view of the embodiment of the present invention sees figure 1 ; The elevation view of the embodiment of the present invention sees figure 2 .

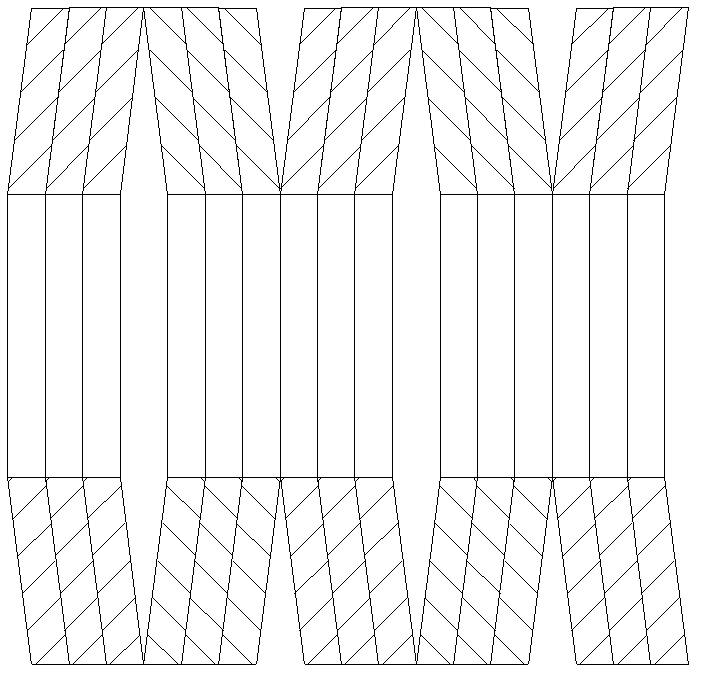

[0026] A temperature stress control expansion joint, including inner, middle and outer parts, the inner layer is an "I" type central guide rod (3), and the outer layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com